Busbar connection type high-performance IGBT (insulated gate bipolar transistor) module and manufacturing method thereof

A production method and high-performance technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of insufficient reliability of devices, insufficient surge current capability and overload capacity of IGBT devices , Chips and connection wires are not in sufficient contact, etc., to shorten the production and processing cycle, improve switch performance, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

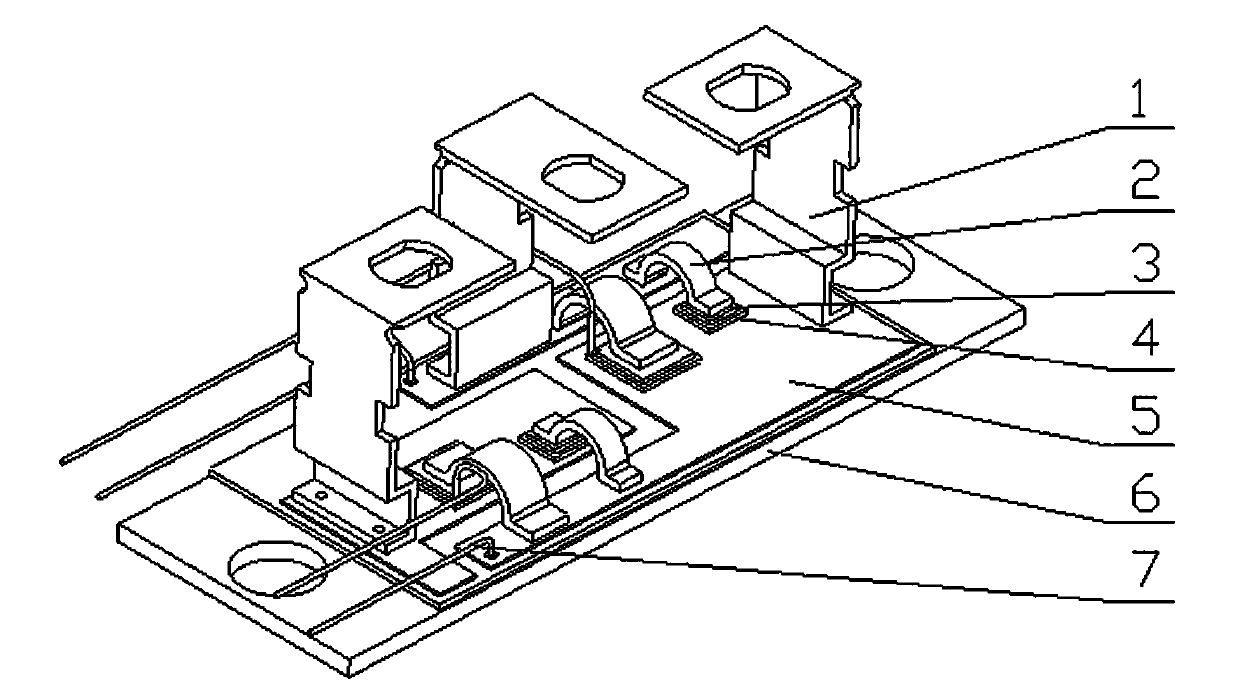

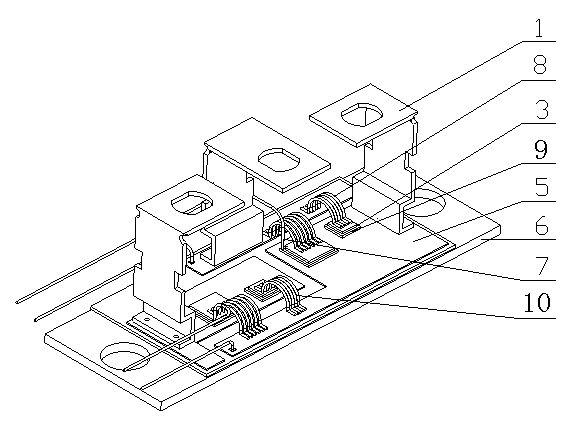

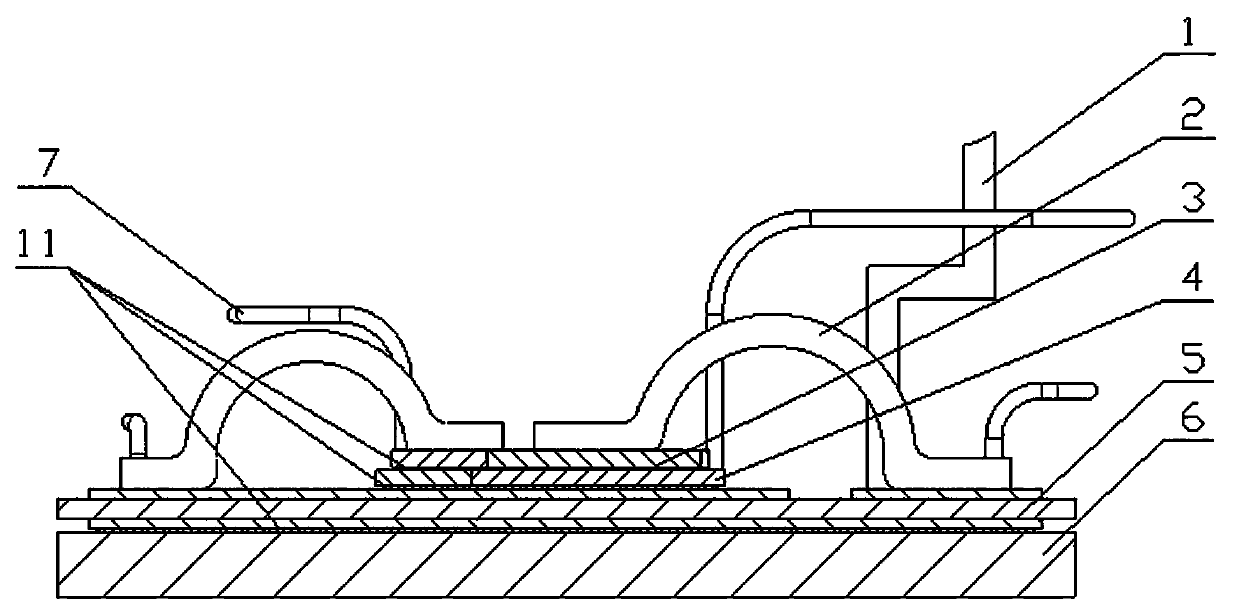

[0031] The following takes the two-unit IGBT module as an example to introduce the busbar-connected high-performance IGBT module and its manufacturing method:

[0032] The two-unit bus-connected high-performance IGBT module includes a housing 13, a bottom plate 6, a DBC plate 5, an electrode 1, a semiconductor chip 4, a gate between the module gate and the IGBT chip gate, and the auxiliary source and the chip source. Lead 7 and busbar 2. There are three electrodes 1, which are respectively fixed on one (or several mutually separated) DBC boards 5 . One (or more) DBC boards 5 are all welded on the bottom plate 6, which is the same as the prior art. The semiconductor chip 4 is an IGBT chip and is welded on the DBC board 5 . The semiconductor chip can also be a rectifier chip, a thyristor chip or other semiconductor chips. The busbar 2 is made of copper or copper alloy, and its basic shape is a strip with good toughness, which is bent according to the space and the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com