A kind of conductive concrete and preparation method thereof

A conductive concrete and stainless steel technology, applied in the field of building materials, can solve the problems of increasing the difficulty of the preparation process, poor radial performance, difficult to popularize and apply, etc., and achieve the effect of good grounding drainage effect, stable electrical conductivity and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

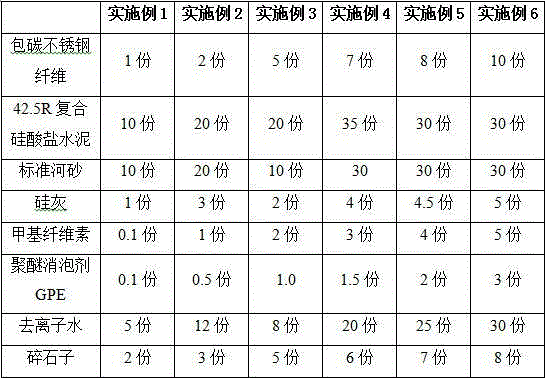

Examples

preparation example Construction

[0034] a. Preparation of carbon-coated stainless steel fibers:

[0035] Take 20 parts of carbon precursor (a mixture of maltose, glucose and cellulose), put them in a stainless steel hydrothermal reaction kettle together with 100 parts of stainless steel fibers, and stir well, control the reaction temperature to 300 ° C, and the reaction time to 2 h. The final stainless steel fiber is centrifuged to obtain purified carbon-coated stainless steel fiber;

[0036] Put the carbon-coated stainless steel fibers that have been purified and separated into a stainless steel hydrothermal reaction kettle, add 2 parts of acrylic acid at the same time, control the reaction temperature to 200 degrees, and the reaction time is 2 hours. After the reaction, the stainless steel fibers coated with carboxyl groups on the surface are centrifugally separated and purified Obtain hydrophilic carbon-coated stainless steel fibers;

[0037] b. Put methyl cellulose, deionized water and the carbon-coated ...

Embodiment 7

[0044] The conductive concrete prepared according to the ratio of Example 1-Example 6 is tested as follows: Resistivity test: 39mm×45mm stainless steel meshes are respectively installed at both ends of the concrete as conductive electrodes during casting, and a resistance tester is used during the test. The test electrodes are respectively clamped with the electrodes at both ends of the 40mm×40mm×160mm conductive concrete module. After the test value of the resistance tester is stable, read the resistance value, which is the DC resistance R of the conductive concrete. The volume resistivity of conductive concrete is calculated using the formula Q=R(S / L), where S is the electrode area and L is the length of the conductive concrete.

[0045] Flexural strength test: Adjust the two movable supports of the flexural testing machine so that the distance from the center of the lower pressure head of the testing machine is 80 mm, and tighten the two supports. Put the side of the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com