Flexible thermoelectric fiber based on woven P-N type structure and preparation method thereof

A P-N, textile fiber technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, fiber types, etc. Low cost, good breathability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

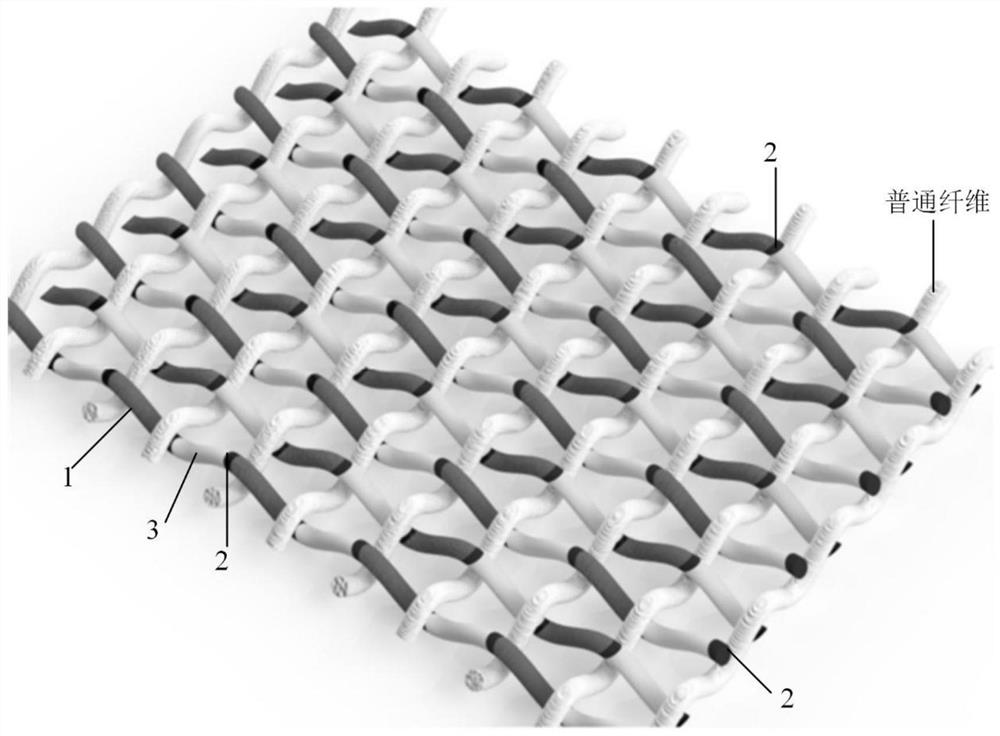

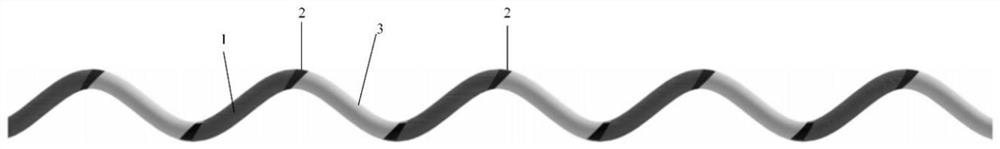

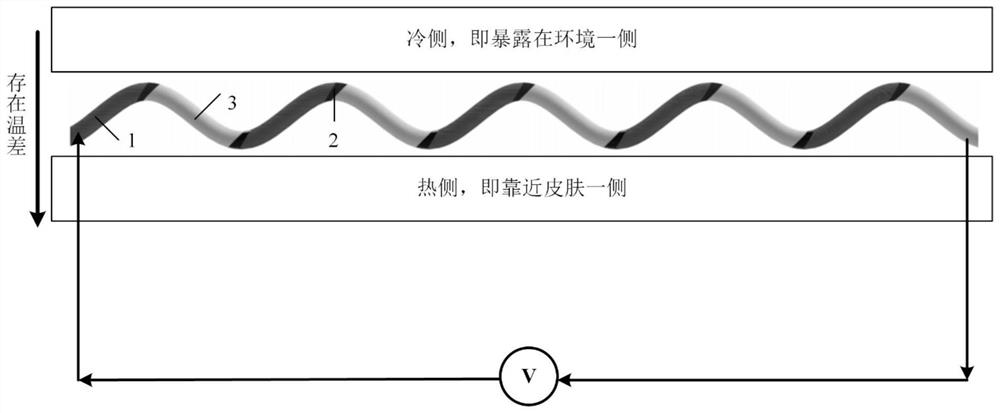

[0042] Such as Figure 1-Figure 4 As shown, a flexible thermoelectric fiber based on a braided P-N structure includes textile fibers, and the textile fibers have a sinusoidal structure, and the peaks or troughs of the sinusoidal structure include P-type thermoelectric regions 1 and N-type thermoelectric regions 3, so A conductive region 2 is provided at the junction of the P-type thermoelectric region 1 and the N-type thermoelectric region 3, and the conductive region 2 is located at the endpoints of the peaks and troughs of the sinusoidal structure.

[0043] The specific preparation method of the flexible thermoelectric fiber described in this embodiment includes the following steps:

[0044] S1. Prepare P-type thermoelectric solution and N-type thermoelectric paste respectively:

[0045] Add dimethyl sulfoxide to the PEDOT:PSS aqueous solution to prepare a P-type thermoelectric solution, and ultrasonically disperse the P-type thermoelectric solution for 30 minutes, and the ...

Embodiment 2

[0052] This example is based on Example 1, which is different from the example in that the specific preparation method of the flexible thermoelectric fiber specifically includes the following steps:

[0053] S1. Prepare P-type thermoelectric solution and N-type thermoelectric paste respectively:

[0054] Add dimethyl sulfoxide to the PEDOT:PSS aqueous solution to prepare a P-type thermoelectric solution, and ultrasonically disperse the P-type thermoelectric solution for 30 minutes. The ambient temperature of the ultrasonic dispersion is 25°C, and the mass fraction of PEDOT:PSS is 100wt %, and the particle size of PEDOT:PSS is 90nm~95nm;

[0055] Add bismuth selenide to polyvinylidene fluoride (PVDF) binder to form N-type thermoelectric paste;

[0056] S2. Soak polyester in deionized water and absolute ethanol in sequence, and perform ultrasonic cleaning for 5 minutes, the ambient temperature of ultrasonic cleaning is 25°C, and the number of cycles is 10;

[0057] S3. Wrap th...

Embodiment 3

[0061] This example is based on Example 1, which is different from the example in that the specific preparation method of the flexible thermoelectric fiber specifically includes the following steps:

[0062] S1. Prepare P-type thermoelectric solution and N-type thermoelectric paste respectively:

[0063] Add ethylene glycol to the PEDOT:PSS aqueous solution to prepare a P-type thermoelectric solution, and ultrasonically disperse the P-type thermoelectric solution for 30 minutes, and the temperature of the ultrasonic dispersion environment is 35°C, wherein the mass fraction of PEDOT:PSS is 100wt%. And the particle size of PEDOT:PSS is 95nm~100nm;

[0064] Add bismuth selenide to polyvinylidene fluoride (PVDF) binder to form N-type thermoelectric paste;

[0065] S2. Soak polyester in deionized water and absolute ethanol in sequence, and perform ultrasonic cleaning for 5 minutes, the ambient temperature of ultrasonic cleaning is 35°C, and the number of cycles is 5 times;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com