A large-size aluminum-steel reaction-assisted thermal toughening friction welding method

A friction welding, large-scale technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low strength of welded joints and large joint stress, improve the welding interface, reduce the stress of welding joints, and improve welding Effect of quality and weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

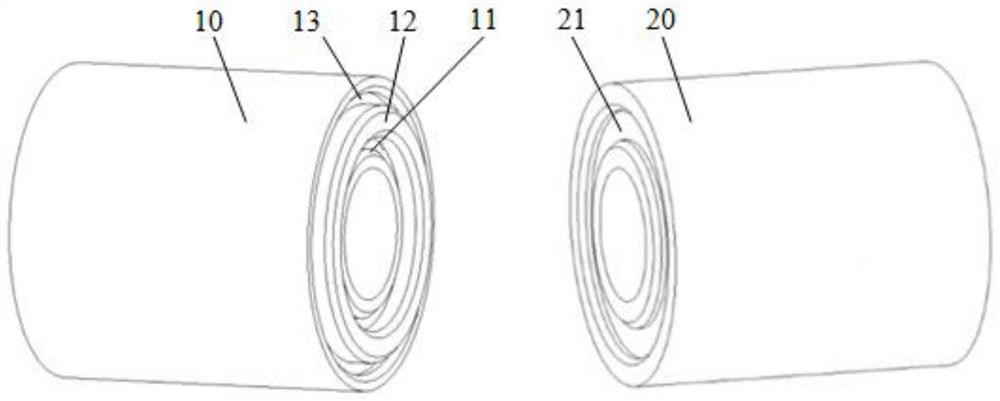

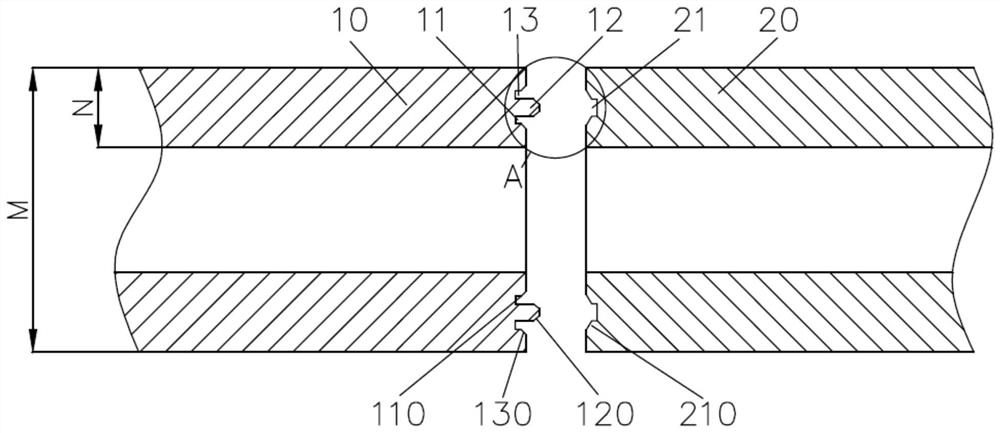

[0036] A large-scale aluminum-steel reaction heat-assisted frictional welding method, characterized in that: it includes the two-way fitting structure design of the welded joint of the aluminum member 20 and the steel member 10 and setting a welding auxiliary layer at the welded joint; the aluminum member 20 and the steel member 10 are welded with a pipe fitting structure, and the diameter and thickness of the aluminum member 20 and the steel member 10 are consistent, and the diameter of the steel member 10 is 450 mm, and the wall thickness is 120 mm.

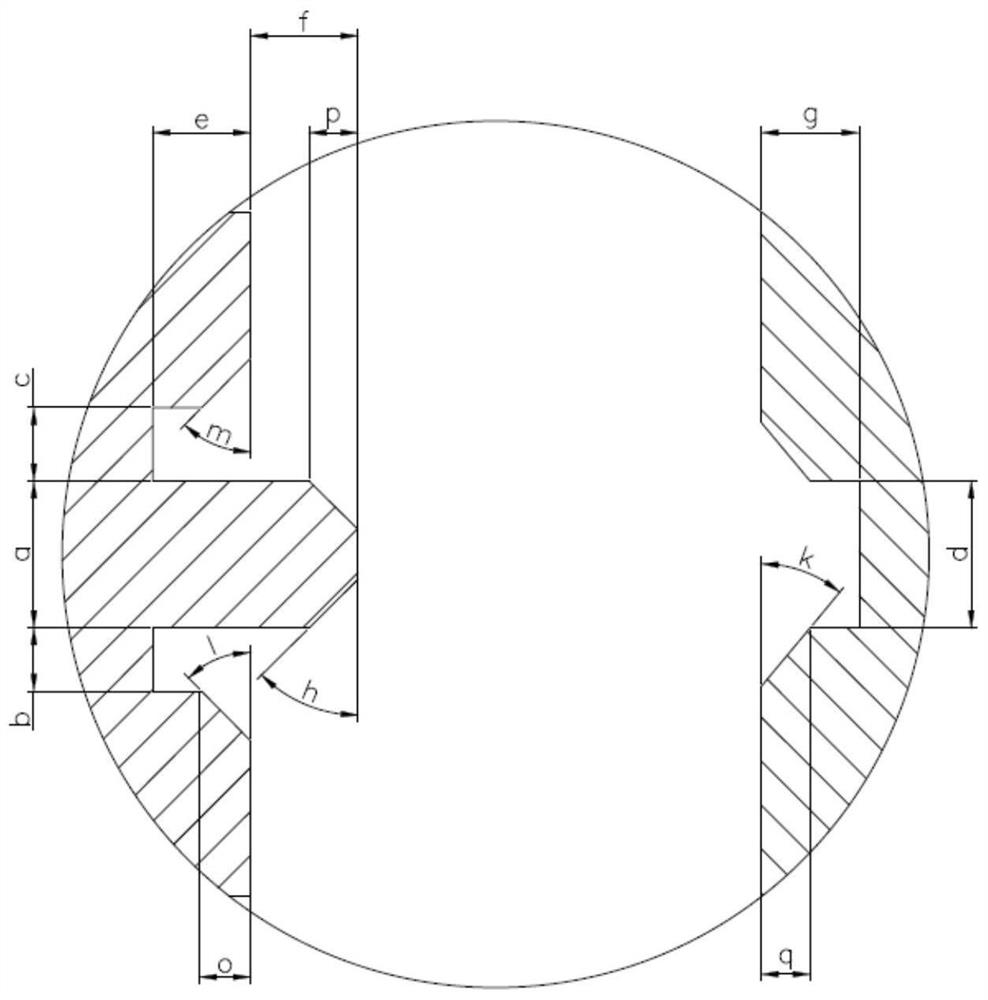

[0037] The two-way fitting structure design for the welded joint of the aluminum member 20 and the steel member 10 is specifically: for the surface to be welded of the steel member 10, an annular steel inner groove 11 and an annular steel boss 12 are sequentially processed outward from the central axis. And the annular steel outer groove 13, the steel inner groove 11 and the steel outer groove 13 are close to the steel boss 12 a...

Embodiment 2

[0048] A large-scale aluminum-steel reaction heat-assisted frictional welding method, characterized in that: it includes the two-way fitting structure design of the welded joint of the aluminum member 20 and the steel member 10 and setting a welding auxiliary layer at the welded joint; the aluminum member 20 and the steel member 10 are welded with a pipe fitting structure, and the diameter and thickness of the aluminum member 20 and the steel member 10 are consistent, and the diameter of the steel member 10 is 500 mm, and the wall thickness is 140 mm.

[0049] The two-way fitting structure design for the welded joint of the aluminum member 20 and the steel member 10 is specifically: for the surface to be welded of the steel member 10, an annular steel inner groove 11 and an annular steel boss 12 are sequentially processed outward from the central axis. And the annular steel outer groove 13, the steel inner groove 11 and the steel outer groove 13 are close to the steel boss 12 a...

Embodiment 3

[0060] A large-scale aluminum-steel reaction heat-assisted frictional welding method, characterized in that: it includes the two-way fitting structure design of the welded joint of the aluminum member 20 and the steel member 10 and setting a welding auxiliary layer at the welded joint; the aluminum member 20 and the steel member 10 are welded with a pipe fitting structure, and the diameter and thickness of the aluminum member 20 and the steel member 10 are consistent, and the diameter of the steel member 10 is 550 mm, and the wall thickness is 160 mm.

[0061] The two-way fitting structure design for the welded joint of the aluminum member 20 and the steel member 10 is specifically: for the surface to be welded of the steel member 10, an annular steel inner groove 11 and an annular steel boss 12 are sequentially processed outward from the central axis. And the annular steel outer groove 13, the steel inner groove 11 and the steel outer groove 13 are close to the steel boss 12 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com