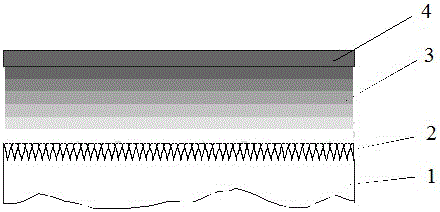

A nanocomposite tool coating with gradient composition design and its preparation method

A component design, nanocomposite technology, applied in coatings, nanotechnology, layered products, etc., can solve problems such as the inability to meet the requirements of better performance of tools, and achieve huge market potential and use value, mechanical wear resistance and The effect of improving the high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

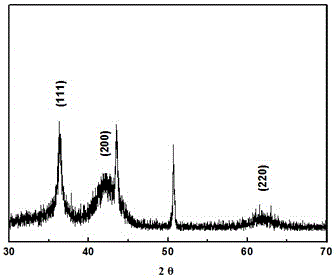

Method used

Image

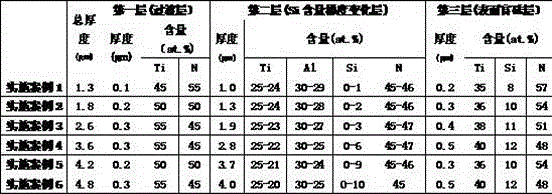

Examples

Embodiment example

[0026]

[0027] The cutting tool substrate pretreatment process in Example 3 is as follows: the uncoated carbide end mill is ultrasonically cleaned with a metal cleaning solution, rinsed with deionized water, and dried with dry and clean compressed air.

[0028] The coating steps are as follows: fix the pretreated uncoated carbide end milling cutter evenly on the bracket with a distance greater than or equal to 10mm, put it into the ion coating machine, adjust the rotation speed of the workpiece bracket to 5rpm, and pump it to the background Vacuum 2.5×10 -3 Pa, turn on the heater at the same time, raise the temperature to 500°C; open the Ar gas flow valve, adjust the vacuum chamber to about 0.6Pa, apply a negative bias voltage of 1000V to the substrate, and perform glow sputtering cleaning for 20min; then reduce the negative bias voltage of the substrate to 100V, Turn on the pure Ti target, adjust the target current to 100A, and bombard the substrate with high-energy Ti io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com