Method for producing a component carrier, component carrier and semi-finished product

A component-carrying, electronic component technology, applied in printed circuit manufacturing, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., which can solve problems such as high risk of yield drop, dissipation, and thermal management problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

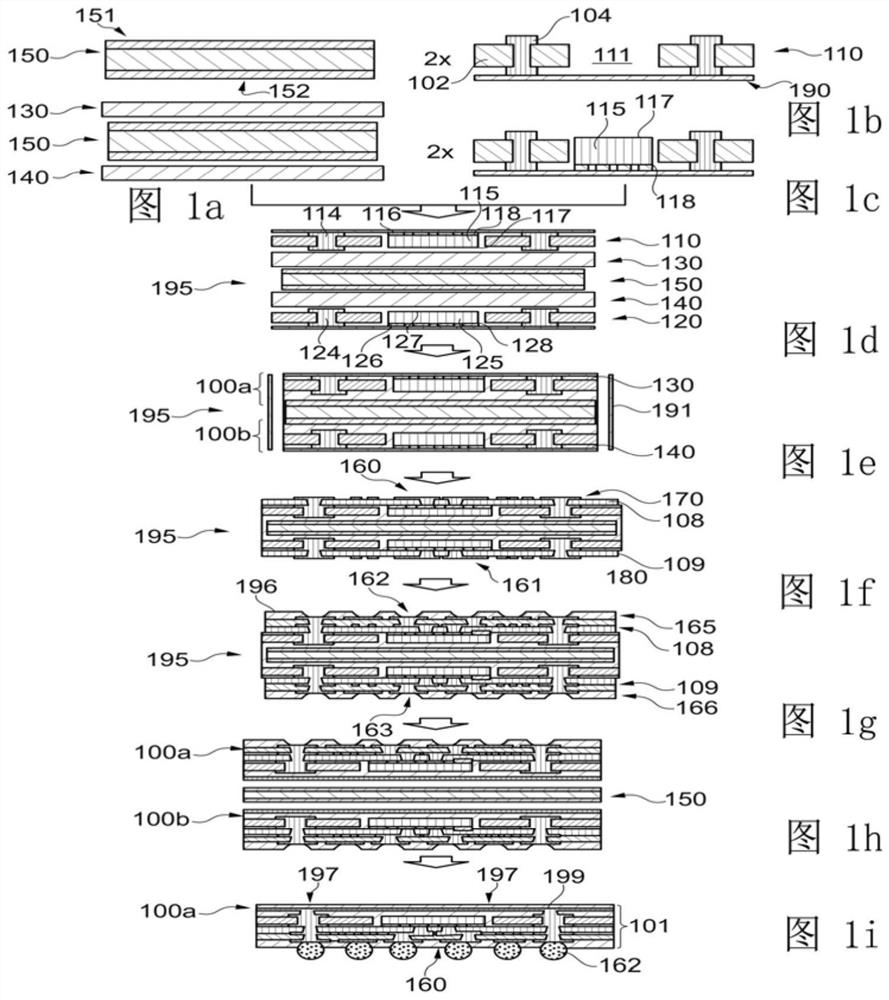

[0079] Fanned out wafer level packaging (FOWLP) is one of the latest packaging trends in microelectronics, according to an exemplary embodiment of the present invention. It has high potential for significant package miniaturization in relation to package volume and its thickness. The core of FOWLP technology is the formation of reconfigured molded wafers bonded to thin film redistribution layers to produce SMD compatible packages. The main advantages of FOWLP are substrateless packages, low thermal resistance, improved RF performance due to shorter interconnects and direct IC connections through thin film metallization instead of wire bonds or flip-chip bumps, and lower parasitics. Especially compared to the FC-BGA package, the inductance of FOWLP is much lower. In addition, the redistribution layer can also provide embedded passive devices and antenna structures using a multilayer structure. It can be used for system-in-package (SiP) and heterogeneously integrated multi-chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com