Fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite

A silicon dioxide and detection method technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of incomplete sample decomposition, long analysis time, analysis error, etc., achieve good promotion and application prospects, high analysis efficiency, and reduce the number of experiments effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] ——Determination of silica content in lime sample

[0048] Reagents for detection:

[0049] Sodium carbonate-boric acid mixed flux: It is made by mixing sodium carbonate and boric acid with a mass ratio of 2:1 and grinding them finely.

[0050] Hydrochloric acid solution: It is made by mixing 37% hydrochloric acid and water at a volume ratio of 1:1.

[0051] Ammonium molybdate solution: the concentration is 12.5g / L.

[0052] Mixed acid of oxalic acid-sulfuric acid: It is formed by mixing oxalic acid solution and sulfuric acid solution with a volume ratio of 3:1. become.

[0053] Mixed solution of ascorbic acid-ammonium ferrous sulfate: mixed with ascorbic acid solution and ammonium ferrous sulfate solution with a volume ratio of 1:1, the concentration of ascorbic acid solution is 2.0g / L, and the concentration of ferrous ammonium sulfate solution is 2.0g / L L.

[0054] Silica standard sample: the purity is 99.99%.

[0055] Sample testing:

[0056] A. Sample pretreat...

Embodiment 2

[0071] ——Determination of silica content in limestone samples

[0072] Detection reagent: same as embodiment 1

[0073] Sample testing:

[0074] A. Sample pretreatment: crush the limestone sample to a particle size of ≤0.125mm, dry at 108°C for 2 hours, seal the sample in a desiccator immediately after drying, and cool to 20~25°C.

[0075] B, C, D, E, F steps are the same as embodiment 1.

[0076] G. Calculation of content: the calculation of silica content in limestone sample is as follows:

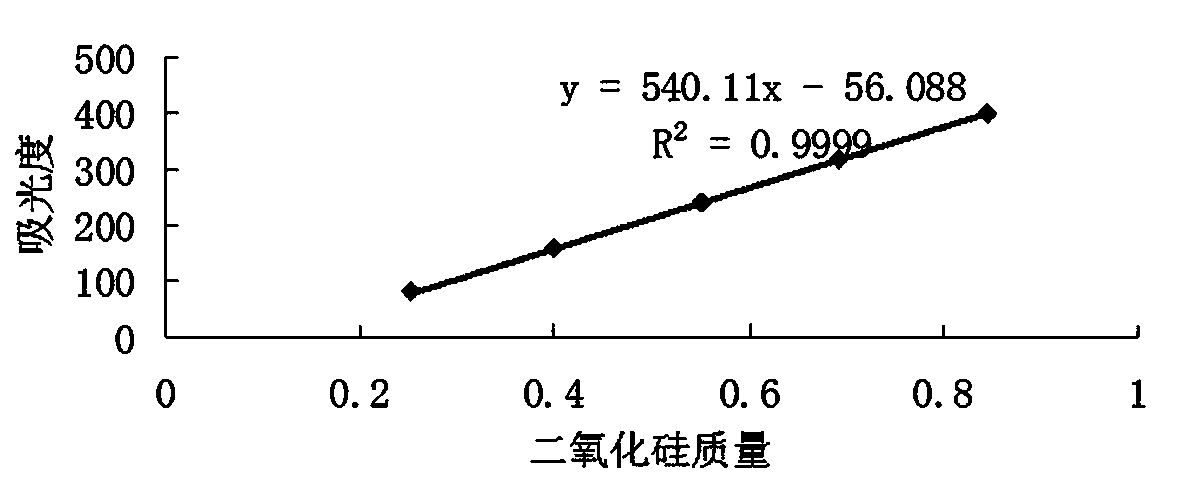

[0077] m 1 ——Based on the limestone sample absorbance value of 0.472, the quality of silica obtained from the working curve is 198.84ug;

[0078] m - the mass of the sample in step B is 0.1000g;

[0079] V 1 - The volume of the test solution pipetted in step C is 5.00ml;

[0080] V—the total volume of the test solution in step B is 250ml.

[0081]

[0082] =

[0083] = 9.94 (%)

Embodiment 3

[0085] ——Determination of silica content in dolomite samples

[0086] Detection reagent: same as embodiment 1

[0087] Sample testing:

[0088] A. Sample pretreatment: crush the dolomite sample to a particle size of ≤0.125mm, dry at 108°C for 2 hours, seal the sample in a desiccator immediately after drying, and cool to 20~25°C.

[0089] B, C, D, E, F steps are the same as embodiment 1.

[0090] G. Calculation of content: the calculation of silica content in the sample is as follows:

[0091] m 1 ——Based on the absorbance value of the dolomite sample 0.336, the quality of silica obtained from the working curve is 125.39ug;

[0092] m - the mass of the sample in step B is 0.1000g;

[0093] V 1 - The volume of the test solution pipetted in step C is 5.00ml;

[0094] V—the total volume of the test solution in step B is 250ml.

[0095]

[0096] =

[0097] = 6.27 (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com