A new large-scale method for preparing silver-containing inorganic antibacterial masterbatches for highly transparent plastics

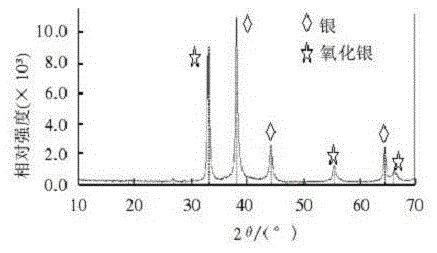

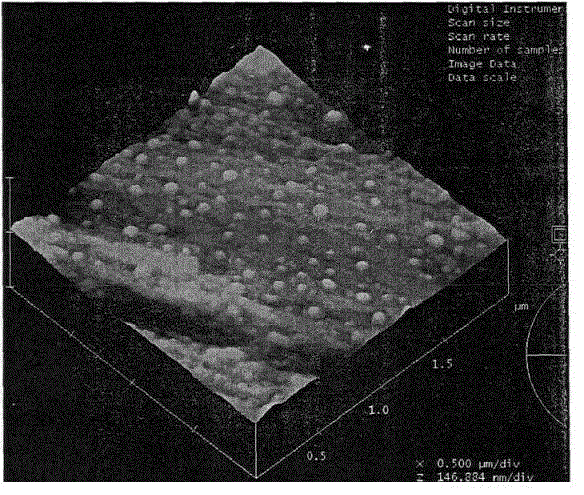

A large-scale preparation and antibacterial masterbatch technology, which is applied in the field of plastics, can solve the problems of large loaded nano-silver particles, large particle size, and inability to meet the actual requirements of high-transparency plastics, and achieve stable appearance and color, and disperse and protect silver particles. The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Preparation of silver-containing inorganic antibacterial masterbatch of the present invention

[0079] Add 0.2 parts by weight of high silver oxide ultrafine powder, 99 parts by weight of PMMA resin, 1 part by weight of composite dispersant (PVPk30 / AClyn201A=1:2), and 0.5 parts by weight of pentaerythritol into the high-speed mixer produced by Zhangjiagang Chuangjia Machinery Co., Ltd. , carry out high-speed mixing and stirring treatment at 1000rpm for 4 minutes to fully knead evenly, and then put it into a large-capacity devolatilization twin-screw extruder produced by Nanjing Lixuan Machinery Equipment Co., Ltd. to melt and extrude at high temperature to obtain granules. Silver-containing inorganic antibacterial masterbatch. The length-to-diameter ratio of the screw is 56:1, the processing temperature is 260-270°C, and the screw speed is 100rpm.

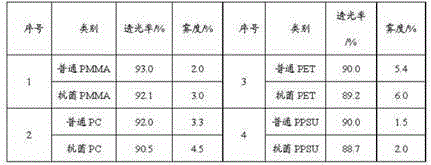

[0080] Using the PMMA antibacterial masterbatch prepared in this example, the method described in this manua...

Embodiment 2

[0081] Example 2: Preparation of silver-containing inorganic antibacterial masterbatch of the present invention

[0082] Add 1.0 parts by weight of silver citrate, 95 parts by weight of PC resin, 3 parts by weight of composite dispersant (PVPk90 / sarin resin 8920=1:2), and 1.0 parts by weight of pentaerythritol stearate into Zhangjiagang Chuangjia Machinery Co., Ltd. In the high-speed mixer produced by the company, high-speed mixing and stirring treatment was carried out at 1500rpm for 3 minutes to fully mix and evenly mix, and then put into a large-capacity devolatilization twin-screw extruder produced by Nanjing Lixuan Machinery Equipment Co., Ltd. for high-temperature melt extrusion Granules to obtain the silver-containing inorganic antibacterial masterbatch. The length-to-diameter ratio of the screw is 56:1, the processing temperature is 270-300°C, and the screw speed is 120rpm.

[0083] Using the PC antibacterial masterbatch prepared in this example, use the method desc...

Embodiment 3

[0084] Example 3: Add 2.0 parts by weight of silver behenate, 96 parts by weight of PC resin, 2.5 parts by weight of composite dispersant (PVPk30 / AClyn295A=1:2), and 1.0 parts by weight of pentaerythritol phosphate into the high-speed mixing machine produced by Zhangjiagang Chuangjia Machinery Co., Ltd. In the machine, carry out high-speed mixing and stirring treatment at 800rpm rotating speed for 4min to fully mix and evenly, and then put it into a reaction type twin-screw extruder produced by Lanzhou Lantai Plastic Machinery Co., Ltd. to melt and extrude at high temperature to obtain granulation. Silver inorganic antibacterial masterbatch. The length-to-diameter ratio of the screw is 58:1, the processing temperature is 260-280°C, and the screw speed is 90rpm.

[0085] Using the PET antibacterial masterbatch prepared in this example, use the method described in this manual to detect, and add the antibacterial samples Escherichia coli (ATCC25922) and Staphylococcus aureus (A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com