Inorganic metal oxide semiconductor film of perovskite structure and metallic oxide thin film transistor

A technology of oxide semiconductor and perovskite structure, which is applied in the direction of transistors, semiconductor devices, electrical components, etc., can solve the problems that the back channel etching structure cannot be used, the metal source and drain electrodes cannot be etched, and the production cost is reduced. , to achieve the effect of high current switch ratio, strong acid resistance, and low sub-threshold swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A metal oxide thin film transistor is provided with a gate, an active layer, an insulating layer between the gate and the active layer, a source and a drain electrically connected to both ends of the active layer, and a passivation layer, The active layer is an inorganic metal oxide semiconductor film with a perovskite structure, and the active layer covers the insulating layer.

[0042] It should be noted that the upper and lower positional relationship in the present invention is a reference positional relationship with the substrate as the lower layer.

[0043] It should be noted that the metal oxide thin film transistor of the present invention may be a structure including only a substrate, a gate, an insulating layer, an active layer, a source electrode and a drain electrode, and a passivation layer, and may further include an etch stop layer Or pixel definition layer, etc., and can also be integrated with other devices and other structures.

[0044] Specifically, ...

Embodiment 2

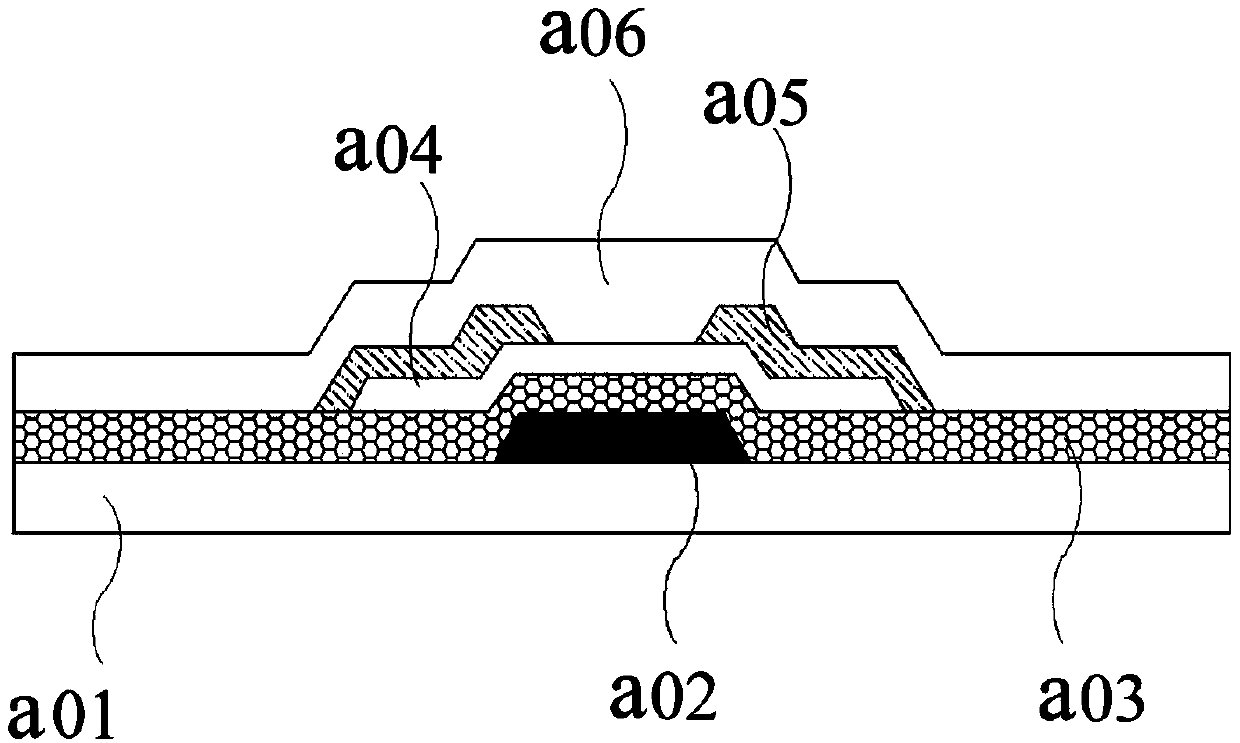

[0055] A metal oxide thin film transistor, such as figure 1 As shown, the thin film transistor has a back channel etching structure, and is provided with a substrate a01, a gate a02, an insulating layer a03, an active layer a014, a source-drain electrode a05, and a passivation layer a06.

[0056] The gate a02 is located on the substrate a01, the insulating layer a02 is located on the substrate and the gate, the active layer a02 covers the upper surface of the insulating layer and corresponds to the gate, the source and the drain are spaced from each other and connected to the active layer respectively. The electrodes at both ends of the source layer are connected, and the passivation layer a06 covers the upper surface of the exposed surfaces of the active layer, the source electrode and the drain electrode.

[0057] The substrate a01 may be a glass substrate, a metal substrate, or a polymer substrate. The substrate has a buffer layer and a water and oxygen barrier layer. Whe...

Embodiment 3

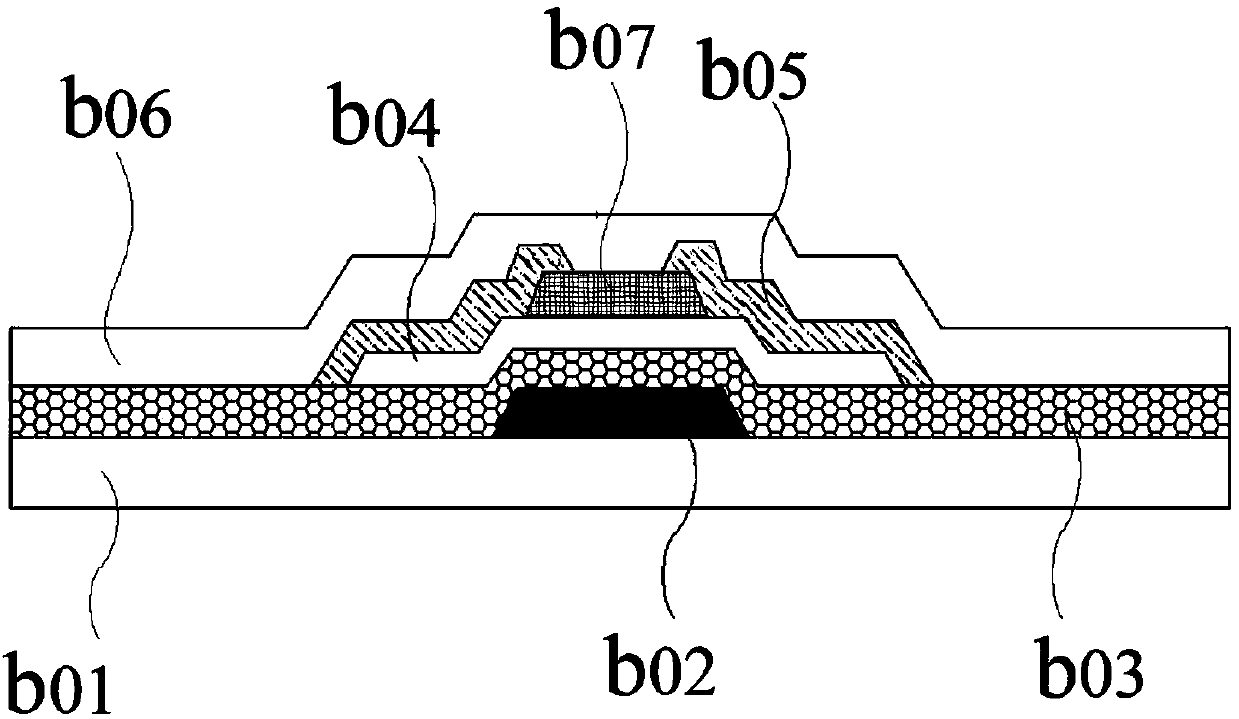

[0077] A metal oxide thin film transistor, such as figure 2 As shown, the thin film transistor has an etch stop structure, and is provided with a substrate b071, a gate b02, an insulating layer b03, an active layer b04, a source-drain electrode b05, and a passivation layer b06, and the active layer covers the insulating layer. The thin film transistor is also provided with an etch stop layer b07. The etch stop layer b07 is SiO x 、SiN x o y 、SiN x , SiC, Al 2 o 3 or ZrO2 Thin films with a thickness of 100 nm to 200 nm.

[0078] The structures and preparation methods of the substrate b071 , the gate b02 , the insulating layer b03 , the active layer b04 , the source-drain electrodes b05 , and the passivation layer b06 are the same as those in Embodiment 2, and will not be repeated here.

[0079] The metal oxide thin film transistor of the present invention adopts an inorganic metal oxide semiconductor thin film with a nanocrystalline perovskite structure as an active laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com