A reversible repair functional matrix resin for pultrusion and preparation method thereof

A technology of pultrusion and matrix resin, which is applied in the field of reversible repair functional matrix resin and its preparation, can solve problems such as damage, matrix cracking, and broken materials, and achieve the effect of wide application range and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

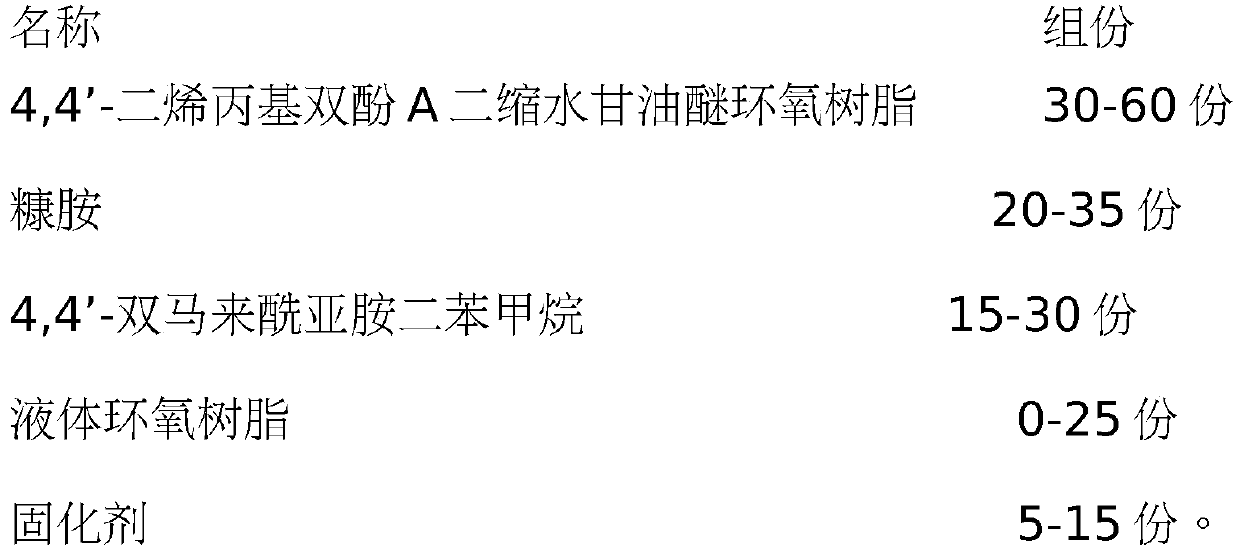

Method used

Image

Examples

Embodiment 1

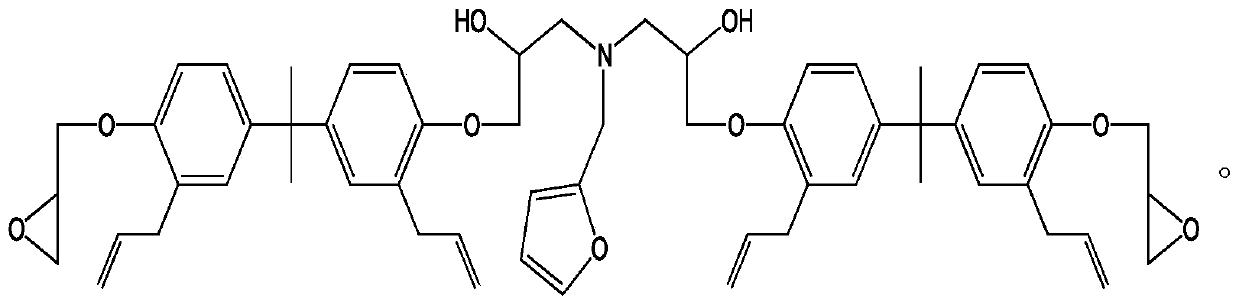

[0025] Add 23g of 4,4'-o-diallyl bisphenol A and 46g of epichlorohydrin into a 250mL four-neck flask equipped with a mechanical stirrer, a thermometer, a reflux condenser, a numerically controlled sampling pump, and a nitrogen gas introduction device, and slowly increase The temperature of the oil bath is 60°C. After the 4,4'-o-diallyl bisphenol A is completely dissolved, slowly add 64g of NaOH solution (30wt%) with a numerical control injection pump, and the injection is completed within 1 hour. The reaction temperature is controlled Continue to react at 60°C for 4 hours. After the reaction is completed, cool and filter to remove the generated sodium chloride, distill under reduced pressure to remove unreacted epichlorohydrin, dissolve it in toluene again, wash with deionized water three times, and remove the solvent , to obtain a light yellow viscous liquid product, 4,4'-diallyl bisphenol A diglycidyl ether epoxy resin. Dissolve 30 g of the above-mentioned light yellow visco...

Embodiment 2

[0028] Add 95g of 4,4'-o-diallyl bisphenol A and 184g of epichlorohydrin into a 1000mL four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a nitrogen introduction device, and slowly raise the temperature of the oil bath to 65 °C, after 4,4'-o-diallyl bisphenol A is completely dissolved, put 80g of NaOH solid into the flask, control the reaction temperature at 60 °C, and react for 4 hours. After the reaction is completed, cool and filter to remove the generated sodium chloride. Unreacted epichlorohydrin was removed by pressure distillation, dissolved in toluene again, washed with deionized water three times, and the solvent was removed to obtain a light yellow viscous liquid product, 4,4'-diallyl bisphenol A Diglycidyl ether epoxy resin. Dissolve 150 g of the above-mentioned light yellow viscous liquid product in 220 g of toluene and place it in a 1000 mL four-necked flask equipped with mechanical stirring, a thermometer, a reflux condens...

Embodiment 3

[0031] Add 95g of 4,4'-o-diallyl bisphenol A and 184g of epichlorohydrin into a 1000mL four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a nitrogen introduction device, and slowly raise the temperature of the oil bath to 65 °C, after 4,4'-o-diallyl bisphenol A is completely dissolved, put 80g of NaOH solid into the flask, control the reaction temperature at 60 °C, and react for 4 hours. Unreacted epichlorohydrin was removed by pressure distillation, dissolved in toluene again, washed with deionized water three times, and the solvent was removed to obtain a light yellow viscous liquid product, 4,4'-diallyl bisphenol A Diglycidyl ether epoxy resin. Dissolve 150 g of the above-mentioned light yellow viscous liquid product in 220 g of toluene and place it in a 1000 mL four-neck flask equipped with a mechanical stirrer, a thermometer, a reflux condenser, a numerical control sampling pump and a nitrogen introduction device, and the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com