Preparation method of crystalline silicon SE solar cell and crystalline silicon SE solar cell

A technology of solar cells and crystalline silicon, which is applied in the field of solar cells, can solve the problems of uniform diffusion of crystalline silicon SE solar cells and difficulties in printing alignment, and achieve high photoelectric conversion efficiency, fine grid lines, and small series resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a method for preparing a crystalline silicon SE solar cell, comprising the following steps:

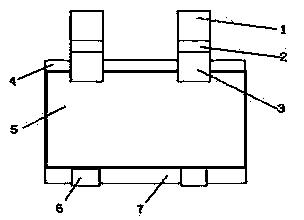

[0016] S1. Carry out texturing, diffusion, and dephosphorous silicon glass treatment on the surface of the silicon wafer 5, and then coat the silicon nitride anti-reflection film 4 on the front surface of the silicon wafer 5;

[0017] S2, covering one layer of metal mask on the surface of anti-reflection film 4, the shape of the hollow part of the metal mask is the same as the shape of the electrode grid line on the light-facing surface; then adopt magnetron sputtering to deposit oxidation on the anti-reflection film 4 Bismuth, the metal mask is removed after sputtering to obtain a bismuth oxide gate line layer;

[0018] S3. Print the back silver conductive paste on the back of the silicon wafer 5, print the back field aluminum paste after drying, sinter the silicon wafer as a whole in a tunnel furnace after drying, and perform annealing treatment after s...

Embodiment 1

[0043] (1) Texture-making, cleaning and drying, organophosphorus diffusion, etching, and phosphorus-silicon glass removal are carried out on the P-type polysilicon of 156×156mm, and then silicon nitride anti-reflection coating is coated on the front of the silicon wafer to obtain a P-type polysilicon wafer .

[0044] (2) Put the P-type polysilicon wafer on the loading table of the linear magnetron sputtering machine, cover the front with a metal molybdenum mask, fix the P-type polysilicon wafer and the metal molybdenum mask, and then place it as a whole. into the sputtering chamber, sputtering with bismuth oxide (purity > 99.9wt%) pre-fixed in the chamber as the target, close the door of the sputtering chamber, and vacuum the chamber such as argon, the sputtering pressure The temperature is 0.7Pa, the argon flow rate is 15sccm, the silicon wafer temperature is 240°C, and the sputtering time is 20s. After the sputtering is completed, remove the metal molybdenum mask plate to re...

Embodiment 2

[0049] The same steps as in Example 1 were used to prepare the crystalline silicon SE solar cell of this example, the difference being that:

[0050] In step (2), the P-type polysilicon wafer is placed on the loading table of the linear magnetron sputtering machine, and its front is covered with a metal molybdenum mask plate, and the P-type polysilicon wafer and the metal molybdenum mask plate are fixed, and then Put it into the sputtering chamber as a whole, use bismuth oxide (purity>99.9wt%) pre-fixed in the chamber as the target for sputtering, close the door of the sputtering chamber, vacuum the chamber and introduce argon gas , the sputtering pressure is 0.6Pa, the argon flow rate is 18sccm, the silicon wafer temperature is 240°C, and the sputtering time is 30s. After the sputtering is completed, remove the metal molybdenum mask to realize the oxidation of the gate line area of the P-type polysilicon wafer. Deposition of bismuth film, the thickness of the deposited bism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com