Carbon Nanotube Reinforced Aluminum Matrix Composite

A technology for strengthening aluminum-based and composite materials, applied in the field of aluminum-based composite materials, can solve the problems of high cost, ineffective combination, cumbersome processes, etc., and achieve improved tensile strength and wear resistance, low equipment investment, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

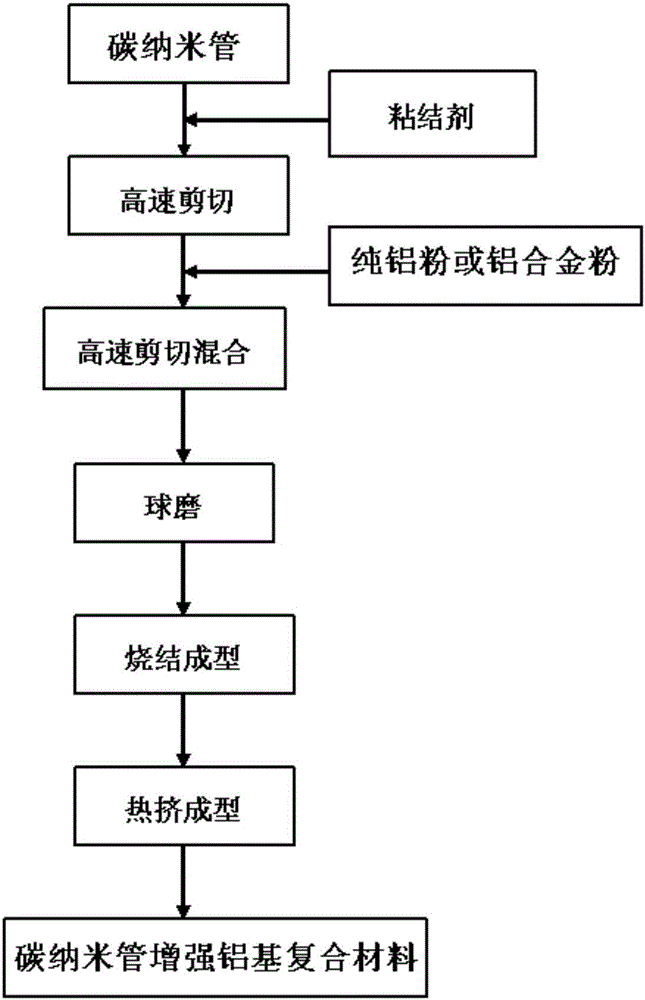

[0028] Such as figure 1 As shown, the preparation of carbon nanotube reinforced aluminum matrix composite material:

[0029] 1) Pre-disperse carboxylated carbon nanotubes with a diameter of 30-50nm in a pulverizer, pulverize at 500 rpm for 10 minutes, add liquid paraffin, and mix with a high-speed shear at 500 rpm for 10 minutes to make liquid paraffin Coated uniformly on the surface of carboxylated carbon nanotubes, and then add pure aluminum powder with a particle size of about 15μm and mix at 500 rpm for 10 minutes, and then take it out, so that the carboxylated carbon nanotubes are evenly distributed on the surface of the pure aluminum powder to obtain the first Composite powder, in terms of weight percentage, the content of each component in the first composite powder is: 1% carboxylated carbon nanotubes, 0.1% liquid paraffin and the balance of pure aluminum powder;

[0030] 2) Put the obtained first composite powder into a ball mill, and take it out after ball milling at 500 ...

Embodiment 2

[0035] Such as figure 1 As shown, the preparation of carbon nanotube reinforced aluminum matrix composite material:

[0036] 1) Pre-disperse the carboxylated carbon nanotubes with a diameter of 30-50nm in a pulverizer, pulverize at 400rpm for 15min, then add stearic acid and mix with a high-speed shearer at 400rpm for 15min to make it hard The fatty acid is evenly coated on the surface of the carboxylated carbon nanotubes, and then pure aluminum powder with a particle size of about 25μm is added and mixed at 400 rpm for 15 minutes, and then taken out, so that the carboxylated carbon nanotubes are evenly distributed on the surface of the pure aluminum powder. The first composite powder, in terms of weight percentage, the contents of the components in the first composite powder are: 5% of carboxylated carbon nanotubes, 0.8% of stearic acid, and the balance of pure aluminum powder;

[0037] 2) Put the obtained first composite powder into a ball mill, and take it out after ball milling...

Embodiment 3

[0041] Such as figure 1 As shown, the preparation of carbon nanotube reinforced aluminum matrix composite material:

[0042] 1) Pre-disperse the carboxylated carbon nanotubes with a diameter of 30-50nm in a pulverizer, pulverize at 300rpm for 20min, then add polyvinylpyrrolidone and mix with a high-speed shearer at 300rpm for 20min to make the polymer Vinylpyrrolidone is uniformly coated on the surface of the carboxylated carbon nanotubes, and then pure aluminum powder with a particle size of about 25μm is added and mixed at 300 rpm for 20 minutes, and then taken out, so that the carboxylated carbon nanotubes are evenly distributed on the surface of the pure aluminum powder. The first composite powder, in terms of weight percentage, the contents of the components in the first composite powder are: 6% of carboxylated carbon nanotubes, 2% of polyvinylpyrrolidone, and the balance of pure aluminum powder;

[0043] 2) Put the obtained first composite powder into a ball mill, and take it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com