Preparation method for polyene phosphatidyl choline for injection

A technology for polyene phosphatidylcholine and injection, applied in the direction of edible phospholipid composition, application, food science, etc., can solve the problems of long delivery cycle, difficult to guarantee content, less than 98%, and achieve production operation Convenience, reduced over-reliance, large processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

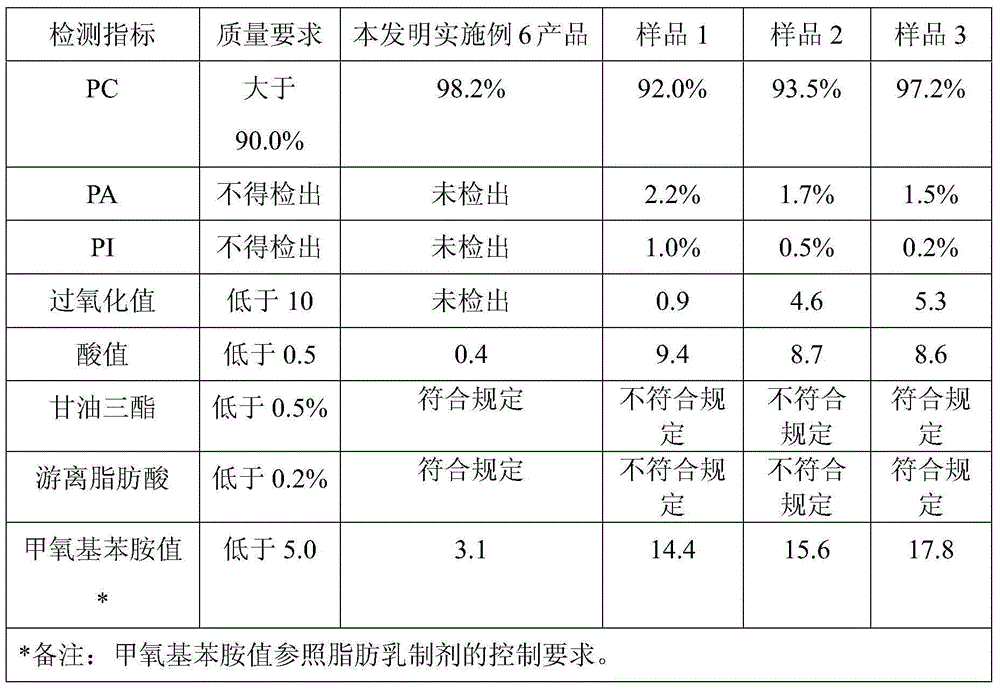

Examples

Embodiment 1

[0030] Get 1 kilogram of soybean lecithin, add chloroform-ethanol-water solution, dissolve and be made into raw material liquid, fill 8 kilograms of silica gels and carry out column chromatography, for the first time with eluent (chloroform 79.8%, ethanol 19.8%, water 0.4%) to elute 15 liters, and then elute 40 liters with eluent (dichloromethane 48.9%, ethanol 48.3%, water 2.8%) for the second time to collect the eluate, concentrate in vacuo, and freeze-dry to obtain polyene phospholipids Acylcholine product, PC transfer rate is 75.3%, phosphatidylcholine purity is 99.5%, lysophosphatidylcholine is not detected, phosphatidylinositol is not detected, phosphatidic acid is not detected, acid value is 0.3, over The oxidation value was not detected, the methoxyaniline value was 2.1, and the contents of triglyceride and free fatty acid all met the regulations.

Embodiment 2

[0032] Get 1 kilogram of soybean lecithin, add dichloroethane-isopropanol-water solution, dissolve and be made into raw material liquid, fill 7 kilograms of diol-based silica gels and carry out column chromatography, first time with eluent (dichloroethane 90.7 %, isopropanol 9.1%, water 0.2%) to elute 15 liters, then elute 40 liters of eluents (trichloromethane 62.3%, propanol 34.7, water 3.0%) for the second time to collect eluate, after Vacuum concentration, freeze-drying to obtain polyene phosphatidylcholine product, PC transfer rate is 81.2%, phosphatidylcholine purity is 99.0%, lysophosphatidylcholine is not detected, phosphatidylinositol is not detected, phosphatidic acid is not detected Detected, the acid value was 0.4, the peroxide value was not detected, the methoxyaniline value was 3.0, and the contents of triglyceride and free fatty acid all met the regulations.

Embodiment 3

[0034]Get 5 kilograms of soybean lecithin, add dichloromethane-ethanol-water solution, dissolve and be made into raw material liquid, fill 25 kilograms of silica gels and carry out column chromatography, use eluent (dichloromethane 89.8%, ethanol 10%, water for the first time) 0.2%) to elute 75 liters, and then elute 200 liters with eluent (chloroform 50.8%, n-butanol 46.7%, water 2.5%) for the second time to collect the eluate, concentrate in vacuo, freeze-dry to obtain poly Enene phosphatidylcholine product, PC transfer rate is 85.0%, phosphatidylcholine purity is 98.3%, lysophosphatidylcholine content is 0.2%, phosphatidylinositol is not detected, phosphatidic acid is not detected, acid value 0.4, the peroxide value was not detected, the methoxyaniline value was 4.2, and the contents of triglyceride and free fatty acid all met the regulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com