Tb<3+>/Yb<3+> double doped lithium lutetium fluoride single crystal for solar spectrum modulation and preparation method thereof

A technology of lithium lutetium fluoride and solar spectrum, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of poor stability and performance of glass materials, and achieve simple preparation methods, excellent thermal properties, and phonon energy low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

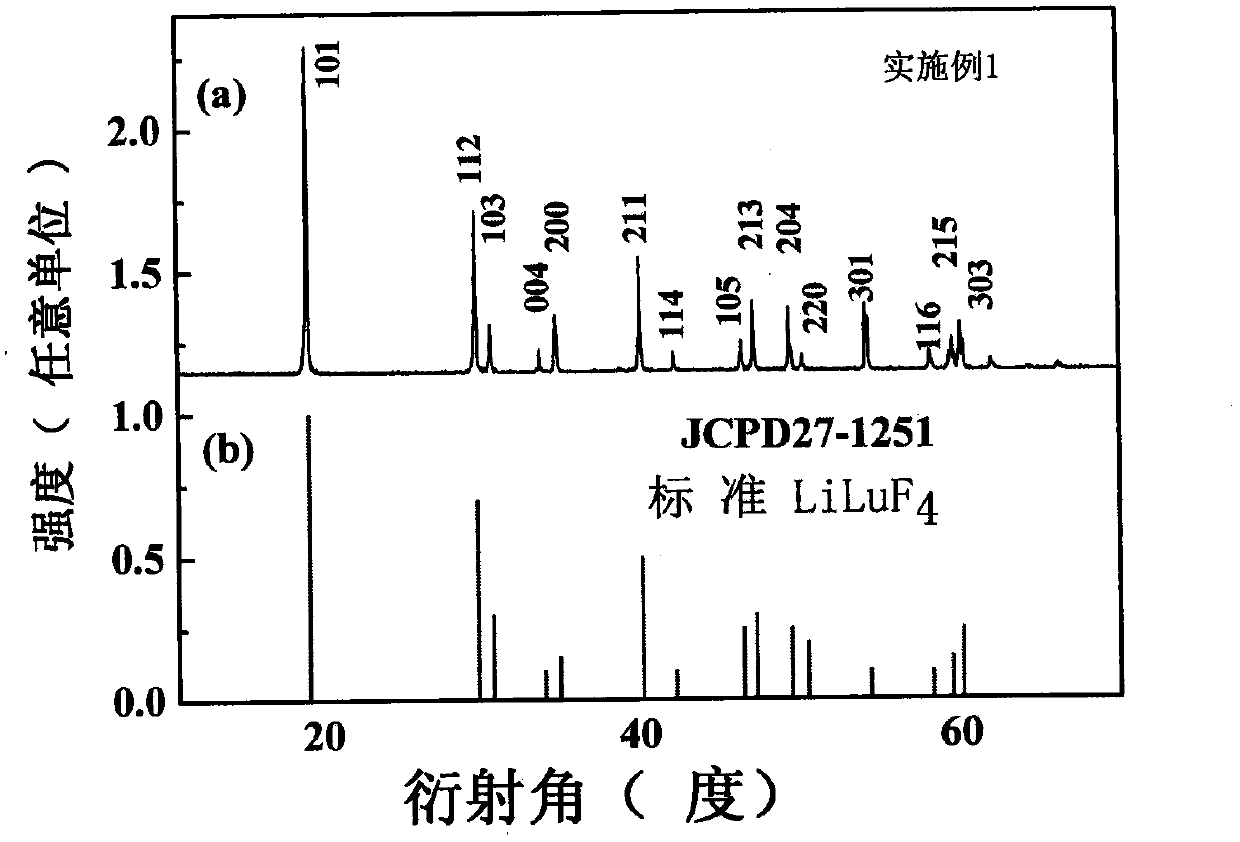

Embodiment 1

[0020] LiF and YF with purity greater than 99.99% 3 , TbF 3 , YbF 3 Mix according to the mole percentage of 51.5:40.45:0.25:7.80, place it in a mill, grind and mix for 5 hours to obtain a uniform powder mixture. The mixture is placed in a boat-shaped platinum crucible, and then installed in a tubular resistance furnace In the platinum pipe, then first use N 2 Exhaust the air in the platinum pipeline, and then gradually increase the temperature of the furnace body to a temperature of 800 ℃. Under the HF gas, the reaction treatment is 2 hours, and the reaction treatment is completed. During the treatment, the HF tail gas is absorbed by NaOH solution, and the HF gas and Tubular resistance furnace, use N 2 Purge the residual HF gas in the pipeline and gradually cool it to room temperature to obtain polycrystalline powder. The polycrystalline powder is ground into powder by a mill, and then placed in a Pt crucible and compacted. The Pt crucible is sealed and the sealed The Pt crucibl...

Embodiment 2

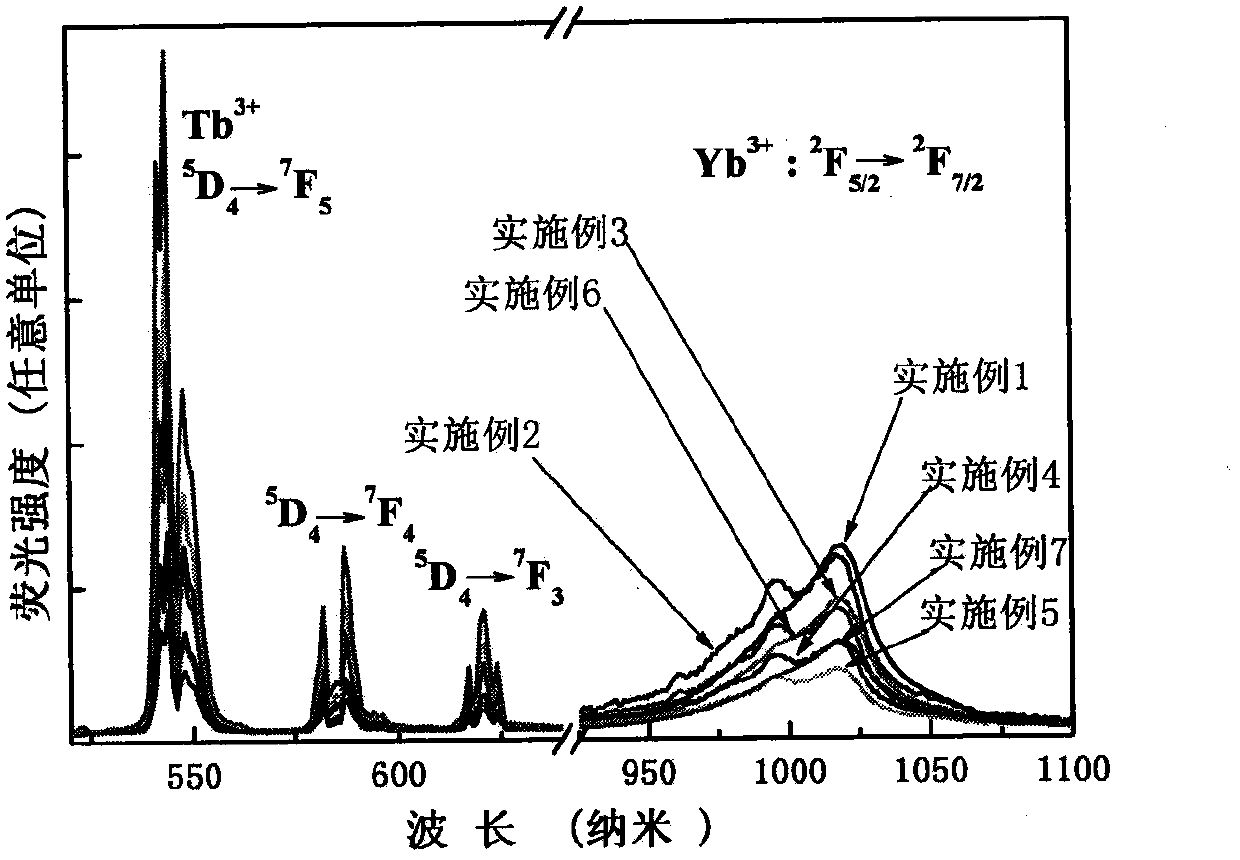

[0022] Basically the same as Example 1, except LiF, LuF 3 , TbF 3 , YbF 3 Molar percentage 51.5:36.25:0.25:12.00, reaction treatment for 3 hours, temperature gradient of solid-liquid interface is 90℃ / cm, crucible descending speed is 0.5mm / h, after crystal growth is over, the furnace temperature is lowered at 50℃ per hour To room temperature, sampling and measuring x = 0.0730, y = 0.0032, the chemical formula of the single crystal is LiLu 0.9238 Yb 0.073 Tb 0.0032 F 4 . The X-ray diffraction pattern of the sample is similar to Example 1. Then, each obtained sample was polished into a thin slice with a thickness of 2 mm, maintaining the same optical test conditions as in Example 1, and the obtained fluorescence intensity was comparable to that in Example 1. Under 486nm light excitation, fluorescence spectroscopy and Tb 3+ Characteristic 542nm fluorescence lifetime test. See the test results figure 2 , 900-1000nm fluorescence intensity is 91 units. According to the test result...

Embodiment 3

[0024] Basically the same as Example 1, except LiF, LuF 3 , TbF 3 , YbF 3 The molar percentage is 51.5:34.25:0.25:14.00, the reaction treatment is 4 hours, the temperature gradient of the solid-liquid interface is 80℃ / cm, the crucible descending speed is 1mm / h, after the crystal growth is over, the furnace temperature is lowered to 70℃ per hour. At room temperature, sampling and measuring x = 0.0540, y = 0.0033, the chemical formula of the single crystal is LiLu 0.9427 Yb 0.054 Tb 0.0033 F 4 . The X-ray diffraction pattern of the sample is similar to Example 1. Then, each obtained sample was polished into a thin slice with a thickness of 2 mm, maintaining the same optical test conditions as in Example 1, and the obtained fluorescence intensity was comparable to that in Example 1. Under 486nm light excitation, fluorescence spectroscopy and Tb 3+ Characteristic 542nm fluorescence lifetime test. See the test results figure 2 , 900-1000nm fluorescence intensity is 75 units. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence | aaaaa | aaaaa |

| fluorescence | aaaaa | aaaaa |

| fluorescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com