Preparation method and application of mixed oxide-doped nano copper-cobalt alloy catalyst

A technology of mixed oxides and catalysts, which can be used in metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, preparation of hydroxyl compounds, etc., which can solve the problems of long-term stability of carbon materials and the unfavorable formation of Cu-Co Alloy, reduce catalyst selectivity and other issues, to achieve the effect of low cost, improved stability, and not easy to sinter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

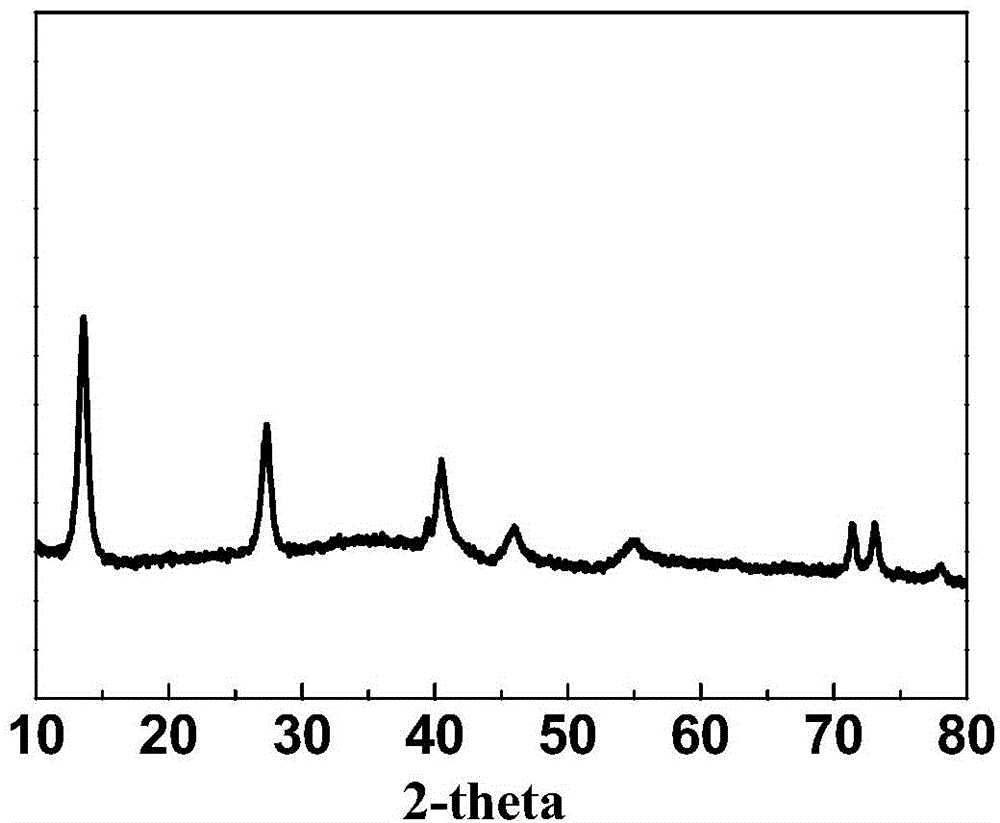

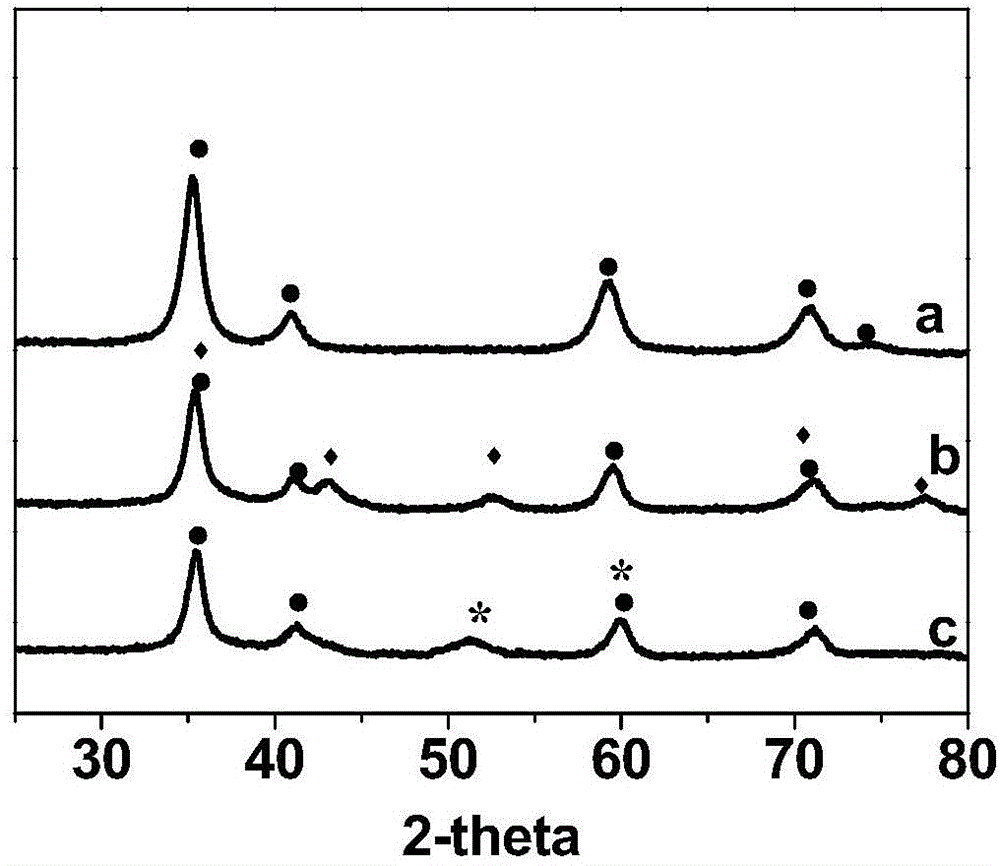

Image

Examples

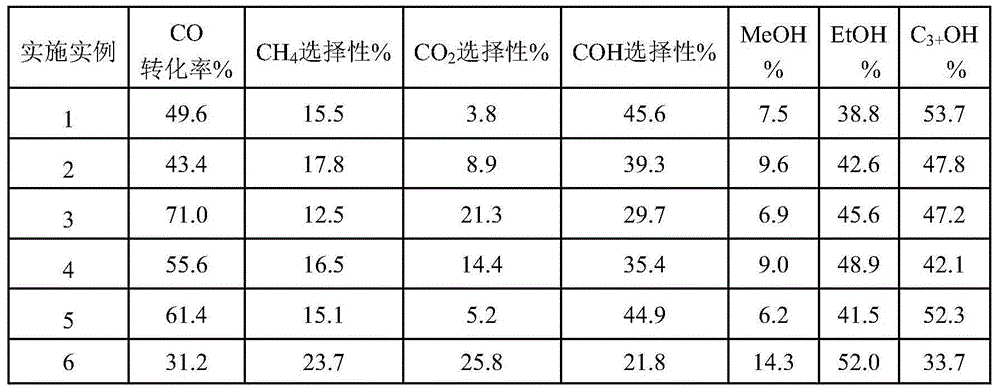

Embodiment 1

[0029] Disperse the hydrotalcite-like [patent application number: 2014107794454] containing Cu, Co and Al in water, mix it with the dispersion of zirconium hydroxide in water, stir at room temperature for 12 hours, and then put the solid obtained after suction filtration at a temperature of 80°C Drying at low temperature for 12 hours, the hydrotalcite-like precursor doped with zirconium hydroxide was obtained. The catalyst precursor was added to the muffle furnace, and the temperature was raised to 500 °C for 4 h at a heating rate of 5 °C / min to obtain Al 2 o 3 and ZrO 2 Mixed oxide doped copper cobalt mixed oxide. Among them, Cu is 11.9%, Co is 22.3%, Al 2 o 3 14.2%, ZrO 2 was 51.6%.

[0030] Take the roasted product into the reactor, and feed H into the reactor 2 The mixed gas of hydrogen and argon with a volume fraction of 5% was raised to 470° at a rate of 5°C / min for reduction for 3 hours, cooled naturally to room temperature, and passed through H 2 Syngas with a ...

Embodiment 2

[0033] Disperse the hydrotalcite-like stone containing Cu, Co, Mg and Al in water, mix it with the dispersion of cerium hydroxide in water, stir at room temperature for 6 hours, then filter with suction, and dry the obtained solid at 60°C for 24 hours to obtain Hydrotalcite-like precursors doped with cerium hydroxide. The catalyst precursor was added to the muffle furnace, and the temperature was raised to 600 °C for 6 h at a heating rate of 1 °C / min to obtain Al 2 o 3 and CeO 2 Mixed oxide supported copper cobalt oxide. Among them, Cu is 5.0%, Co is 14.0%, MgO is 25.0%, Al 2 o 3 16.0%, CeO 2 was 40.0%.

[0034] Take the roasted product into the reactor, and feed H into the reactor 2 The mixed gas of hydrogen and argon with a volume fraction of 5% was raised to 500° at a rate of 10°C / min for reduction for 1 hour, and then cooled naturally to room temperature and then passed into H 2 Syngas with a molar ratio of 2:1 to CO, raise the pressure to 4MPa, and set the volumet...

Embodiment 3

[0036] Disperse the hydrotalcite-like stone containing Cu, Co, Zn and Al in water, mix it with the dispersion of silicon hydroxide in water, stir at room temperature for 20 hours, then filter with suction, and dry the obtained solid at 120°C for 8 hours to obtain Hydrotalcite-like precursors doped with silicon hydroxide. Put the catalyst precursor into the muffle furnace, heat up to 300°C at a heating rate of 5°C / min and bake for 10h to obtain Al 2 o 3 and SiO 2 Copper cobalt oxide doped with mixed oxides. Among them, Cu is 25.0%, Co is 11.7%, ZnO is 15.8%, Al 2 o 3 20.0%, SiO 2 was 27.5%.

[0037] Take the roasted product into the reactor, and feed H into the reactor 2 The mixed gas of hydrogen and argon with a volume fraction of 5% was raised to 300° at a rate of 1°C / min for reduction for 3 hours, cooled naturally to room temperature, and passed through H 2 Syngas with a molar ratio of 2:1 to CO, raise the pressure to 6MPa, and set the volumetric space velocity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com