Method for preparing bioactive glass coating-coated magnesium alloy medical material by pressurized heat treatment

A bioactive glass and magnesium alloy technology, applied in coatings, metal material coating technology, medical science and other directions, can solve the problems of unsatisfactory adhesion strength of coatings/magnesium alloys, achieve a good physical barrier effect, improve biological Active, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 240 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0034] (2) Weigh 3.4mL of ethyl orthosilicate in 2.4mL of 0.1M HNO 3 In the medium, magnetically stirred for 30 minutes, then add 0.29 mL of triethyl phosphate, and continue to stir for 15 minutes. Weigh 1.38gNaNO 3 And 2.12gCa(NO 3 ) 2 ·4H 2 O was dissolved in 40 mL of deionized water. Ca(NO 3 ) 2 ,NaNO 3 The solution was slowly added dropwise to the above sol, magnetically stirred for 60 minutes to obtain a uniform and transparent (Na 2 O-CaO-SiO 2 -P 2 O 5 ) Sol, dilute the concentration of the glass sol to 2wt.% with deionized water. The polished and dried magnesium alloy is completely immersed in the prepared glass sol, immersed and pulled twice at a speed of 4 mm / min, and dried in the air for 24 hours.

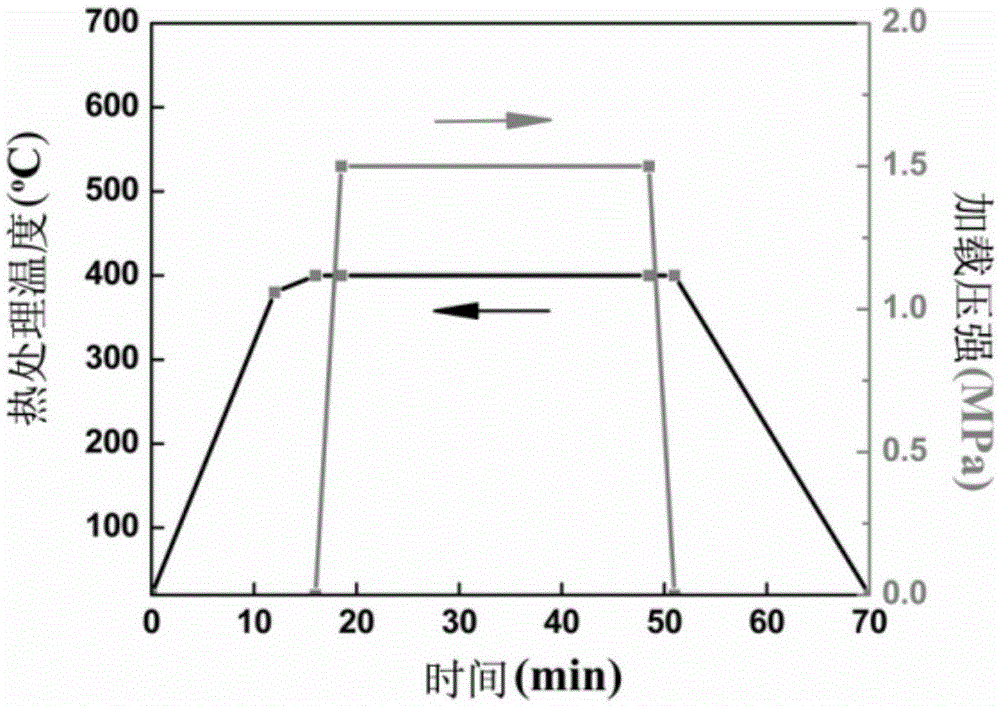

[0035] (3) Place the dried s...

Embodiment 2

[0039] (1) Process the AZ91 magnesium alloy into a block of 10mm×10mm×2mm, and use 240 # , 1200 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 6 minutes, and dried with hot air.

[0040] (2) F127 was added as a template when preparing glass sol, and then the concentration of glass sol was adjusted to 4wt.% with ethanol to obtain mesoporous (Na 2 O-CaO-SiO 2 -P 2 O 5 ) Sol, other processing procedures are the same as step 2 of Example 1.

[0041] (3) Place the dried sample in a muffle furnace, in an air atmosphere, increase from room temperature to 380°C at a rate of 2°C / min, keep it for 2h, and then cool with the furnace to remove the gel coating Organic matter and nitrate.

[0042] (4) Put the debinding sample into a closed jacket mold, place it in a hot isostatic pressing furnace, raise it from room temperature to 400°C at a rate of 15°C / min, and then load it at 10Pa / s Load the speed to 6MPa, then keep the temperature and ke...

Embodiment 3

[0045] (1) Use AZ61 as a magnesium alloy matrix, and 240 # , 1200 # , 1500 # The SiC sandpaper is polished, then ultrasonically cleaned in acetone, deionized water, and ethanol for 8 minutes, and dried with hot air.

[0046] (2) Weigh 1.669gP 2 O 5 Slowly add 22.5 mL of absolute ethanol and stir vigorously for 2 hours to obtain a uniform transparent phosphorus-based precursor solution. Weigh 10 mL of ethylene glycol and 15 mL of absolute ethanol solution, add 2.773 g of calcium nitrate, 0.256 g of sodium nitrate, and 0.14 g of zinc nitrate in sequence, and stir for 1 hour to obtain a transparent solution. The above solution was slowly added dropwise to the phosphorus-based precursor solution, stirred for 1 hour, added ammonia water to adjust its pH to 7-8, ultrasonically dispersed for 10 minutes to obtain uniform and transparent (CaO-P 2 O 5 -Na 2 O-ZnO) sol. The pre-polished magnesium alloy was completely immersed in the prepared glass sol, immersed and pulled 5 times at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com