Ni-Ni2O3 nano composite material and preparation

A technology of nanocomposite materials and nanowires, which is applied in the direction of nanotechnology, inorganic material magnetism, etc., can solve the problems of catalytic activity, Ni ferromagnetism, etc., to improve light absorption performance, improve utilization efficiency and photocatalysis effect, overcoming the effect that is difficult to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 2.37g NiCl 2 ·6H 2 O powder is dissolved in 50ml ethanol solution, and 0.8g NaOH is added, the mixed solution is fully stirred to make the components evenly mixed; 1ml of 80% hydrazine hydrate is added to the mixed solution, and the mixture is fully stirred; transfer the mixed solution to In an 80ml autoclave, after reacting at 200℃ for 2.5 hours, the reactor was naturally cooled to room temperature; the reactor was opened, the black precipitate at the bottom was taken out, washed with water, and dried to obtain the final Ni-Ni 2 O 3 Nanocomposite.

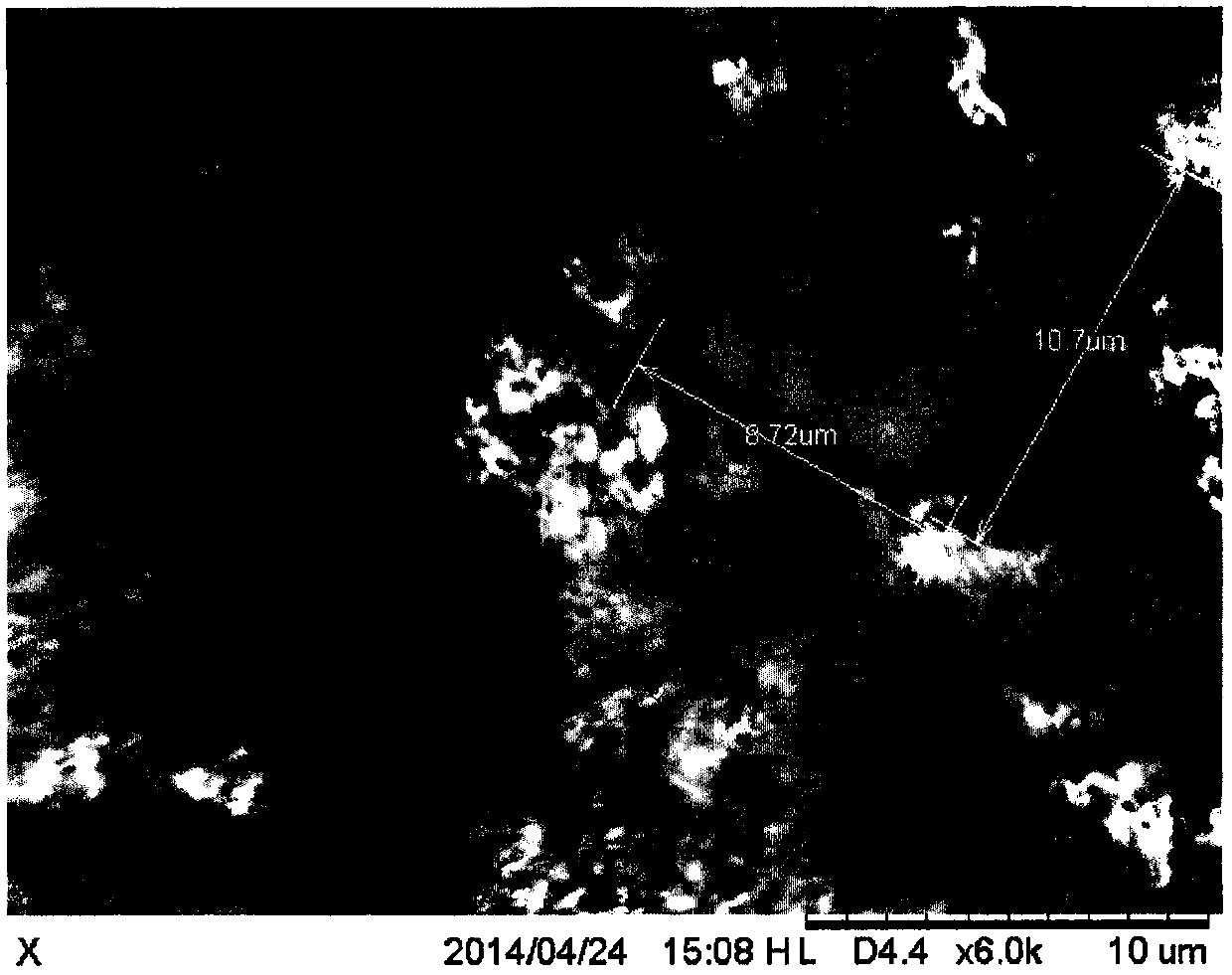

[0024] The morphology of the powder sample was observed using the 1530VP field emission scanning electron microscope of the German LEO company. The measurement results are as attached in the instruction manual. figure 1 Shown. It can be seen from the figure that Ni is a nanowire, and Ni 2 O 3 Exist in particle form.

Embodiment 2

[0026] 2.37g NiCl 2 ·6H 2 O powder is dissolved in 50ml ethanol solution, and 1.12g KOH is added, the mixed solution is fully stirred to make the components evenly mixed; 1ml of 80% hydrazine hydrate is added to the mixed solution, and the mixture is fully stirred; transfer the mixed solution to In an 80ml autoclave, after reacting for 3 hours at a temperature of 150°C, the reactor was naturally cooled to room temperature; the reactor was opened, the black precipitate at the bottom was taken out, washed and dried to obtain the final Ni-Ni 2 O 3 Nanocomposite.

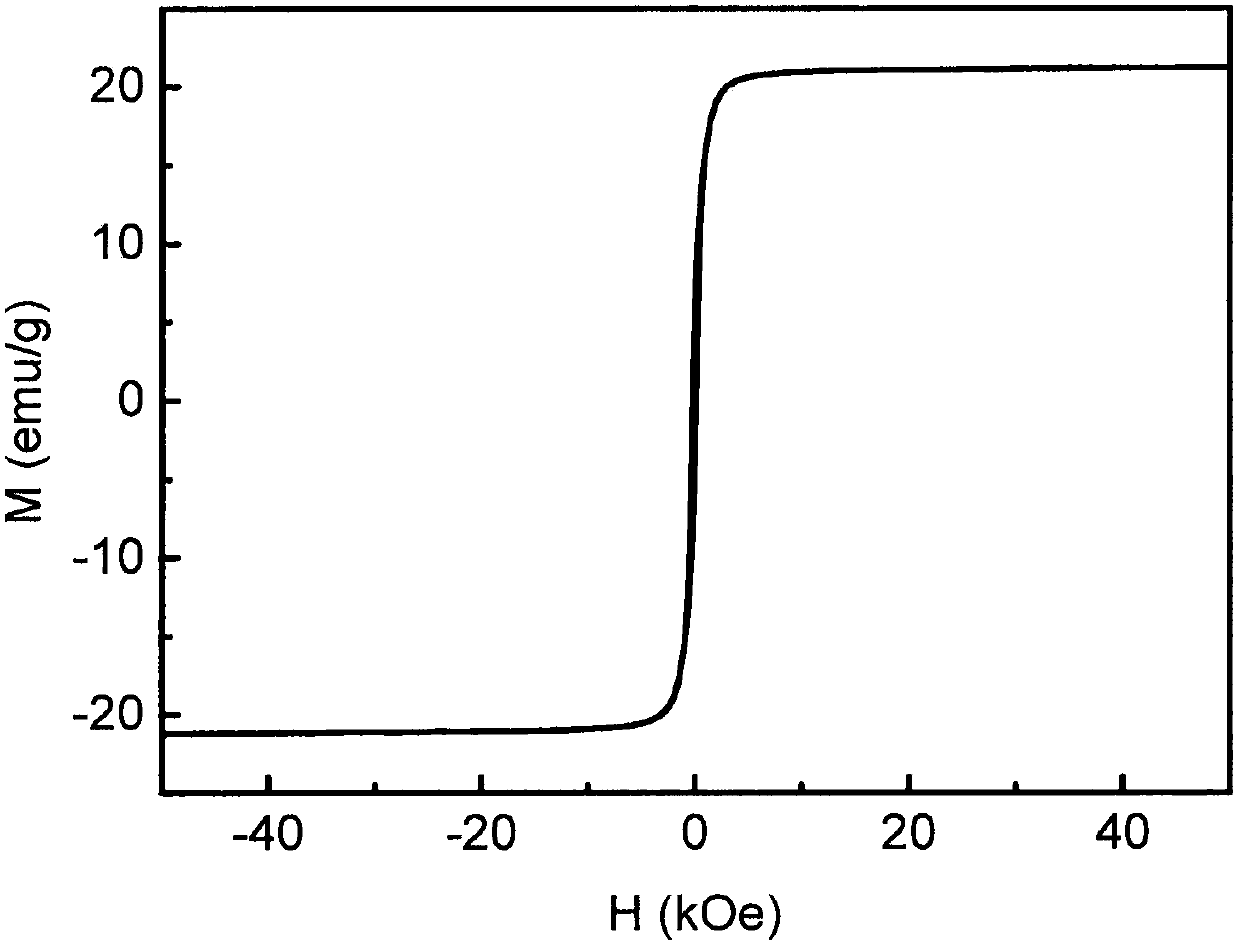

[0027] A magnetic measuring instrument (MPMS-9) was used to measure the room temperature hysteresis loop, and the measurement results are as attached in the manual figure 2 Shown. It can be seen from the figure that the material is ferromagnetic at room temperature, and the saturation magnetization is 21.2emu / g.

Embodiment 3

[0029] 2.37g NiCl 2 ·6H 2 O powder is dissolved in 50ml of ethanol solution, and 0.8g of NaOH is added, the mixed solution is fully stirred to make the components evenly mixed; 1ml of 80% hydrazine hydrate is added to the mixed solution, and the mixture is fully stirred; transfer the mixed solution to In a 100ml autoclave, after reacting for 2 hours at a temperature of 180°C, the reactor was naturally cooled to room temperature; the reactor was opened, and the black precipitate at the bottom was taken out, washed and dried to obtain the final Ni-Ni 2 O 3 Nanocomposite.

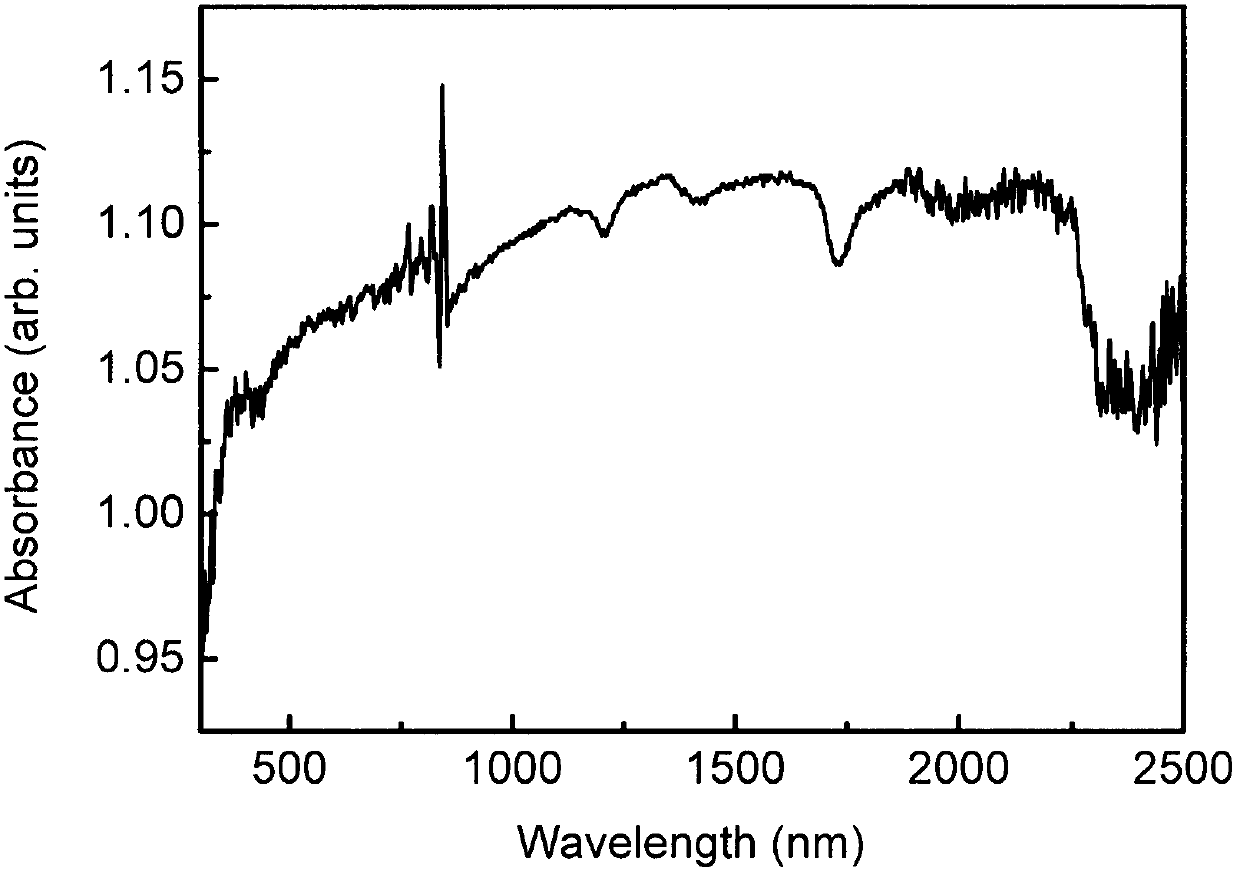

[0030] The optical absorption spectrum was measured with Hitachi's UV-Visible Spectrophotometer (HITACHI UV-4100), and the measurement results are shown in the instructions attached. image 3 Shown. It can be seen from the figure that the sample material has strong absorption characteristics in the wavelength range from 350nm to 2300nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com