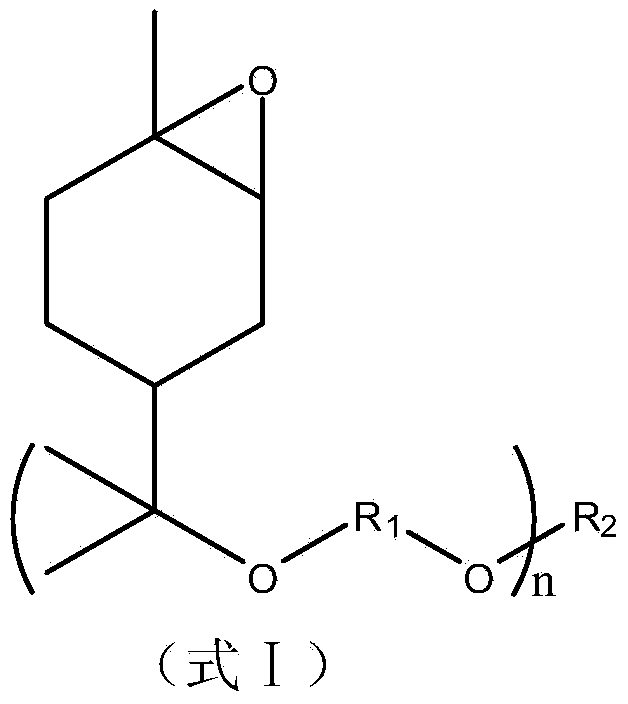

Alicyclic epoxy compounds, preparing method thereof and applications of the compounds

A cycloaliphatic epoxy compound technology, which is applied in the field of compound preparation, can solve the problems of lack of chemical resistance, corrosion of microcircuits, poor application of mechanical properties and processing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

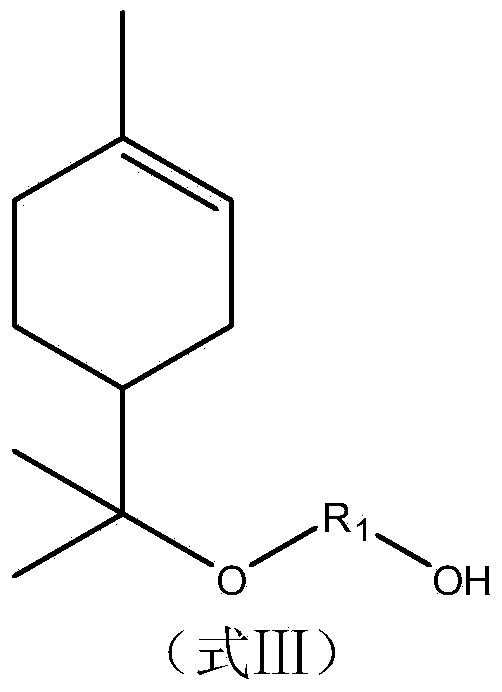

[0075] When the starting materials for the reaction are limonene and aliphatic diols, the preparation method of the alicyclic epoxy compound is as follows:

[0076] (1) Add 10mmol of limonene, 11mmol of 1,4-butanediol and 2.0mmol of ferric chloride to 45mL of chloroform solvent cooled in an ice bath, magnetically stir for 60 minutes, and then raise the temperature to 25°C, pass a developing agent (from petroleum Ether: ethyl acetate is composed of 3:1 by volume) TLC monitors the progress of the reaction until the raw material disappears or no longer decreases on the TLC plate. Water is added to terminate the reaction, the aqueous layer is extracted with dichloromethane, the organic layers are combined, and the pressure is reduced. The solvent is distilled off; the product is purified by column chromatography (the eluent is petroleum ether: ethyl acetate in a volume ratio of 3:1).

[0077] The obtained product was detected by nuclear magnetic resonance, and the data obtained are as ...

Embodiment 2

[0090] When the starting materials for the reaction are limonene and aliphatic diols, the preparation method of the alicyclic epoxy compound is as follows:

[0091] (1) Add 10mmol of limonene, 13mmol of 1,3-propanediol and 2.5mmol of ferric chloride to 50mL of acetonitrile solvent cooled in an ice bath, the resulting mixture was stirred magnetically for 30 minutes and then heated to 35°C, passed through a developing agent (from petroleum Ether: ethyl acetate is composed of 3:1 by volume) TLC monitors the reaction process. When the raw materials disappear or no longer decrease on the TLC plate, the reaction is terminated by adding water, the water layer is extracted with dichloromethane, the organic layers are combined, and the vacuum distillation is performed The solvent is removed; the product is purified by column chromatography (the eluent is petroleum ether: ethyl acetate in a volume ratio of 5:1).

[0092] The obtained product was detected by nuclear magnetic resonance, and th...

Embodiment 3

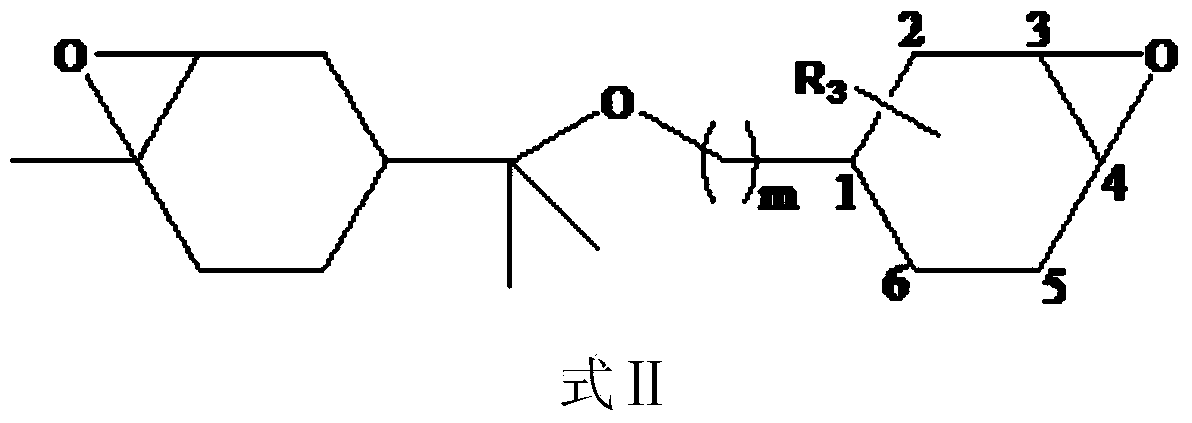

[0105] When the reaction starting materials are limonene and alicyclic olefin monoalcohol, the preparation method of the alicyclic epoxy compound is as follows:

[0106] (1) Add 10mmol of limonene, 10mmol of cyclohexenyl alcohol and 2.0mmol of anhydrous ferric trichloride to 45mL of dichloromethane solvent cooled in an ice bath, magnetically stirred for 40 minutes and then heated to 45°C. It is composed of petroleum ether: ethyl acetate in a volume ratio of 4:1) TLC monitors the reaction process until the raw material disappears on the TLC plate or no longer decreases by adding water to terminate the reaction. After extracting the aqueous layer with dichloromethane, the organic layers are combined, and The residual solvent in the organic layer is distilled off under reduced pressure, and the obtained crude product is purified by column chromatography eluent (petroleum ether: ethyl acetate in a volume ratio of 3:1);

[0107] The obtained product was detected by nuclear magnetic reso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com