Biodegradable lutein microspheres and manufacturing method thereof

A biodegradable and lutein technology, used in the fields of medicine, beverage and food, can solve the problems of limited solubility and high sensitivity, hinder the direct use of crude products, poor dyeing effect, etc., to improve the slow and controlled release treatment effect, improve Gastrointestinal side effects, improvement of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

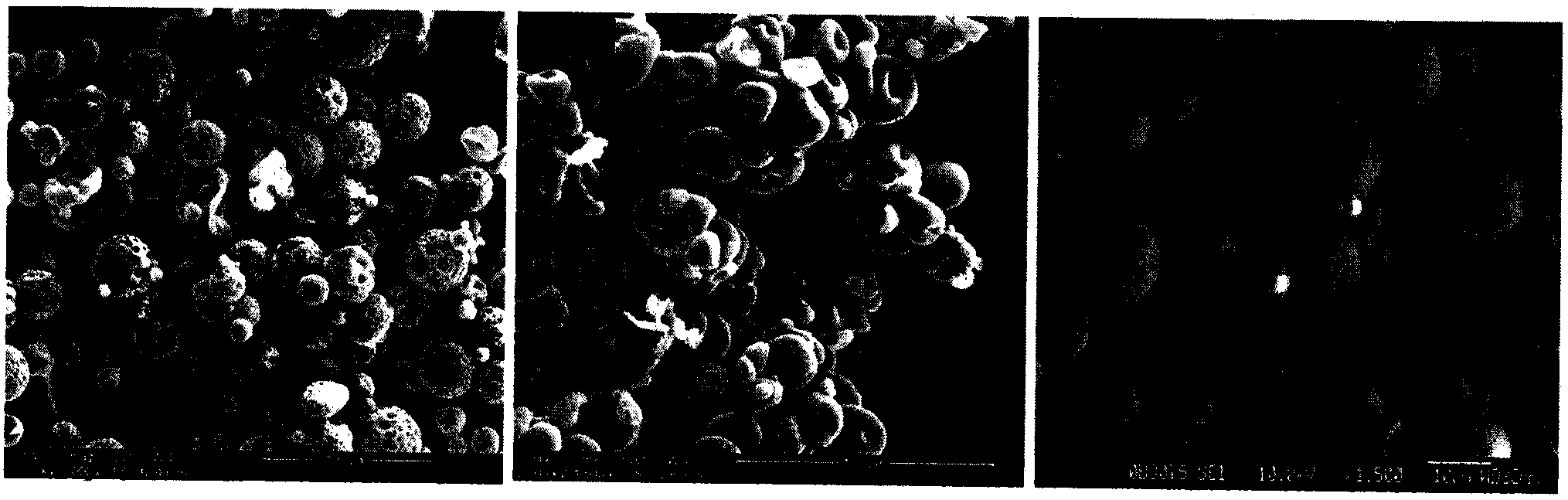

[0026] Different organic solvents of example 1 are used to prepare lutein PLGA microspheres

[0027] In this example, dimethyl carbonate (DMC), dichloromethane (DCM), and ethyl acetate (Et-Ac) were selected as organic solvents to prepare three groups of microsphere preparations. The formulations of the three groups of microsphere preparations are shown in Table 1. The formula of each microsphere preparation is 10wt% lutein and 90wt% polyester.

[0028] The type of solvent has a significant impact on the morphology of the product. In this example, lutein PLGA microspheres were prepared through different organic solvents. The preparation method using UPPS system is as follows:

[0029] (1) Weigh 0.1g lutein (1) and 0.9g ester-terminal PLGA (molecular weight is 40,000, LA / GA=50 / 50) in proportion;

[0030] (2) Put the PLGA (molecular weight is 40,000, LA / GA=50 / 50) at the end of the ester group in the step (1) into an organic solvent to completely dissolve to obtain a clear orga...

example 2

[0036] The preparation of the lutein microspheres of the PLGA of the different types of ester group end of example 2

[0037] This example prepares group 1: the lutein microsphere preparation of PLGA (molecular weight is 40,000, LA / GA=50 / 50) of ester group end, group 2: the PLGA of ester group end (molecular weight is 45,000, LA / GA=75 / 25 ) lutein microsphere preparation, the organic solvent used in this embodiment is a mixed solution of dichloromethane (DCM) and dimethyl carbonate (DMC), wherein the lutein microsphere formulation of group 1 is 32wt% lutein and 68wt% polyester Class, specifically PLGA (molecular weight is 40,000, LA / GA=50 / 50) of 0.45g lutein and 0.97g ester group terminal, and its preparation method is:

[0038] (1) Weigh 0.45g lutein and 0.97g ester-terminal PLGA (molecular weight is 40,000, LA / GA=50 / 50) in proportion;

[0039] (2) Put the PLGA (molecular weight is 40,000, LA / GA=50 / 50) in step (1) into dichloromethane (DCM) and dimethyl carbonate (volume rati...

example 3

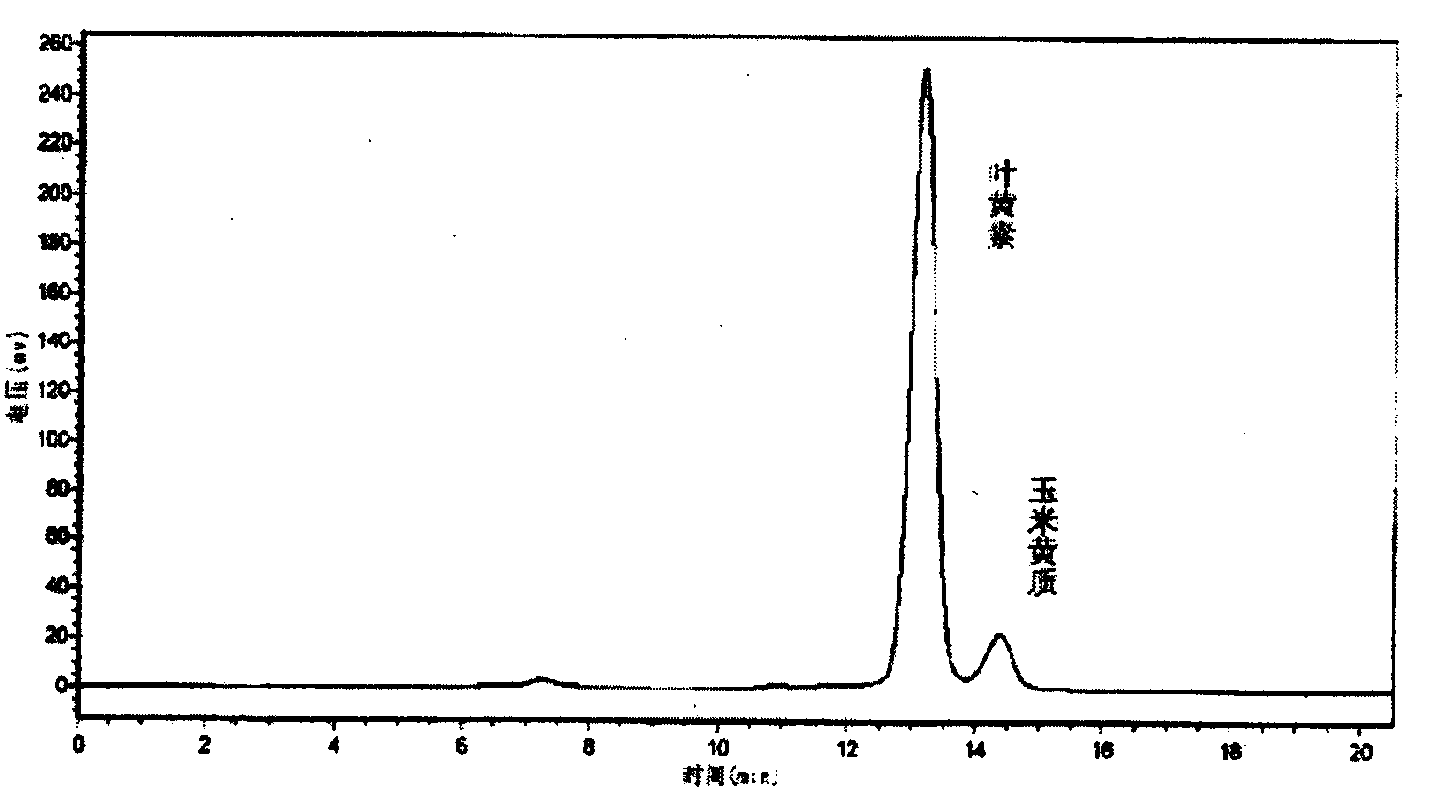

[0049] Mix 50g of lutein (content: 70% ± 5%) and 25g of microporous starch at room temperature, add 35g of maltodextrin, 6g of CMC-Na (carboxymethyl cellulose), 5g of sucrose, 0.1g of TBHQ, silk Mix the aqueous solution of 15g of plain protein colloid and stir evenly. The solution is supplied to the high-speed rotating disc of the droplet generating device through the peristaltic pump through the nozzle at an even speed. Micro-droplets are formed, the micro-droplets are in contact with the gas molecules in the gas field, the solvent volatilizes, the liquid-gas interface on the surface of the micro-droplets first solidifies, and then the internal solvent molecules gradually diffuse outward, and the polymer polymers precipitate inward until the micro-droplets are completely solidified The microspheres are obtained and the solidified microspheres settle and are collected in a sample collector or via a cyclone. Microspheres with an average particle size of 90 μm and a lutein conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com