Preparation method of semi-interpenetrating gel polymer electrolyte doped with ion complex

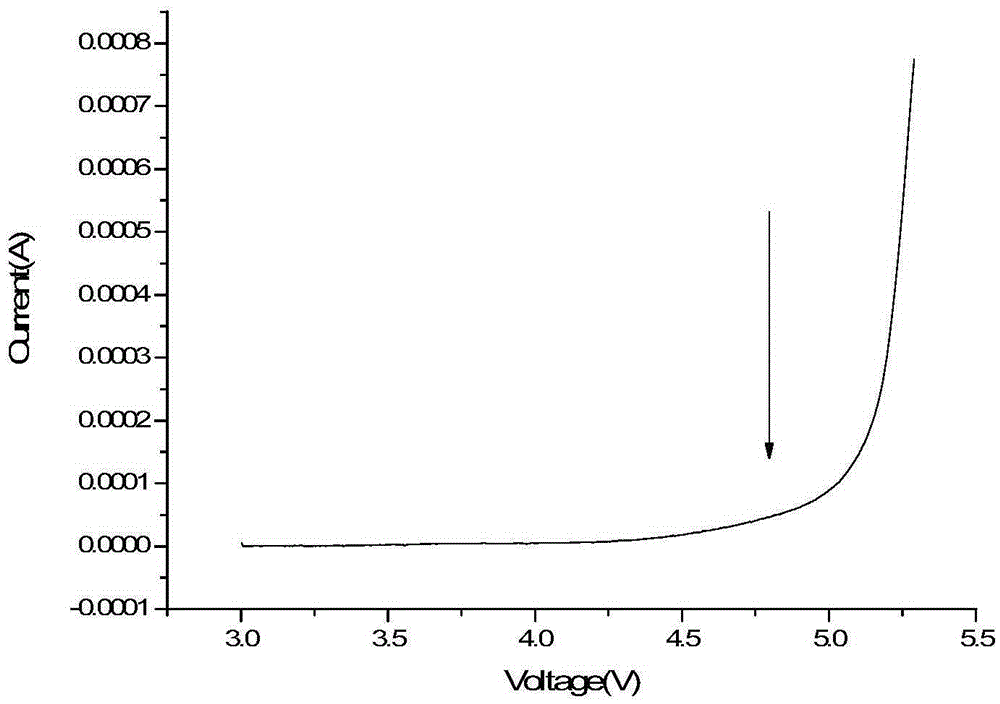

A gel polymer and ion-doped technology, which is applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of ineffective system modification, poor compatibility of polymer matrix, and high surface energy of inorganic particles. Increase the electrochemical stability window, increase the degree of disorder, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

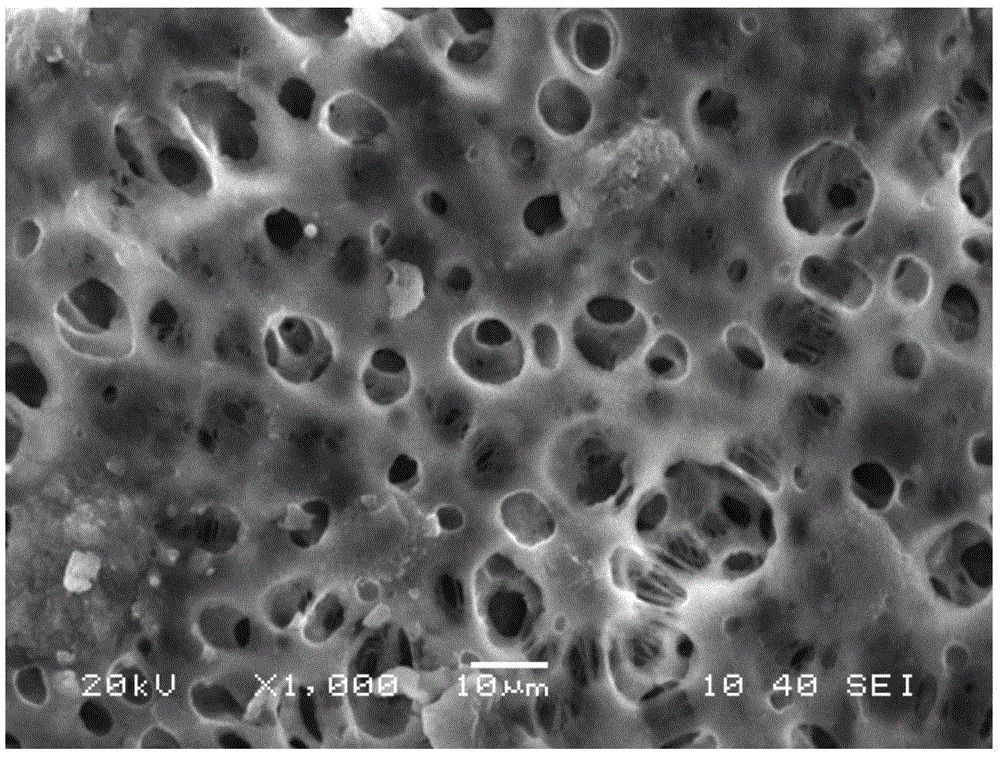

[0020] 1) Disperse 1g of Degussa A300 fumed silica and 0.05g of γ-methacryloxypropyltrimethoxysilane in a mixed solvent of 40ml of ethanol and 10ml of water, and use hydrochloric acid as a catalyst to adjust the reaction system The pH of the solution is 3, and the temperature is raised with stirring so that the reaction temperature is around 70°C for 6 hours. The obtained product is first filtered and then baked in a vacuum oven at 100°C for 6 hours. The obtained γ-methacryloyloxypropyl Mix and disperse 1g of trimethoxysilane grafted fumed silica powder with 5g of acrylic acid in deionized water, the concentration of the mixture solution is 1g / ml, then add 0.03g of ammonium persulfate, stir and heat up and react at 80°C for 9 hours Cool down to 50°C, then add 0.1g / ml lithium hydroxide aqueous solution to the system, the added lithium hydroxide is in equimolar amount to the acrylic acid in the reaction system, react the system at 50°C for 2 hours, and filter the obtained product...

Embodiment 2

[0026] 1) Disperse 1g of Degussa A200 fumed silica and 0.0625g of γ-methacryloxypropyltrimethoxysilane in a mixed solvent of 30ml of ethanol and 15ml of water, and use hydrochloric acid as a catalyst to adjust the reaction system The pH of the solution is 2, and the temperature is raised with stirring so that the reaction temperature is 60°C for 7 hours. The obtained product is first filtered and then heated and dried in a vacuum oven at 80°C for 8 hours. The obtained γ-methacryloyloxypropyltrimethyl Disperse 1g of oxysilane-grafted fumed silica powder and 2g of acrylic acid in deionized water, the concentration of the mixture solution is 1g / ml, then add 0.02g of ammonium persulfate, stir and heat up at 70°C for 10 hours and then cool down to 50°C ℃, and then add 0.1g / ml lithium hydroxide aqueous solution to the system, the added lithium hydroxide and the acrylic acid in the reaction system have an equimolar amount, and the system is reacted at 50 ℃ for 1 hour, and the obtained...

Embodiment 3

[0030] 1) Disperse 1g of Degussa A380 fumed silica and 0.1g of γ-methacryloxypropyltrimethoxysilane in a mixed solvent of 30ml of ethanol and 10ml of water, and use hydrochloric acid as a catalyst to adjust the reaction system The pH of the solution is 4, and the temperature is raised with stirring so that the reaction temperature is around 80°C for 5 hours. The obtained product is first filtered and then dried in a vacuum oven at 120°C for 4 hours. The obtained γ-methacryloyloxypropyltrimethyl Disperse 1g of oxysilane-grafted fumed silica powder and 3g of acrylic acid in deionized water, the concentration of the mixture solution is 1g / ml, then add 0.06g of ammonium persulfate, stir and raise the temperature in the range of 90°C for 8 hours, then cool down to 50°C, then add 0.1g / ml lithium hydroxide aqueous solution to the system, the added lithium hydroxide is in equimolar amount to the acrylic acid in the reaction system, the system reacts at 50°C for 1.5 hours, the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com