Composite artificial bone for enhancing osteogenic activity and preparation method thereof

An osteogenic activity and artificial bone technology, applied in the field of biomedical materials, can solve the problems of limited source of autologous bone transplantation, large immune rejection, and potential safety hazards, so as to improve biological activity and biocompatibility, and promote growth Bone activity, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Prepare a 10% collagen aqueous solution with deionized water.

[0042] Collagen is animal-derived full-length collagen, collagen polypeptide, and gelatin.

[0043] Step 2: Add nano-hydroxyapatite powder into the collagen aqueous solution in batches, the mass ratio of collagen to hydroxyapatite is 1:2, and mix well on a vortex shaker at room temperature.

[0044] Step three: quickly transfer the mixture obtained in step three to the mold.

[0045] Step 4: Pre-freeze the mold at 4°C for 20 minutes, then move to -20°C for 1 hour, transfer to -80°C for 3 hours, and then dry in a vacuum freeze dryer for 12 hours.

[0046] Step 5: prepare a 2% olive polyphenol solution with an ethanol solution, and adjust the pH to 6.

[0047] The ethanol solution is an aqueous ethanol solution with a mass fraction of 75%; the pH regulator is selected from sodium hydroxide solution or hydrochloric acid solution, and the molar volume concentration is 0.1mol / L.

[0048] Step 6: Incub...

Embodiment 2

[0051] Step 1: Prepare a 15% collagen aqueous solution with deionized water.

[0052] Collagen is recombinant collagen or human-like collagen produced by genetic engineering.

[0053]Step 2: Add nano-hydroxyapatite powder into the collagen aqueous solution in batches, the mass ratio of collagen to hydroxyapatite is 1:3, and mix well on a vortex shaker at room temperature.

[0054] Step three: quickly transfer the mixture obtained in step three to the mold.

[0055] Step 4: Pre-freeze the mold at 4°C for 40 minutes, then move to -20°C for 1.5 hours, transfer to -80°C for 4.5 hours, and then dry in a vacuum freeze dryer for 30 hours.

[0056] Step 5: Prepare a 3% olive polyphenol solution with an ethanol solution, and adjust the pH to 7.

[0057] The ethanol solution is an aqueous ethanol solution with a mass fraction of 85%; the pH regulator is potassium hydroxide solution and sulfuric acid solution, both of which have a molar volume concentration of 0.5 mol / L.

[0058] Step...

Embodiment 3

[0061] Step 1: prepare a collagen aqueous solution with a mass fraction of 25% with deionized water.

[0062] Collagen is recombinant collagen or human-like collagen produced by genetic engineering.

[0063] Step 2: Add the nano-hydroxyapatite powder into the collagen aqueous solution in batches, the mass ratio of collagen to hydroxyapatite is 1:4, and mix well on a vortex shaker at room temperature.

[0064] Step three: quickly transfer the mixture obtained in step three to the mold.

[0065] Step 4: Pre-freeze the mold at 4°C for 60 minutes, then move to -20°C for 2 hours, transfer to -80°C for 6 hours, and then dry in a vacuum freeze dryer for 48 hours.

[0066] Step 5: Prepare a 5% olive polyphenol solution with an ethanol solution, and adjust the pH to 8.

[0067] The ethanol solution is an aqueous ethanol solution with a mass fraction of 95%; the pH regulator is sodium carbonate solution or phosphoric acid solution, and the molar volume concentration is 1mol / L.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

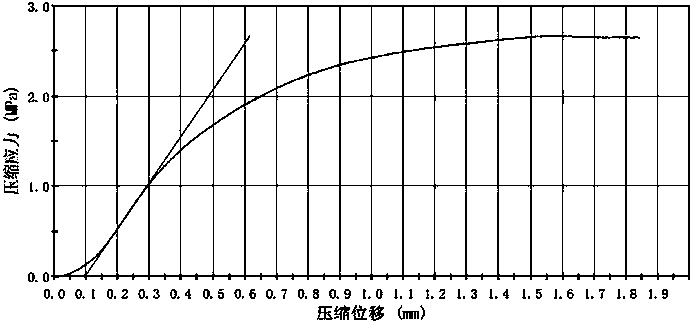

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com