Method for synthesizing hydrophilic ZSM-5 zeolite molecular sieve membrane

A technology of zeolite molecular sieve membrane and ZSM-5, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of long synthesis time, easy temperature gradient, influence, etc., and achieve shortened synthesis time and good Separation performance, effect of high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare the hydrophilic ZSM-5 molecular sieve membrane as follows:

[0037] (1) Treatment of porous carrier tube: the porous carrier used in the synthesis of ZSM-5 molecular sieve membrane is α-Al 2 o 3 The carrier tube has an average pore diameter of 2-3 μm and a porosity of 30%-40%. α-Al 2 o 3 Before coating the crystal, the carrier tube was polished to a smooth surface with sandpaper, then ultrasonically cleaned with deionized water, and finally dried overnight in an oven at 80°C for future use.

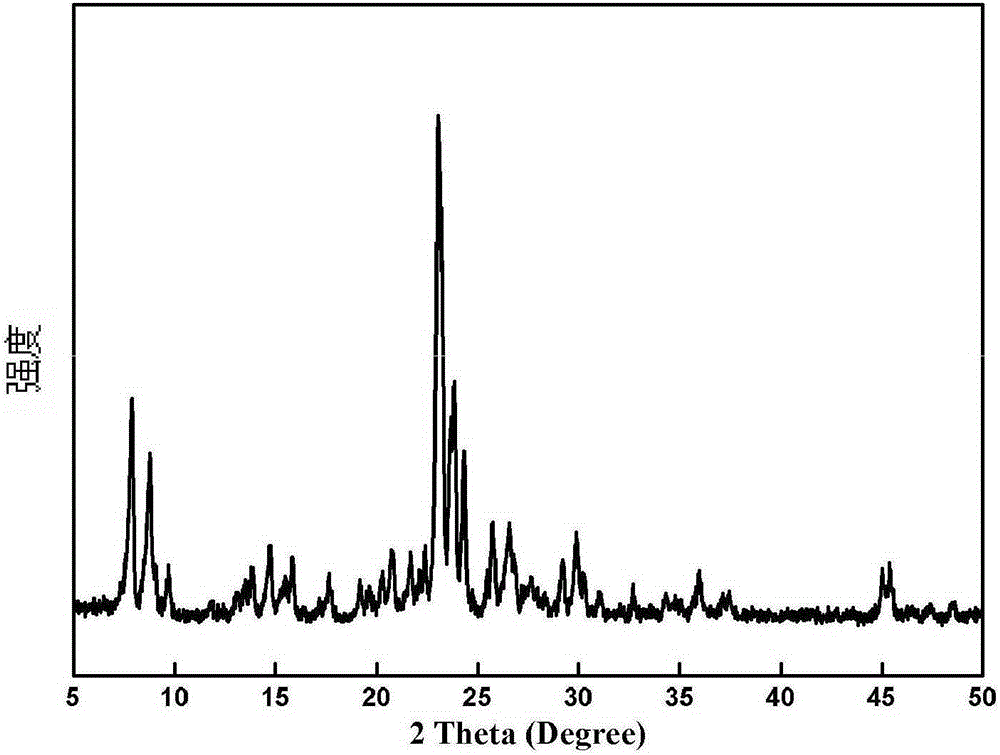

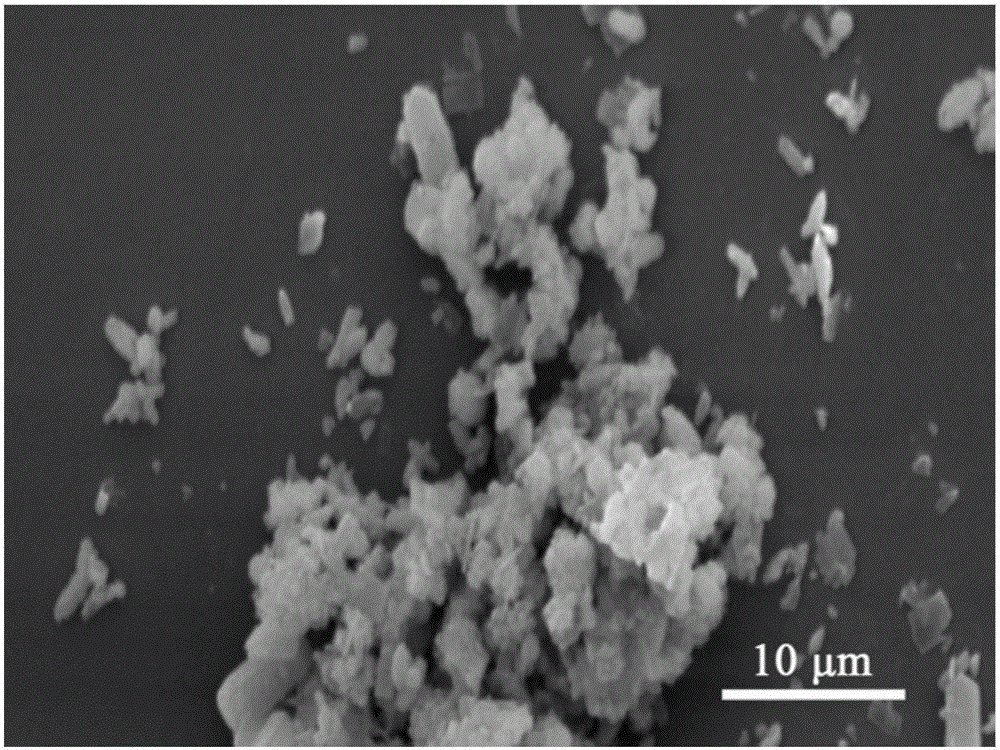

[0038] (2) Preparation of ZSM-5 seed liquid: get 0.5gZSM-5 zeolite molecular sieve (Shanghai Zhuoyue Chemical Technology Co., Ltd., SiO 2 / Al 2 o 3 =15~45) Add 100g of deionized water, use a magnetic stirrer to stir and disperse the solution evenly, and place it in an ultrasonic wave to vibrate at intervals during the process, prepare a ZSM-5 seed liquid with a mass fraction of 0.5wt%, and mix the seed liquid After ultrasonic stirring for 0.5h, it was used for later ...

Embodiment 2

[0048] By the same operation of Example 1, only the mol ratio of each component in the synthetic liquid is:

[0049] NaOH: Al source: Si source: H 2 O:NaF=0.4:0.08:1:120:0.8, the synthesized ZSM-5 zeolite molecular sieve membrane also has good pervaporation separation performance. For 90wt.% acetic acid dehydration and 90wt.% isopropanol dehydration, the permeation flux is 0.6kg / m 2 h and 3.1kg / m 2 h, the separation factors were 1200 and 3100, respectively.

Embodiment 3

[0051] By the same operation of Example 1, only the mol ratio of each component in the synthetic liquid is:

[0052] NaOH: Al source: Si source: H 2 O:NaF=0.8:0.5:3:300:1.8, the pervaporation separation performance of the synthesized ZSM-5 zeolite molecular sieve membrane is better than that of Example 2. For dehydration of 90wt.% acetic acid and 90wt.% isopropanol respectively, the permeation flux is 0.7kg / m 2 h and 3.5kg / m 2 h, the separation factors were 1700 and 4300, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com