A kind of pc/pmma alloy and preparation method thereof

A technology of alloy and graft copolymer, which is applied in the field of PC/PMMA alloy and its preparation, can solve the problems of incompatibility between surface hardness and toughness, insufficient processing fluidity, poor resistance to stress cracking, etc., to improve the environment of the blending workshop, Improve the mechanical properties and stability, the effect of stable alloy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the synthesis of St / MAH-g-MMA graft copolymer (grafting thing 1)

[0035] 1) Synthesis of PMMA with a thioester bond at the end:

[0036] The synthesis method is a conventional method, wherein the molar ratio of AIBN: cyanoisopropyl dithiobenzoate: methyl methacrylate is 1:5:200, the solvent is DMF, the reaction temperature is 60°C, and the reaction time is 24h, wherein Methyl methacrylate is 2mol, and the end is a thioester bond PMMA;

[0037] 2) Synthesis of PMMA with mercapto groups at the end:

[0038] In the above reaction system, add 2mmol of dimethylphenylphosphine and n-hexylamine respectively (the ratio of dimethylphenylphosphine and n-hexylamine is 1:2), react at room temperature for 1h, and obtain PMMA with a mercapto group at the end;

[0039] 3) Synthesis of PMMA macromonomer

[0040] Continue to add 0.05mol allyl methacrylate in the above reaction system, and react at room temperature for 4h to obtain PMMA macromonomer;

[0041] 4) Synthe...

Embodiment 2

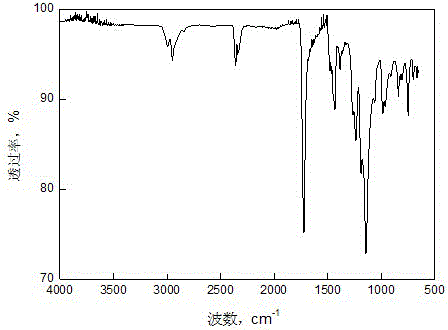

[0044] Embodiment 2: the preparation of grafting object 2

[0045]The synthesis steps are the same as in Example 1, wherein the molar ratio of AIBN: 2,2'-[methylthiobis(thio)]bis[2-methylpropionic acid]:methyl methacrylate is 1:5:300 Add 2mmol of dimethylphenylphosphine and n-hexylamine (the ratio of dimethylphenylphosphine and n-hexylamine is 1:2), 0.6mmol of AIBN, to obtain St / MAH-g-PMMA, graft 2, its molecular weight is 100000, of which m, n, l are 10, 20, 50 respectively, and its structure is as follows figure 2 As shown, among them, the wave number is 1650-1450cm -1 It is the stretching vibration peak of benzene ring, 1730cm -1 It is the carbonyl stretching vibration peak on MMA and maleic anhydride.

Embodiment 3

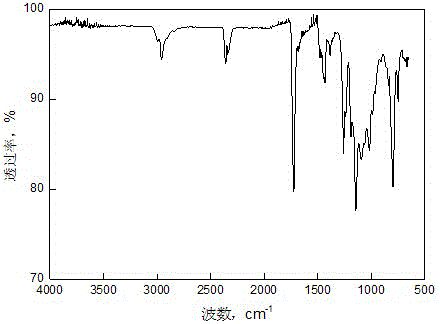

[0046] Embodiment 3: the preparation of grafting thing 3

[0047] The synthesis steps are the same as in Example 1, wherein AIBN: 4-cyano-4-(thiobenzoyl) valeric acid: the molar ratio of methyl methacrylate is 1:5:300 to obtain St / MAH-g-PMMA , that is, grafting material 3, its molecular weight is 40000, wherein m, n, l are 1, 20, 20 respectively, and its structure is as follows image 3 As shown, among them, the wave number is 1650-1450cm -1 It is the stretching vibration peak of benzene ring, 1730cm -1 It is the carbonyl stretching vibration peak on MMA and maleic anhydride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com