Lithium ion battery carbon negative electrode material grinding shaping technological process and production system thereof

A technology of carbon negative electrode materials and lithium-ion batteries, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of large power consumption, high production costs, and low yield of finished products, so as to improve the degree of automation and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

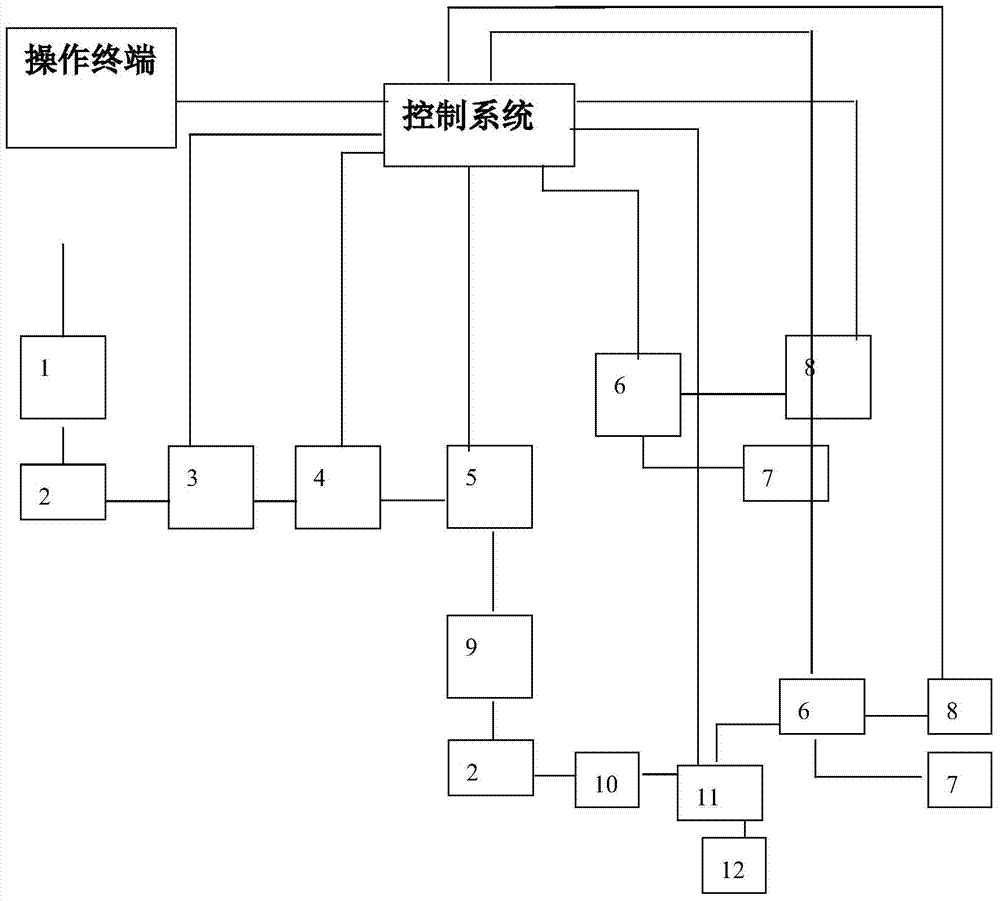

Method used

Image

Examples

Embodiment 1

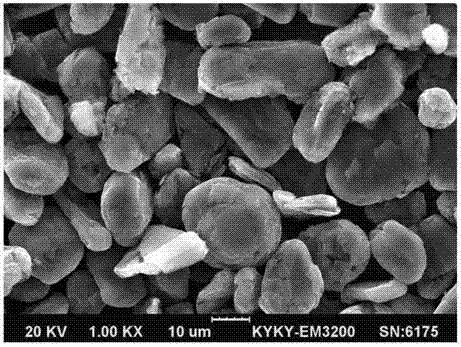

[0059] The natural flake graphite with a particle size of 32 mesh and a carbon content of more than 90% is sent to the closed silo of the ultra-fine grinding mill through a high-pressure sealed pipeline with a pressure of 0.6 MPa, and the automatic quantitative feeding system feeds the carbon into the closed silo. The graphite is sent to an ultrafine grinding mill (CXM400 ultrafine mill) for internal grinding and grinding. The main engine speed of the ultrafine grinding mill is 1500rpm / min, the turbine speed of the internal submachine is 300rpm / min, and the grinding time is 30 minutes. Under the rotation of the inner grading turbine, the particles with qualified particle size flow out automatically with the airflow, and the coarse particles fall into the crushing area and continue to be crushed until they are qualified. Adjust the crushing parameters of the ultra-fine grinding mill to produce D 50 18μm graphite powder.

[0060] Will D 50 Graphite powder with a size of 18 μm a...

Embodiment 2

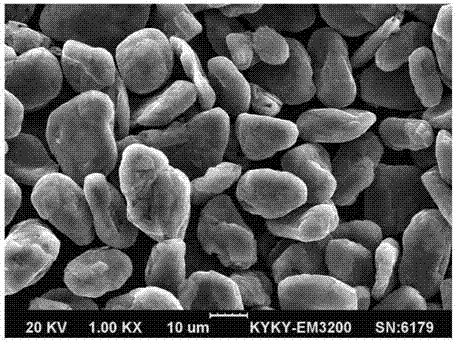

[0064] The natural flake graphite with a particle size of 32 mesh and a carbon content of more than 90% is sent to the closed silo of the ultra-fine grinding mill through a high-pressure sealed pipeline with a pressure of 0.6 MPa, and the automatic quantitative feeding system feeds the carbon into the closed silo. The graphite is sent to an ultrafine grinding mill (CXM400 ultrafine mill) for internal grinding and grinding. The main engine speed of the ultrafine grinding mill is 1500rpm / min, the turbine speed of the internal submachine is 300rpm / min, and the grinding time is 30 minutes. Under the rotation of the inner grading turbine, the particles with qualified particle size flow out automatically with the airflow, and the coarse particles fall into the crushing area and continue to be crushed until they are qualified. Adjust the crushing parameters of the ultra-fine grinding mill to produce D 50 23μm graphite powder.

[0065] Will D 50 Graphite powder with a size of 23μm au...

Embodiment 3

[0068] Artificial graphite with a particle size of 100 mesh and a carbon content of more than 90% is sent to the closed silo of the ultra-fine grinding mill through a high-pressure sealed pipeline with a pressure of 0.3 Pa, and the graphite in the closed silo is sent to Enter an ultrafine grinding mill (CXM400 type ultrafine mill) to grind and pulverize. The main engine speed of the ultrafine grinding mill is 2000rpm / min, the turbine speed of the internal submachine is 400rpm / min, and the grinding time is 20 minutes. Under the rotation of the inner grading turbine, the particles with qualified particle size flow out automatically with the airflow, and the coarse particles fall into the crushing area and continue to be crushed until they are qualified. Adjust the crushing parameters of the ultra-fine grinding mill to produce D 50 20μm graphite powder.

[0069] Will D 50 Graphite powder with a size of 20 μm automatically flows into the centrifugal air classifier with the air fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com