Novel composite aircraft skin material with characteristics of light weight, high strength and high temperature resistance

A technology for aircraft skin and high temperature resistance, which is applied to fuselage bulkheads, layered products, chemical instruments and methods, etc., can solve the problems of high temperature resistance, high price of pure titanium alloy materials, and decreased specific strength, and achieves a solution to the problem. The effect of heat tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

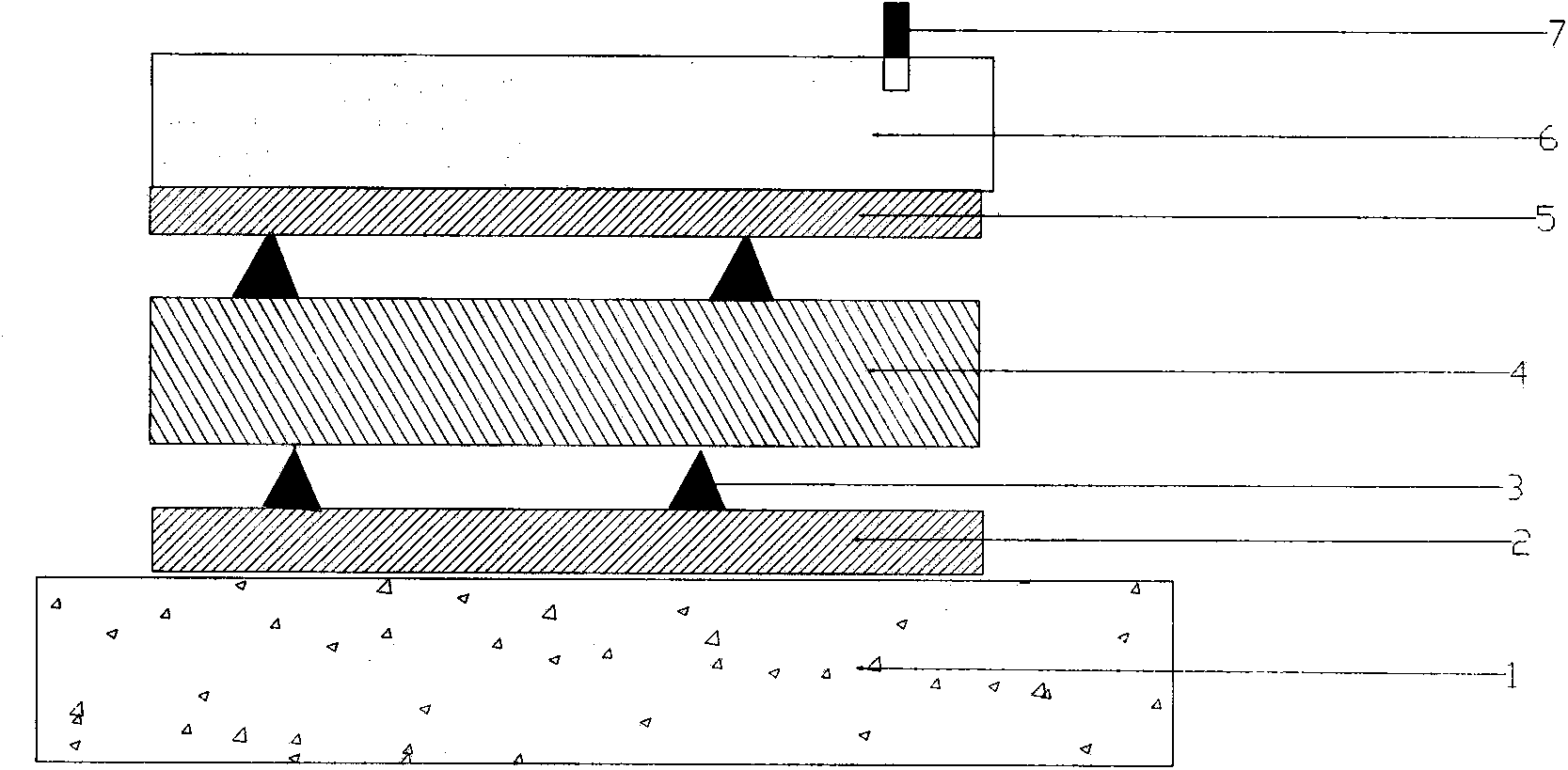

[0016] The material grade of the titanium alloy is Ti-6Al-4V, the thickness is 2mm, and its chemical composition is: aluminum: 5.5%-6.75%, vanadium: 3.5%-4.5%, and the balance is titanium. The material of aluminum alloy is 2024, the thickness is 8mm, the chemical composition of 2024: silicon: 0.5%, iron: 0.5%, copper: 3.8-4.9, manganese: 0.3-0.9, magnesium: 1.2-1.8, chromium: 0.10, zinc: 0.25 , Titanium: 0.15, the balance is aluminum. The charge height of the explosive is 25mm, and the gap is 4mm.

[0017] Among them, the titanium alloy Ti-6Al-4V has a series of advantages such as excellent corrosion resistance, small density, high specific strength, good toughness and weldability. The main alloying elements of aluminum alloy 2024 are Cu, Mg, and Mn, which have high plasticity, fatigue life, fracture toughness and fatigue crack growth resistance, but poor corrosion resistance.

[0018] Specific steps:

[0019] (1) The lightweight, high-strength, high-temperature-resistant c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com