Method for processing coiled BOPP film adhesive tape

A processing method and adhesive tape technology, applied in the direction of film/flaky adhesives, adhesives, etc., can solve problems such as large noise, uneven bonding, and uneven bonding on the surface of the tape film, so as to reduce noise, Uniform bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below.

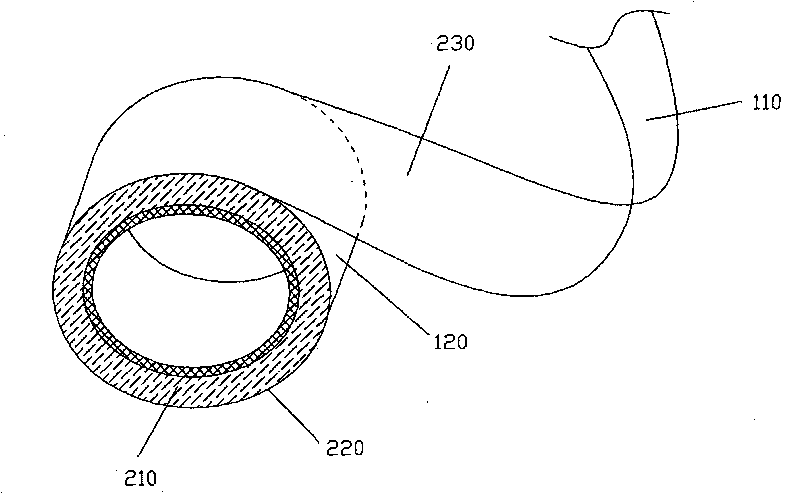

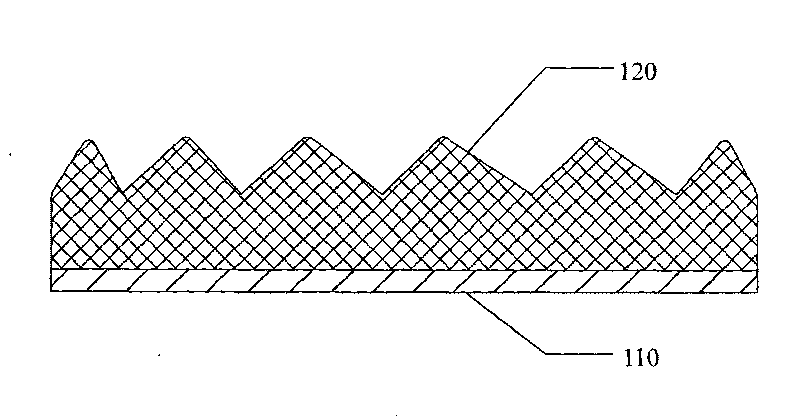

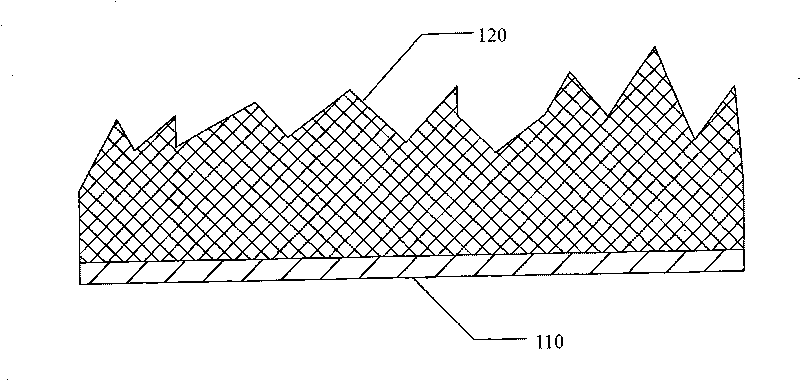

[0016] Such as figure 1 As shown, according to the processing method of the present invention, in the bonding and winding step of the roll-type BOPP film adhesive tape 210, the surface structure of the adhesive tape 120 to be bonded is first carried out to uniformize the surface structure, so that the adhesive tape 210 The surface tension of the surface to be bonded 120 is 35-45 dynes, and its most preferred range is 38-40 dynes.

[0017] The homogenization treatment of the surface structure can adopt flame heating treatment or corona treatment. When carrying out the fire-baking operation, the film can advance according to the normal production process speed, and a fire-baking part with flame or without flame is installed to homogenize the surface structure of the lower adhesive tape 220 .

[0018] When corona treatment is used, corona treatment is a kind of electric shock treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com