A method and device for calcium treatment of molten steel by injecting calcium steam

A calcium vapor and calcium treatment technology is applied in the field of calcium treatment of molten steel by spraying calcium steam, which can solve the problems of deteriorating calcium treatment effect, increasing treatment cost, splashing, etc. The effect of high processing efficiency and strong operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

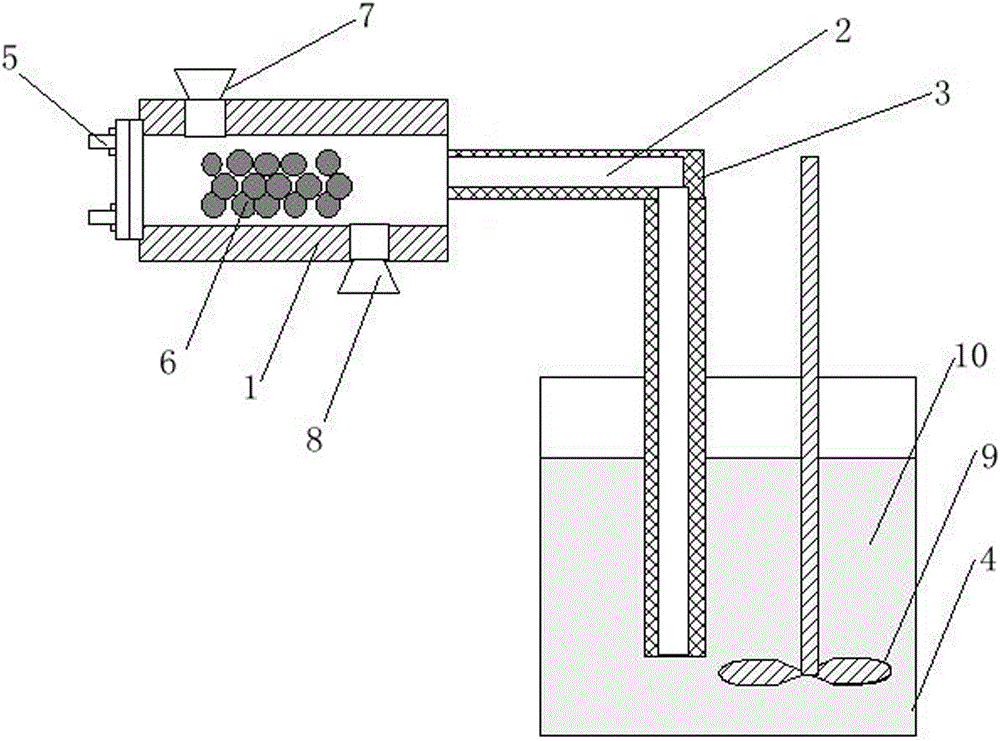

[0037] Injecting calcium steam of the present invention carries out calcium treatment method to molten steel, carries out according to the following steps:

[0038] (1) Preparation of high temperature calcium vapor:

[0039] Calcining marble to obtain quicklime, mixing quicklime and Al reducing agent according to the mass ratio of CaO:Al=100:75, and then pressing it into pellets under the pressure of 20MPa, putting the prepared pellets into the high temperature outside the ladle In the furnace, it is heated to 1500°C to generate high-temperature calcium vapor;

[0040] (2) High temperature calcium vapor transportation:

[0041] One end of the high-temperature furnace that generates high-temperature calcium vapor is airtightly connected to the spray gun through a high-temperature delivery pipeline. The spray gun is inserted into the molten steel pool of the ladle, and the other end of the high-temperature furnace tube is sealed with a flange. An inlet pipe is installed on the ...

Embodiment 2

[0046] Injecting calcium steam of the present invention carries out calcium treatment method to molten steel, carries out according to the following steps:

[0047] (1) Preparation of high temperature calcium vapor:

[0048] Calcining marble to obtain quicklime, mixing quicklime and Al reducing agent according to the mass ratio of CaO:Al=100:70, and then pressing it into pellets under a pressure of 50MPa, and putting the prepared pellets into the high temperature outside the ladle In the furnace, it is heated to 1350°C to generate high-temperature calcium vapor;

[0049] (2) High temperature calcium vapor transportation:

[0050] One end of the high-temperature furnace that generates high-temperature calcium vapor is airtightly connected to the spray gun through a high-temperature delivery pipeline. The spray gun is inserted into the molten steel pool of the ladle, and the other end of the high-temperature furnace tube is sealed with a flange. The gas pipe leads into the hig...

Embodiment 3

[0055] Injecting calcium steam of the present invention carries out calcium treatment method to molten steel, carries out according to the following steps:

[0056] (1) Preparation of high temperature calcium vapor:

[0057] Calcining marble to obtain quicklime, mixing quicklime and Al reducing agent according to the mass ratio of CaO:Al=100:60, and then pressing it into pellets under a pressure of 100MPa, putting the prepared pellets into the high temperature outside the ladle In the furnace, it is heated to 1600°C to generate high-temperature calcium vapor;

[0058] (2) High temperature calcium vapor transportation:

[0059] One end of the high-temperature furnace that generates high-temperature calcium vapor is airtightly connected to the spray gun through a high-temperature delivery pipeline. The spray gun is inserted into the molten steel pool of the ladle, and the other end of the high-temperature furnace tube is sealed with a flange. The gas pipe leads into the high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com