Tussah silk protein adriamycin sustained release microsphere and preparation method thereof

A technology of tussah silk fibroin and slow-release microspheres, which is applied in the field of biomedicine, can solve the problems of large diameter of microspheres, influence on drug activity and albumin activity, low drug loading rate and embedding rate, and reduce toxic and side effects , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 80g tussah silk in the environment of 98~100℃, put it in the 2 CO 3 and 0.0625g / L sodium lauryl sulfate solution for degumming 3 times, 30min each time, bath ratio 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated lithium thiocyanate solution at a bath ratio of 1:10, and dissolve it for 60 minutes at 50°C±2°C. In the dialysis bag, dialyze with deionized water for 4 days, then centrifuge to obtain a regenerated tussah silk fibroin protein solution with a mass concentration of about 30 mg / ml, and put it in a refrigerator at 4°C for later use.

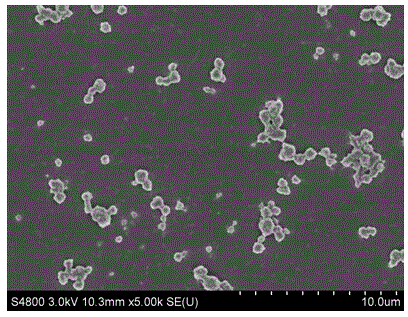

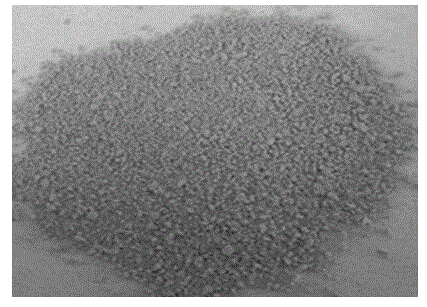

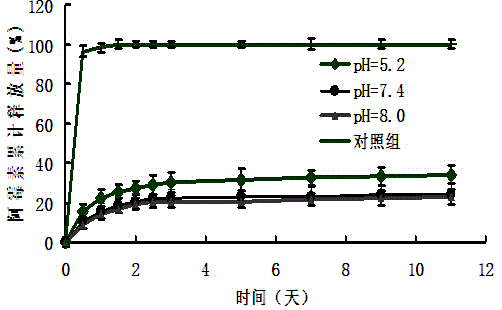

[0025] Adjust the concentration of tussah silk fibroin protein to 10 mg / ml, configure doxorubicin hydrochloride solution, the concentration is 10 mg / ml; configure calcium chloride solution, the concentration is 100 mmol per liter; add doxorubicin hydrochloride solution to tussah silk Stir mechanically in the protein solution to fully disperse doxor...

Embodiment 2

[0033] Put 120g of tussah silk in a stainless steel pot of 4L of deionized water, heat it to boiling with an induction cooker, add 0.06% Na 2 CO 3 In aqueous solution, degumming 3 times, 35min each time, bath ratio 1:60. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated lithium thiocyanate solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, and put the obtained tussah silk fibroin protein solution into a dialyzer with a molecular weight cut-off of 8-10 KDa bag, dialyzed with deionized water for 4 days, and then centrifuged to obtain a regenerated tussah silk fibroin protein solution with a mass concentration of about 25 mg / ml, and put it in a refrigerator at 4°C for later use.

[0034] Adjust the concentration of tussah silk fibroin protein to 20 mg / ml, configure doxorubicin hydrochloride solution, the concentration is 10 mg / ml; configure calcium nitrate solution, the concentration i...

Embodiment 3

[0036] Put 180 grams of tussah silk into 8L of 0.05% sodium carbonate aqueous solution, degumming at 98-100° C. for 0.5 hour, repeat the treatment 3 times, and obtain pure tussah silk fibroin fiber after fully washing. The tussah silk fibroin protein mixed solution is obtained by heating and dissolving the dried tussah silk fibers with 1 liter of lithium thiocyanate solution with a concentration of 9.3 mol / liter at 55±5° C. The cellulose membrane is used as a dialysis material, and the obtained tussah silk fibroin protein mixed solution is dialyzed with deionized water for 3 days to obtain a pure tussah silk fibroin protein solution.

[0037] Adjust the concentration of tussah silk fibroin protein to 30 mg / ml, configure doxorubicin hydrochloride solution, the concentration is 10 mg / ml; configure calcium gluconate solution, the concentration is 100 mmol per liter; add doxorubicin hydrochloride solution to tussah silk Mechanically stir in the protein solution to fully disperse d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com