Liquid crystal polyester resin composition

A resin composition, liquid crystal polyester technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of insufficient, low warpage, strength, toughness, etc., achieve good low, excellent bending fatigue properties, good warp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] Hereinafter, the present invention will be further described in detail through examples, but the gist of the present invention is not limited only to the following examples.

[0110] (A) Liquid crystal polyester resin

[0111] The compositional analysis and property evaluation of the liquid crystal polyester resin were performed by the following methods.

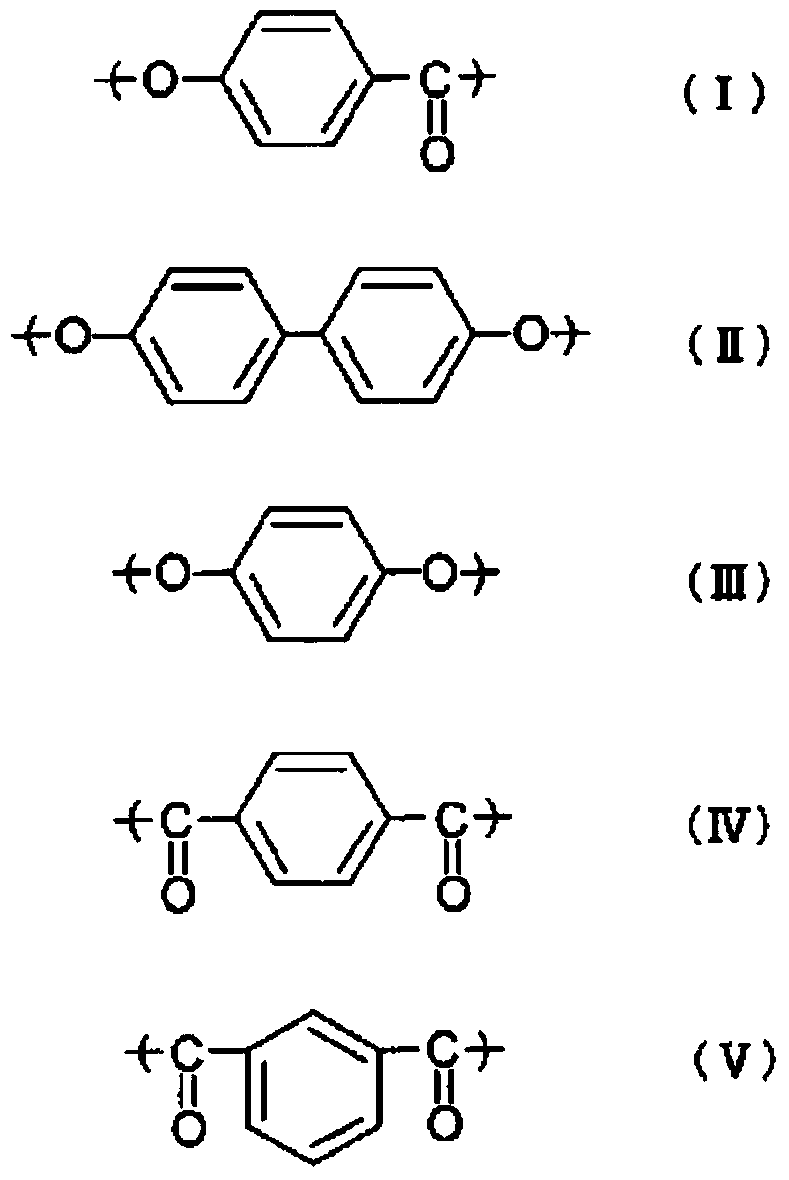

[0112] (1) Composition analysis of liquid crystal polyester resin

[0113] Composition analysis of liquid crystal polyester by 1 H-NMR spectrum ( 1 H-NMR) measurement to implement. Weigh 50 mg of liquid crystal polyester resin into an NMR sample tube and dissolve in a solvent (pentafluorophenol / 1,1,2,2-tetrachloroethane-d 2 =65 / 35 (weight ratio) mixed solvent) 800 μL, using a UNITY INOVA500 NMR apparatus (manufactured by Barian Corporation), at an observation frequency of 500 MHz and a temperature of 80° C. 1 The H-NMR measurement consists of an analysis of the peak area ratio derived from each structural unit ob...

manufacture example 1

[0137] 932 parts by weight of p-hydroxybenzoic acid, 251 parts by weight of 4,4'-dihydroxybiphenyl, 99 parts by weight of hydroquinone, and 284 parts by weight of terephthalic acid were added to a 5 L reaction vessel equipped with a stirring blade and a distillation pipe. , 90 parts by weight of isophthalic acid and 1,252 parts by weight of acetic anhydride (1.09 equivalents of the total phenolic hydroxyl group), reacted at 145° C. for 1 hour while stirring under a nitrogen atmosphere, and then made the jacket temperature at an average temperature increase rate of 0.68° C. From 145°C to 270°C per minute, and from 270°C to 350°C at an average temperature increase rate of 1.4°C / min. The heating time is 4 hours. Then, the polymerization temperature was kept at 350° C., the pressure was reduced to 1.0 mmHg (133 Pa) over 1.0 hour, and then the reaction was continued, and the polymerization was completed after the torque required for stirring reached 20 kg·cm. Next, pressurize the ...

manufacture example 2

[0141] 907 parts by weight of p-hydroxybenzoic acid, 294 parts by weight of 4,4'-dihydroxybiphenyl, 94 parts by weight of hydroquinone, and 343 parts by weight of terephthalic acid were added to a 5 L reaction vessel equipped with a stirring blade and a distillation pipe. , 61 parts by weight of isophthalic acid and 1272 parts by weight of acetic anhydride (1.09 equivalents of the total phenolic hydroxyl group), and reacted at 145° C. for 1 hour while stirring under a nitrogen atmosphere, and then the jacket temperature was increased at an average temperature increase rate of 0.63° C. From 145°C to 270°C per minute, and from 270°C to 335°C at an average temperature increase rate of 1.6°C / min. The heating time is 4 hours. Then, the polymerization temperature was kept at 335° C., the pressure was reduced to 1.0 mmHg (133 Pa) over 1.0 hour, and then the reaction was continued, and the polymerization was completed after the torque required for stirring reached 20 kg·cm. Next, pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com