An accurate, reliable, simple and rapid detection method for silicon, sulfur and phosphorus elements in steel-making exothermic agents

A detection method and heating agent technology, which is applied in the detection of silicon, phosphorus and sulfur in steelmaking heating agents, can solve the problems of long detection period, high cost, poor anti-interference, etc. High, high emission intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A. Standard sample preparation: According to the concentration range of silicon, sulfur, and phosphorus elements in the steelmaking heating agent, select samples with different concentration gradients of each element, and the concentration gradient values are shown in the following table:

[0045]

[0046] The silicon, sulfur and phosphorus elements of each sample were quantitatively analyzed by volumetric method, and the average value of three analyzes was taken, and the sample whose concentration was determined by quantitative analysis was used as the standard sample.

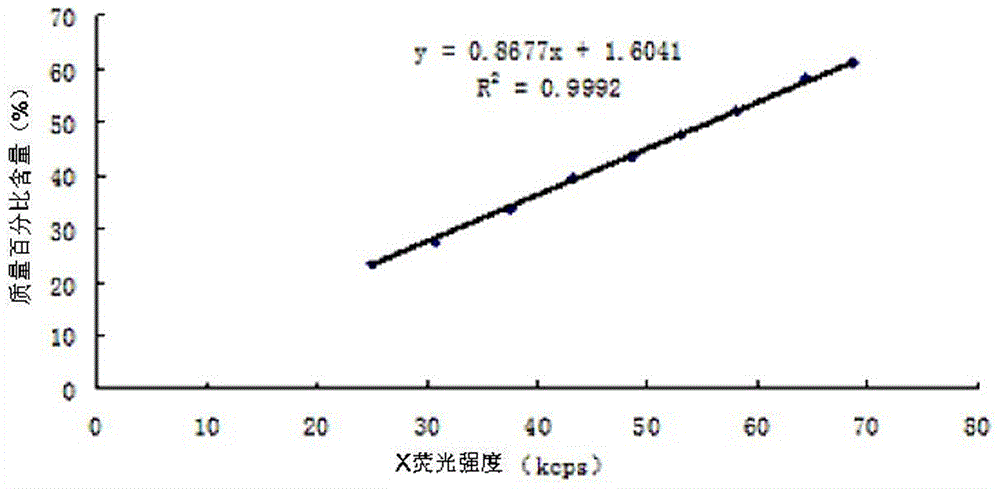

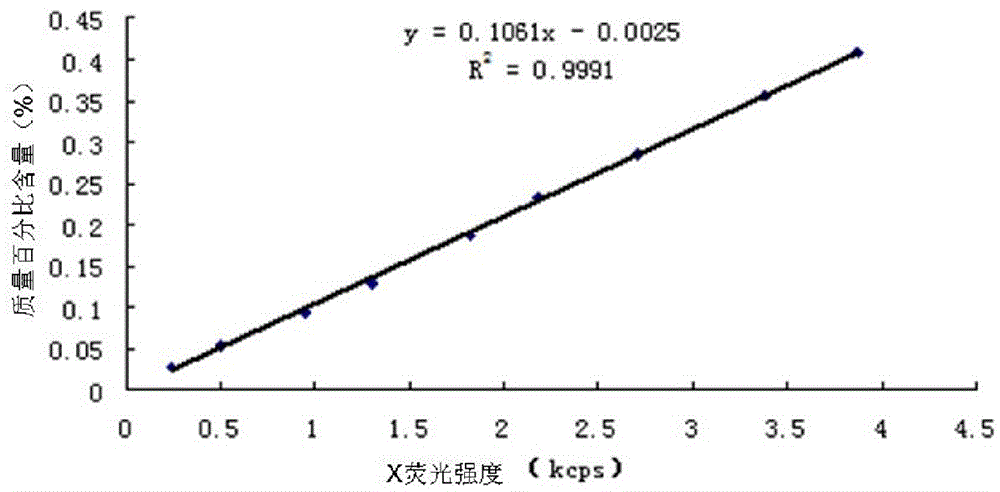

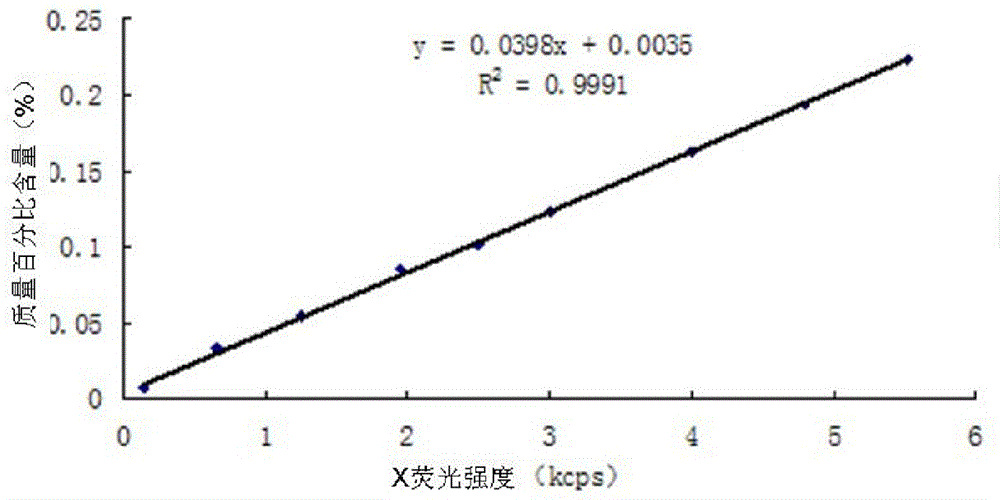

[0047] B. Drawing of the working curve: Dry 50g of the standard sample at 108°C for 60 minutes until it is absolutely dry, mix the standard sample with ethyl cellulose at a mass ratio of 1:0.07, add 2 drops of absolute ethanol, and put it in the grinding pool Grind for 100s and pass through a 200-mesh sieve to obtain the standard sample powder to be tested, then press it under a pressure of 40t for...

Embodiment 2

[0060] A, standard sample preparation: according to the concentration range of silicon, sulfur, phosphorus element in the heating agent of steelmaking, select the sample of different concentration gradient of each element, its concentration gradient value is the same as embodiment 1, adopt volumetric method to calculate the silicon content of each sample. , sulfur, and phosphorus elements were quantitatively analyzed, and the average value of three analyzes was taken, and the sample whose concentration was determined by quantitative analysis was used as the standard sample.

[0061] B. Working curve drawing: Dry 50g of the standard sample at 105°C for 65min until it is absolutely dry, mix the standard sample with boric acid at a mass ratio of 1:0.05, add 2 drops of absolute ethanol, and grind in the grinding pool for 10s. Pass through a 100-mesh sieve to obtain the standard sample powder to be tested, and then press it under a pressure of 5t for 50s to obtain a standard sheet; ...

Embodiment 3

[0073] A, standard sample preparation: according to the concentration range of silicon, sulfur, phosphorus element in the heating agent of steelmaking, select the sample of different concentration gradient of each element, its concentration gradient value is the same as embodiment 1, adopt volumetric method to calculate the silicon content of each sample. , sulfur, and phosphorus elements were quantitatively analyzed, and the average value of three analyzes was taken, and the sample whose concentration was determined by quantitative analysis was used as the standard sample.

[0074] B. Drawing the working curve: Dry 50g of the standard sample at 110°C for 55min until it is completely dry, mix the standard sample with methyl cellulose at a mass ratio of 1:0.09, add 1 drop of absolute ethanol, and put it in the grinding pool Grind for 180s and pass through a 200-mesh sieve to obtain the standard sample powder to be tested, and then press it under a pressure of 45t for 5s to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com