Method for detecting phosphorus content in metallurgy raw materials

A technology of phosphorus content and raw materials, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the influence of chemical indicators, can solve the problems of cumbersome and time-consuming methods and low accuracy, and achieve thorough reduction The reduction speed is fast and the effect of reducing the experiment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

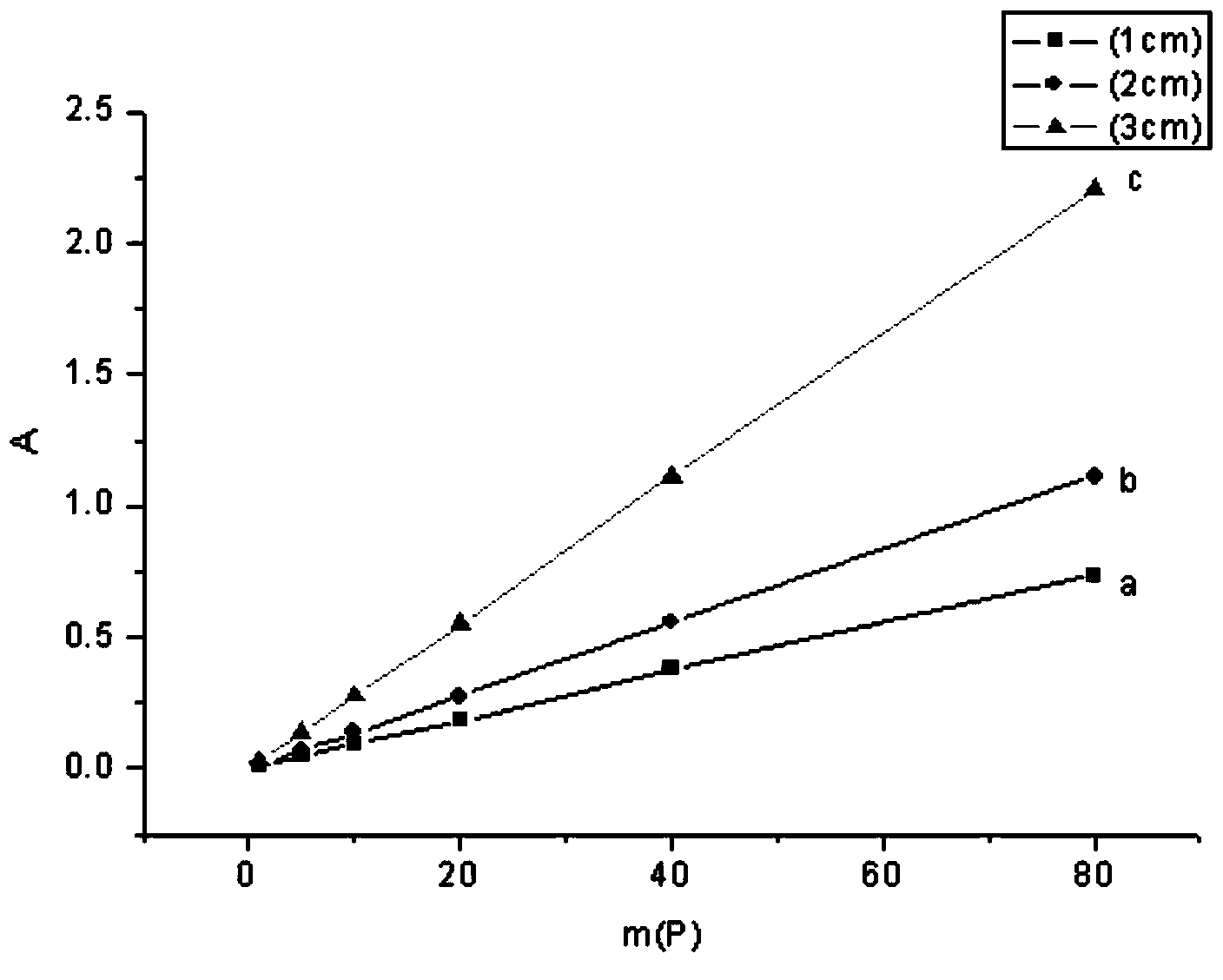

Image

Examples

Embodiment 1

[0054] 1) The magnetite concentrate standard sample GBW07221 produced by Wuhan Iron and Steel Research Institute was used as the sample.

[0055] 2) Weigh 0.5000g of magnetite concentrate standard sample, put it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add 20mL of concentrated hydrochloric acid, cover with a watch glass, heat at low temperature for 30min, then add 5mL of concentrated hydrofluoric acid , 5mL of concentrated nitric acid, continue to heat for 30min, add 5mL of concentrated perchloric acid, heat at low temperature until perchloric acid fumes, continue to heat and fumes to form wet salt. Cool, add 10mL of hydrochloric acid with a concentration of 10% by volume, rinse the wall of the cup with a small amount of water, heat on the electric hob to dissolve the salt, remove the beaker from the electric hob, cool to room temperature, and dilute the test solution to 100mL. The test solution was dry-filtered with medium-speed filt...

Embodiment 2

[0060] 1) The sinter standard sample GBW07219a produced by Wuhan Iron and Steel Research Institute was used as the sample.

[0061] 2) Weigh 0.2000g of sinter standard sample GBW07219a, place it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add 25mL concentrated hydrochloric acid, cover it with a watch glass, heat at low temperature for 30min, then add 5mL concentrated hydrofluoric acid , 5mL of concentrated nitric acid, continue to heat for 30min, add 5mL of concentrated perchloric acid, heat at low temperature until perchloric acid fumes, continue to heat and fumes to form wet salt. Cool, add 10mL of hydrochloric acid with a concentration of 10% by volume, rinse the cup wall with a small amount of water, heat on an electric hob to dissolve salts, remove the beaker from the electric hob, cool to room temperature, and dilute the test solution to 100mL. The test solution was dry-filtered with medium-speed filter paper.

[0062] 3) Dispense...

Embodiment 3

[0066] 1) The dolomite standard sample 0247 produced by Wuhan Iron and Steel Research Institute was used as the sample.

[0067] 2) Weigh 1.0000g of dolomite standard sample 0247, put it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add 20mL of concentrated hydrochloric acid, cover with a watch glass, heat at low temperature for 30min, then add 5mL of concentrated hydrofluoric acid , 5mL of concentrated nitric acid, continue to heat for 30min, add 5mL of concentrated perchloric acid, heat at low temperature until perchloric acid fumes, continue to heat and fumes to form wet salt. Cool, add 10mL of hydrochloric acid with a concentration of 10% by volume, rinse the cup wall with a small amount of water, heat on an electric hob to dissolve salts, remove the beaker from the electric hob, cool to room temperature, and dilute the test solution to 100mL. The test solution was dry-filtered with medium-speed filter paper.

[0068] 3) Dispense 20.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com