A kind of determination method of total iron content in vanadium slag

A determination method and technology for iron content, applied in the field of chemical detection, can solve the problems of incomplete dissolution of the sample, interference with the total iron content, large measurement error, etc., and achieve the effect of good promotion and application prospects, fast analysis speed, and reduction of test errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] ——Determination of total iron content in vanadium slag samples

[0042] Reagents for detection:

[0043] Sodium Hydroxide: (solid).

[0044] Sulfuric acid: the concentration is (ρ1.84g / mL).

[0045]Phosphoric acid: the concentration is (ρ1.69g / mL).

[0046] Hydrochloric acid: the concentration is (ρ1.19g / mL).

[0047] Titanium trichloride: the concentration is (150g / L-200g / L).

[0048] Sodium hydroxide solution: the concentration is 50g / L.

[0049] Hydrochloric acid: (1+1).

[0050] Hydrochloric acid: (5+95).

[0051] Ammonium thiocyanate solution: the concentration is 50g / L.

[0052] Stannous chloride solution 100g / L: Weigh 10g of stannous chloride and dissolve it in 20mL of hot hydrochloric acid (ρ1.19g / mL), dilute to 100mL with water, and shake well.

[0053] Sodium tungstate solution 250g / L: Weigh 25g of sodium tungstate and dissolve it in 95mL of water (if it is cloudy, filter it), add 5mL of phosphoric acid (4.2), and shake well.

[0054] Titanium trichlo...

Embodiment 2

[0076] ——Determination of total iron content in vanadium slag samples

[0077] Detection reagent: same as embodiment 1

[0078] Sample testing:

[0079] A. Sample pretreatment: crush the sample to a particle size of ≤0.125mm, dry it at 105-110°C for 1.5-2.5h, seal it in a desiccator, and cool it to 20-25°C.

[0080] B, C, D, E, F steps are the same as embodiment 1.

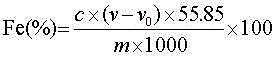

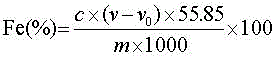

[0081] G. Calculation of content: The calculation of iron content in the sample is as follows:

[0082] c - the concentration of potassium dichromate standard titration solution is 0.0400 (mol / L);

[0083] m - the mass of the sample in step B is 0.2000g;

[0084] V 0 - The volume of the standard titration solution of potassium dichromate consumed by the blank test solution for titration is 0.00ml;

[0085] V——The titration sample solution consumes a volume of potassium dichromate standard titration solution of 34.50ml;

[0086] 55.85 - the mass per mole of iron, in grams per mole (g / mol).

[0087]

[00...

Embodiment 3

[0091] ——Determination of total iron content in vanadium slag samples

[0092] Detection reagent: same as embodiment 1

[0093] Sample testing:

[0094] A. Sample pretreatment: crush the sample to a particle size of ≤0.125mm, dry it at 105-110°C for 1.5-2.5h, seal it in a desiccator, and cool it to 20-25°C.

[0095] B, C, D, E, F steps are the same as embodiment 1.

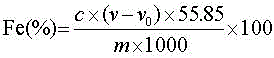

[0096] G. Calculation of content: The calculation of iron content in the sample is as follows:

[0097] c - the concentration of potassium dichromate standard titration solution is 0.0400 (mol / L);

[0098] m - the mass of the sample in step B is 0.2000g;

[0099] V 0 - The volume of the standard titration solution of potassium dichromate consumed by the blank test solution for titration is 0.00ml;

[0100] V - titration sample solution consumes potassium dichromate standard titration solution volume is 6.95ml;

[0101] 55.85 - the mass per mole of iron, in grams per mole (g / mol).

[0102]

[0103]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com