Hydrophilic surface-crosslinked ultra high molecular weight polyethylene moulding material and preparation method thereof

An ultra-high molecular weight, molding material technology, applied in the field of ultra-high molecular weight polyethylene materials, can solve the problems of lack of durability, unstable hydrophilic surface, high technical requirements for equipment, increase surface tension, facilitate industrial production, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

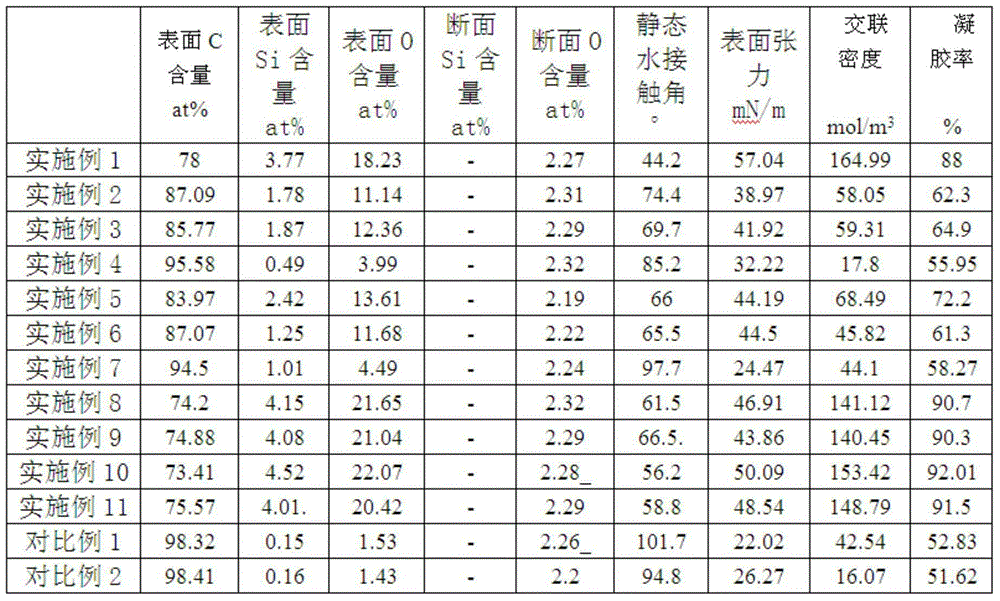

Examples

Embodiment 1

[0037] The preparation process steps of the hydrophilic surface cross-linked ultra-high molecular weight polyethylene molding material in this embodiment are as follows:

[0038] (1) Preparation of ultra-high molecular weight polyethylene molding materials

[0039] Using the compression molding method, the ultra-high molecular weight polyethylene powder is hot-pressed with a flat vulcanizer at 200 ° C and 10 MPa for 10 minutes, and then cold-pressed at room temperature and 10 MPa for 5 minutes to make a 1 mm thick sheet material. Cut the sheet-like ultra-high molecular weight polyethylene into 25mm×9mm samples, first clean the samples with deionized water ultrasonically for 3 times, each time for 10 minutes, then extract with acetone for 12 hours, and then vacuum-dry at 40°C to obtain ultra-high Molecular weight polyethylene molding material;

[0040] (2) Preparation of ultraviolet photoinitiator solution and vinyl silane solution

Embodiment 2

[0047] In this example, the composite solvent in step (2) is obtained by mixing absolute ethanol and n-hexane at a volume ratio of 21:9, and the initiator solution is a mixture of benzophenone and 2,4-dihydroxybenzophenone solution, wherein the mass concentration of benzophenone is 3%, and the mass concentration of 2,4-dihydroxybenzophenone is 2%.

[0048] In step (3), the two UV irradiation times were 10 minutes.

[0049] All the other processing conditions and operating method are identical with embodiment 1.

Embodiment 3

[0051] In the present embodiment, the composite solvent in step (2) is obtained by mixing absolute ethanol and n-hexane with a volume ratio of 21:49, and the initiator solution is a mixed solution of benzophenone and Michler's ketone, wherein benzophenone The mass concentration of is 3%, the mass concentration of Michler's ketone is 2%;

[0052] The energy density of ultraviolet light in two times of ultraviolet irradiation in step (3) is 400mJ / cm 2 , the irradiation time is 60 minutes;

[0053] All the other processing conditions and operating method are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com