Unsaturated hyperbranched polyurethane prepolymer as well as preparation method and application thereof

A hyperbranched polyurethane and unsaturated technology, which is applied in the field of LED light-curing 3D printing resin materials and its preparation, can solve the problems of energy saving and environmental protection that are not as good as LED lights, high viscosity, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of LED photocurable 3D printing material is as follows:

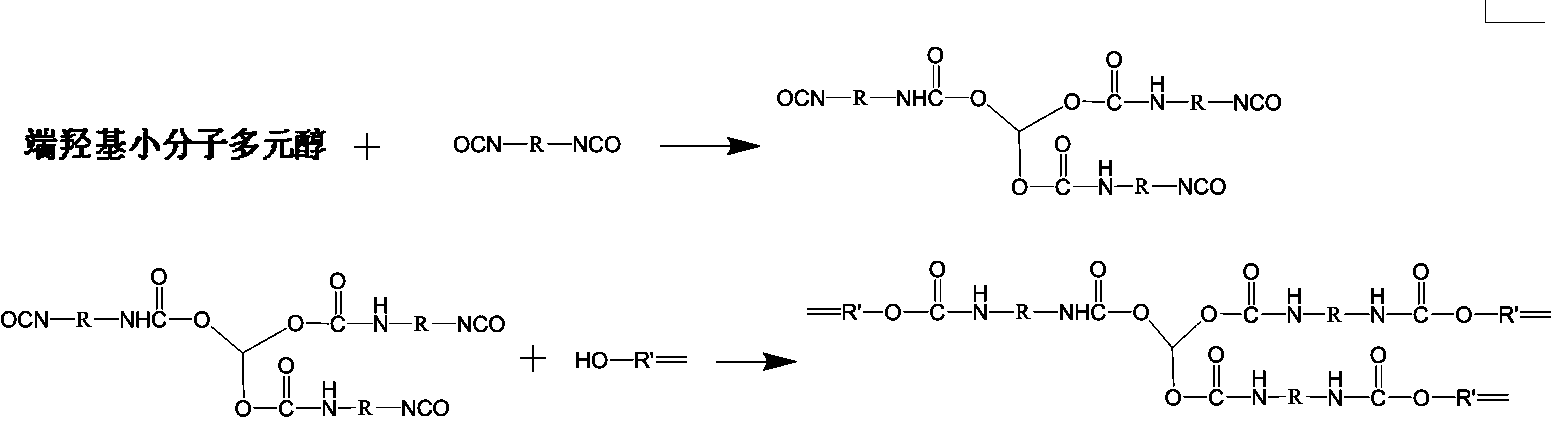

[0049] (1) Preparation of unsaturated hyperbranched polyurethane prepolymer A1: Mix 3-4g of hydroxyl-terminated small molecule polyol and 10-30g of diisocyanate and heat to 80°C for 2-4 hours. After the reaction, cool down to 40°C and add 2.5 -8g end-capping agent, heat up to 80°C for 3-5 hours, cool down to 50°C and discharge to obtain unsaturated hyperbranched polyurethane prepolymer A1. The molecular weight of unsaturated hyperbranched polyurethane prepolymer is controlled within 3000g / mol;

[0050] (2) Put unsaturated hyperbranched polyurethane prepolymer A1, acrylate oligomer, epoxy resin, reactive diluent, photoinitiator, photosensitizer, epoxy latent curing agent and auxiliary agent in yellow Mix evenly under the light environment and store in the dark, and keep the mixing temperature at 20-30°C.

[0051] The molecular weight of the hydroxyl-terminated small molecule polyol is less...

Embodiment 1

[0059] The unsaturated hyperbranched polyurethane prepolymer A1 structural formula used in this embodiment is as follows:

[0060] ,

[0061] where R is , from the raw material ; R' is , from the raw material .

[0062] The preparation process of LED light-cured 3D printing materials is as follows:

[0063] Mix 30g of trimethylolpropane and 120g of hexamethylene diisocyanate and heat to 80°C for 2 hours. After the reaction, cool down to 40°C, add 80g of hydroxyethyl acrylate, heat up to 80°C for 4 hours, and cool down to 60°C °C discharging to obtain unsaturated hyperbranched polyurethane prepolymer A1. Mix 30gA1, 30g polyester acrylate (Shanghai Chunan Trading Co., Ltd., product grade 6325-100), hydrogenated bisphenol A epoxy resin 10g (Yantai Oliver Chemical Co., Ltd., grade AL-3040), two Trimethylolpropane tetraacrylate (DTEMPTTA) 20g, α,α-dimethoxy-α-dimethoxyphenylacetophenone (DMPA) 2g, camphorquinone 1g, 2-chlorothioxanthone (CTX) 2g, N.N-dimethylaniline 2...

Embodiment 2

[0065] The unsaturated hyperbranched polyurethane prepolymer A1 structural formula used in this embodiment is as follows:

[0066] ,

[0067] where R is , from the raw material ; R' is , from the raw material .

[0068] The preparation process of LED light-cured 3D printing materials is as follows:

[0069]Mix 30g of glycerin and 149g of isophorone diisocyanate and heat it to 80°C for 3 hours. After the reaction, cool down to 40°C and add 90g of hydroxyethyl methacrylate, raise the temperature to 80°C for 5 hours, then cool down to 50°C. Material obtains unsaturated hyperbranched polyurethane prepolymer A1. Mix 40g of A1, 20g of polyurethane acrylate (Tianjin Heinz Technology Development Co., Ltd., product grade 5349), 5g of epoxy resin (Changzhou Zhengfa Chemical Raw Materials Co., Ltd., grade E44), 1,6-hexanediol bis Acrylates (HDDA) 5g, Tripropylene glycol diacrylate (TPGDA) 5g, Trimethylolpropane triacrylate (TMPTA) 10g, Benzoin 2g, 2-Phenyl-2,2-Dimethylamino-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com