Ultra-strong strength, high-toughness and anticorrosive aluminum alloy and preparation method for same

A high-strength, high-toughness, aluminum alloy technology, applied in the field of aluminum alloys, can solve the problems of affecting the toughness of the alloy, high price, unbalanced application of rare earth elements, etc., and achieve the effect of high corrosion resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

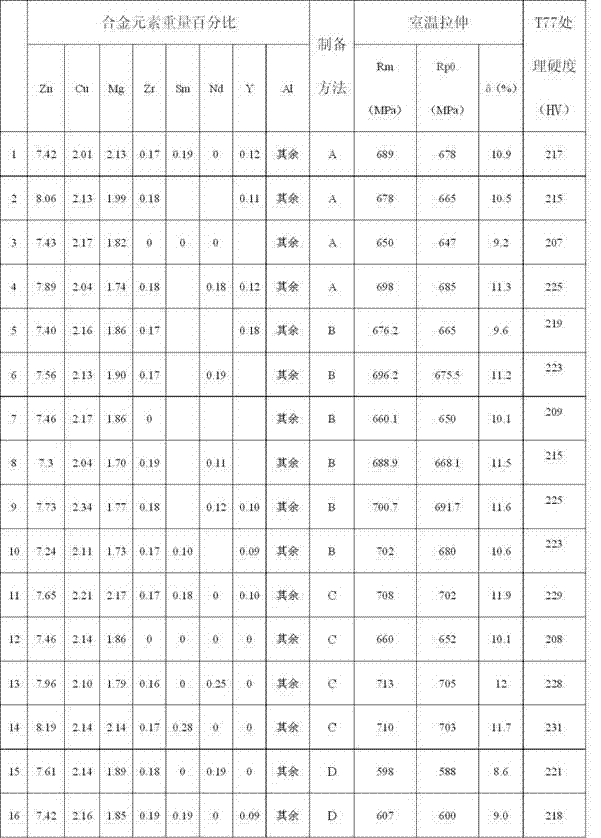

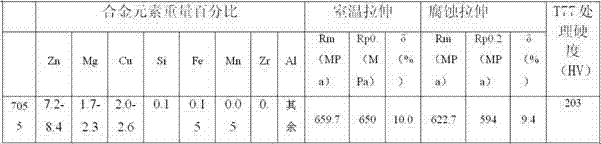

[0042] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by skilled personnel according to the present invention in practical applications still belong to the protection scope of the present invention.

[0043] Some examples are listed below to illustrate the invention and its beneficial effects.

[0044] The manufacturing methods of the aluminum alloys in the following examples respectively adopt the above-mentioned manufacturing method A, manufacturing method B, manufacturing method C, and manufacturing method D.

[0045] In the following examples, the mass fraction of impurity Si is less than 0.1%, Fe is less than 0.15%, the alloy element Mn is less than 0.05%, and Ti is less than 0.06%, without adding or adding any one or two of rare earth elements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com