Barium strontium titanate/polystyrene core-shell structure and preparation method thereof

A technology of barium strontium titanate and polystyrene, which is applied in the field of advanced nanostructured materials, can solve the problems of large kinetic factors, difficult control of composite particle shape and particle size, complex nucleation mechanism of emulsion polymerization, etc., and achieves simple polymerization mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

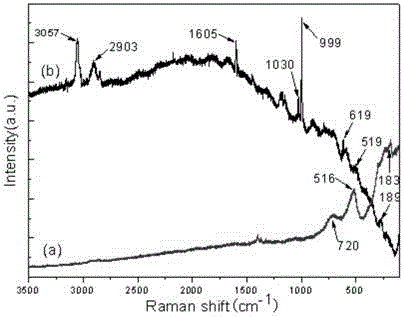

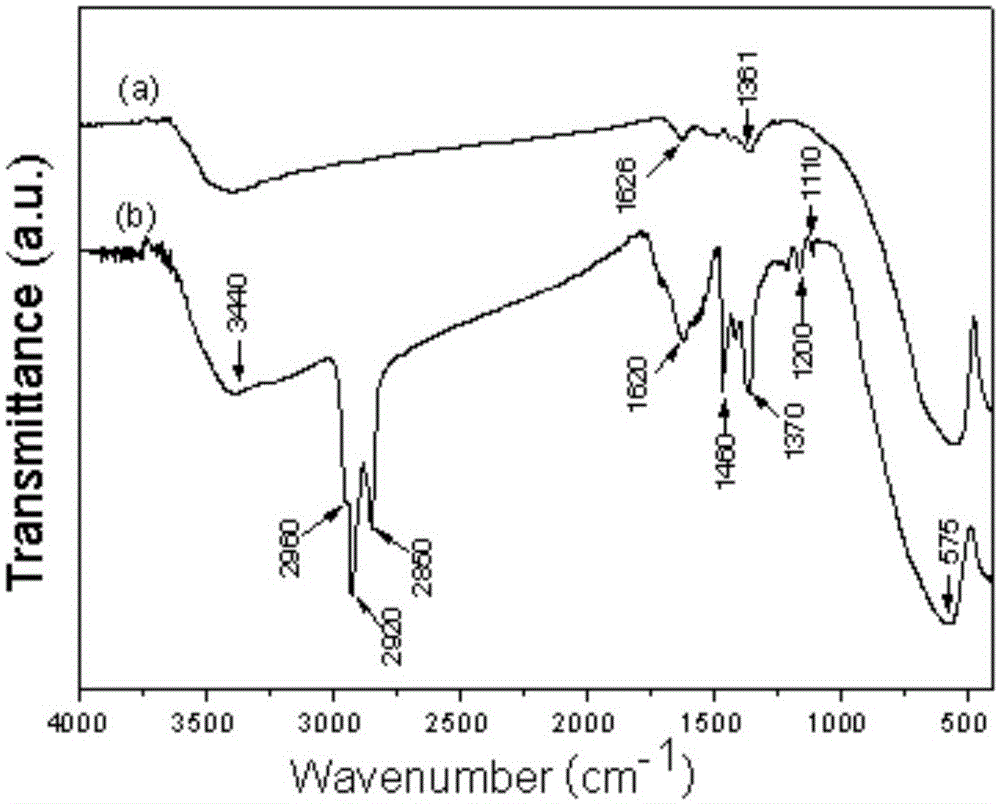

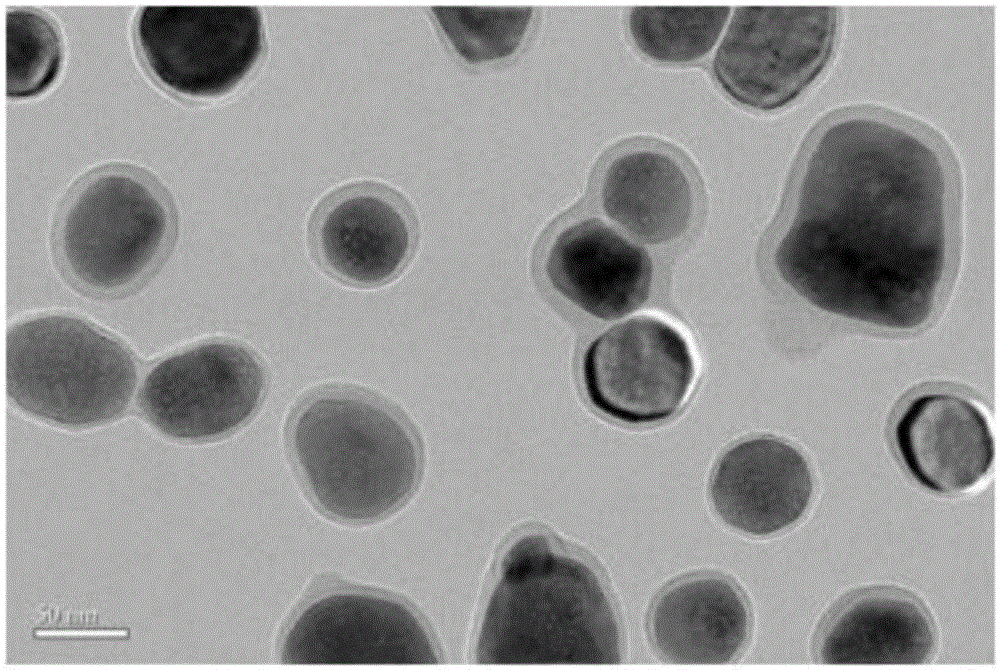

Embodiment 1

[0027] Utilize the method provided by the invention to prepare the strontium barium titanate / polystyrene core-shell structure whose shell thickness is 10nm, its operation steps are as follows:

[0028] (1) 25 mg of strontium barium titanate nanocrystals prepared by microwave-assisted Glycothermal method (chemical formula is Ba 0.6 Sr 0.4 TiO 3 ) was ultrasonically dispersed in 40ml of methanol, the ultrasonic power was 100W, and the ultrasonic time was 10min; 3.34g of the initiator 2-bromo-2-methylpropionic acid (Br-MPA) was added, and magnetically stirred at room temperature for 72h under an Ar protective atmosphere, and stirred The speed is 20rpm;

[0029] (2) Separate the initiator-modified nanocrystals from the liquid phase at a centrifugation speed of 8000rpm for 25 minutes; wash the residual initiator molecules with a mixed solvent of cyclohexane-ethanol, in which the mass fraction of ethanol is 30%, after three times After washing and centrifugation, the obtained ini...

Embodiment 2

[0034] Utilize the method provided by the invention to prepare the strontium barium titanate / polystyrene core-shell structure whose shell thickness is 15nm, its operation steps are as follows:

[0035] (1) 40 mg of strontium barium titanate nanocrystals prepared by microwave-assisted Glycothermal method were ultrasonically dispersed in 60 ml of methanol, the ultrasonic power was 150 W, and the ultrasonic time was 8 min; the initiator 2-bromo-2-methylpropionic acid (Br-MPA ) 10.02g, magnetically stirred at room temperature for 96h under an Ar protective atmosphere, and the stirring speed was 30rpm;

[0036] (2) Separate the nanocrystals modified by the initiator from the liquid phase at a centrifugation speed of 10,000 rpm for 15 minutes; wash the residual initiator molecules with a mixed solvent of cyclohexane-ethanol, in which the mass fraction of ethanol is 20%, after three times After washing and centrifugation, the obtained initiator-modified wet nanocrystals were irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com