Formula of paraffin adhesive for bonding special ceramics and iron plate

A technology of special ceramics and adhesives, applied in the direction of adhesives, wax adhesives, adhesive types, etc., can solve problems such as lack of bonding performance, poor permeability, and risky processing, and achieve excellent bonding effects , fast condensation at room temperature, and the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] High-temperature high-purity paraffin 560 High-purity rosin 160

[0026] Polyethylene glycol 30 Synthetic resin 30

[0027] Sibutramine intermediate 100 Curing accelerator 120

Embodiment 2

[0029] High-temperature high-purity paraffin 564 High-purity rosin 162

[0030] Polyethylene glycol 30 Synthetic resin 30

[0031] Sibutramine Intermediate 98 Curing Accelerator 116

Embodiment 3

[0033] High-temperature high-purity paraffin 570 High-purity rosin 165

[0034] Polyethylene glycol 30 Synthetic resin 30

[0035] Sibutramine intermediate 95 Curing accelerator 110

[0036] High-temperature high-purity paraffin wax refers to paraffin wax with a purity of 99.5% above 80 degrees Celsius, high-purity rosin refers to rosin with a purity of 95% or more, synthetic resins mainly use phenolic synthetic resins, and curing accelerators mainly refer to resin curing accelerators.

[0037] The production process of the present invention is as follows: ingredients (all materials are evenly mixed and placed in the container) → 300 ° C electric furnace is heated to 135 ° C (during the furnace stirring) → heat preservation for about 5 hours (during the furnace stirring) → take out and stir after heat preservation, After cooling to about 90°C, pour into the mold → cooling and forming.

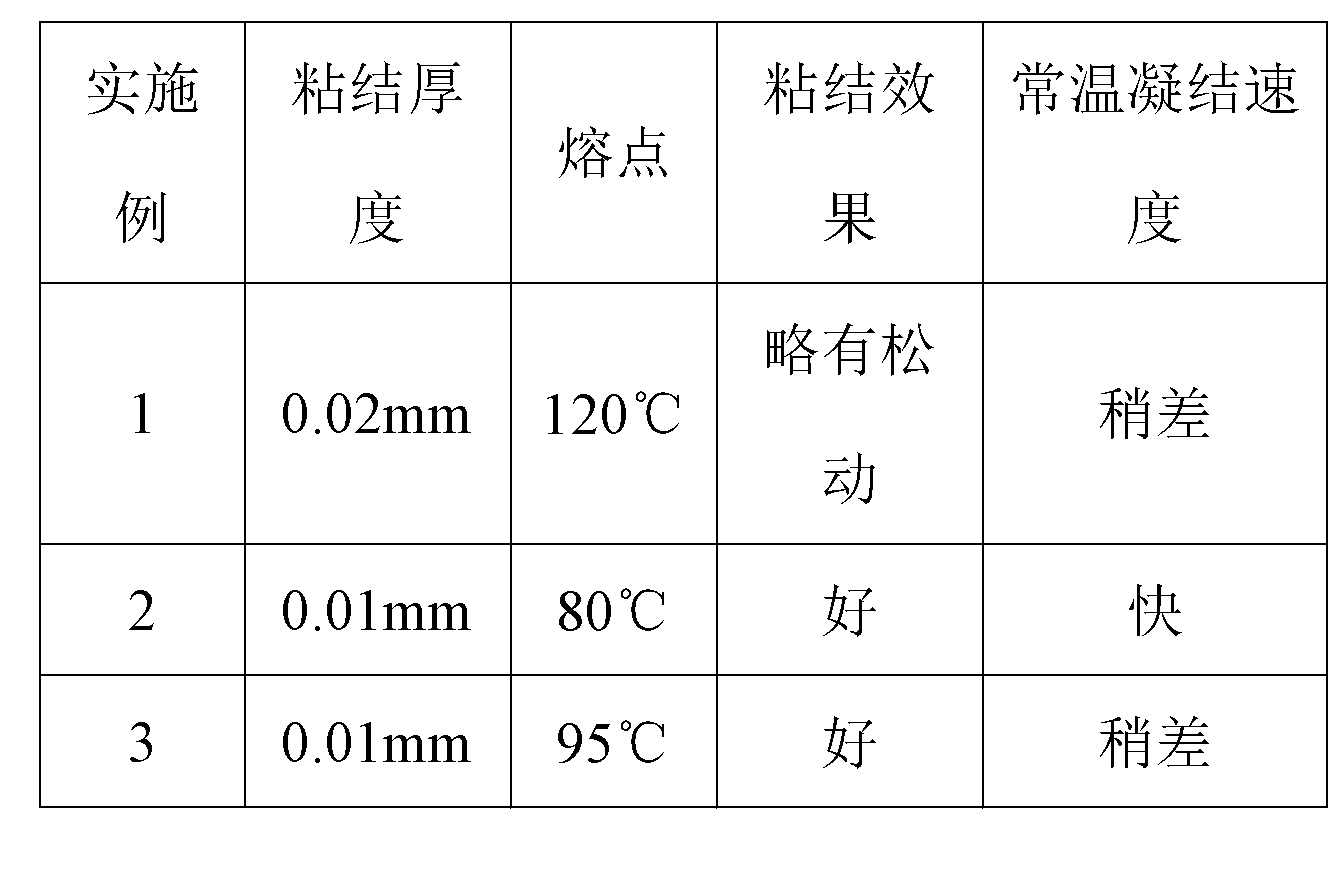

[0038] Result comparison:

[0039]

[0040] In summary, the formula ratio of embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com