Fabrication method of wire electrode array structure for micro electrolytic machining

A technology of array structure and micro electrolysis, which is applied in the fields of machining electrodes, electric machining equipment, electrode manufacturing, etc., can solve the problems of low machining efficiency, difficulty in machining high aspect ratio microstructures, insufficient machining accuracy, etc. The effect of improving locality and improving steepness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

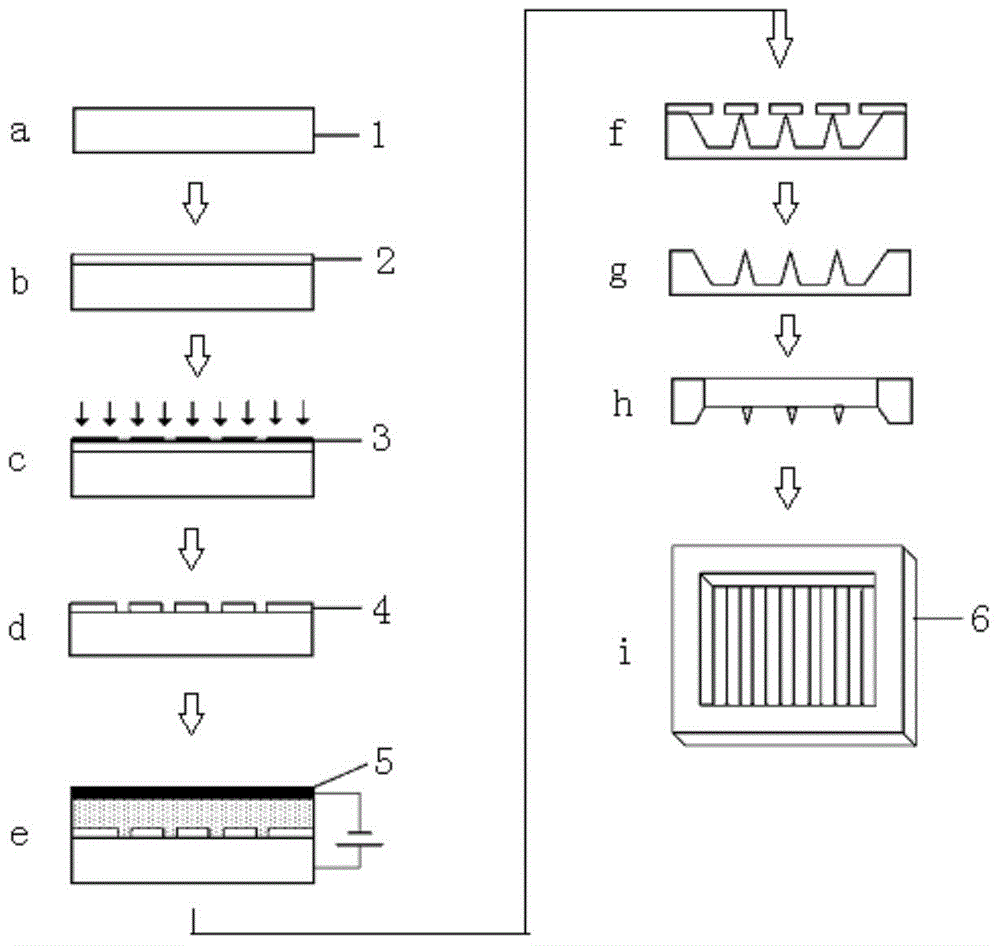

[0035] refer to figure 1 , the method for preparing a wire electrode array structure for micro-electrolytic machining of the present invention (describing the process of mask electrolytic deep etching combined with removal of back material to prepare wire electrodes), specifically includes the following steps:

[0036] Step 1. Pretreatment of the metal substrate: the metal substrate 1 is made of copper material. The purpose of the treatment is to make the surface of the sample smooth, clean and dry, and to be able to better adhere to the photoresist. The specific method is to polish the metal substrate 1 on a polishing machine. Polishing treatment to make the surface roughness Ra≤0.3, then use acetone, alcohol and deionized water to clean in sequence, then blow dry with nitrogen and dry on the dryer for use (see figure 1 a).

[0037] Step 2. Fabrication of patterned masking film for mask electrolytic processing: the masking film needs to have good electrical insulation. In th...

Embodiment

[0049] refer to Figure 4 , is the application of the electrode made by the method of the present invention, adopts the wire electrode array of the present invention to carry out metal microstructure array processing, implements according to the following steps:

[0050] Step 1, workpiece preparation ( Figure 4 a): The surface of the workpiece 10 to be processed is polished, cleaned, and dried for use;

[0051] Step 2, tool electrode preparation ( Figure 4 b): Using the above-mentioned wire electrode array manufacturing method (for the process principle, see figure 1 ) to make a wire electrode with integrated wire and frame, and control the distance between the wire electrode wires by controlling the width of the photoresist masking film during wire electrode fabrication, so that when the above wire electrode is used for electrolytic machining, the wire electrode The influence of mutual stray corrosion between them is small enough to improve the localization of processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com