Manufacturing method of titanium rolled composite plate

A manufacturing method and composite plate technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as the reduction of the interfacial bond strength of the composite plate, reduce interface reactions, improve interface bond strength, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

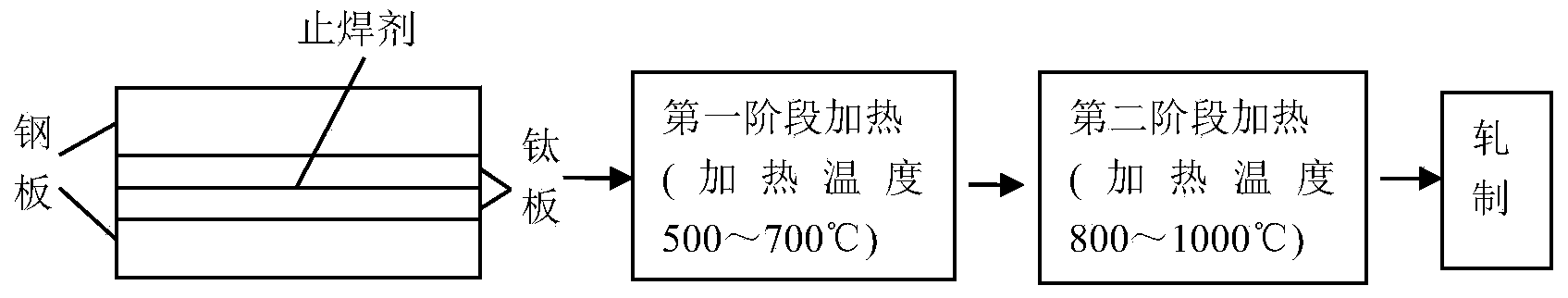

[0021] 1. Manufacture of TA1-Q235 rolled clad plate

[0022] TA1 and Q235 plates are obtained by the usual preparation method. The thickness of TA1 plate is 5mm, and the thickness of Q235 plate is 20mm. Cut 2 pieces of TA1 and Q235 plates of the same size, with a length of 1000mm and a width of 500mm. After grinding the TA1 and Q235 plates with abrasive belts, apply solder stopper in the middle of the two TA1 plates and stack them together, and put the Q235 steel plate on the outside of the TA1 plate for welding and assembly to form a Q235-TA1-TA1-Q235 four-layer plate structure . Put the sealed and welded composite plate into the heat treatment furnace, firstly keep it at 600°C for 60 minutes, then heat it to 850°C for 15 minutes, take it out and roll it directly, the reduction in one pass is 60%.

[0023] 2. Manufacture of TA2-Q235 rolled clad plate

[0024] The TA2 and Q235 plates are obtained by the usual preparation method. The thickness of the TA2 plate is 5mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com