Air compressor oil compounding agent, preparation method of air compressor oil compounding agent and air compressor oil composition

A technology of air compressor and oil compounding agent, applied in lubricating compositions, additives, petroleum industry and other directions, can solve the problems of adverse effects of oil demulsibility, increase oil residue carbon and ash value, etc., and achieve excellent oxidation Stability, good performance, good effect of oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the ashless air compressor oil compounding agent of the present invention comprises: sequentially adding required additive components into a stirring container in proportion, and stirring at 20-60° C. until uniform and transparent.

[0036] The present invention also provides an air compressor oil composition, which includes base oil and the ashless air compressor oil compound of the present invention, and the ashless air compressor oil compound accounts for 0.8% to 3% by weight of the substance, preferably 1.2% to 1.8% by weight.

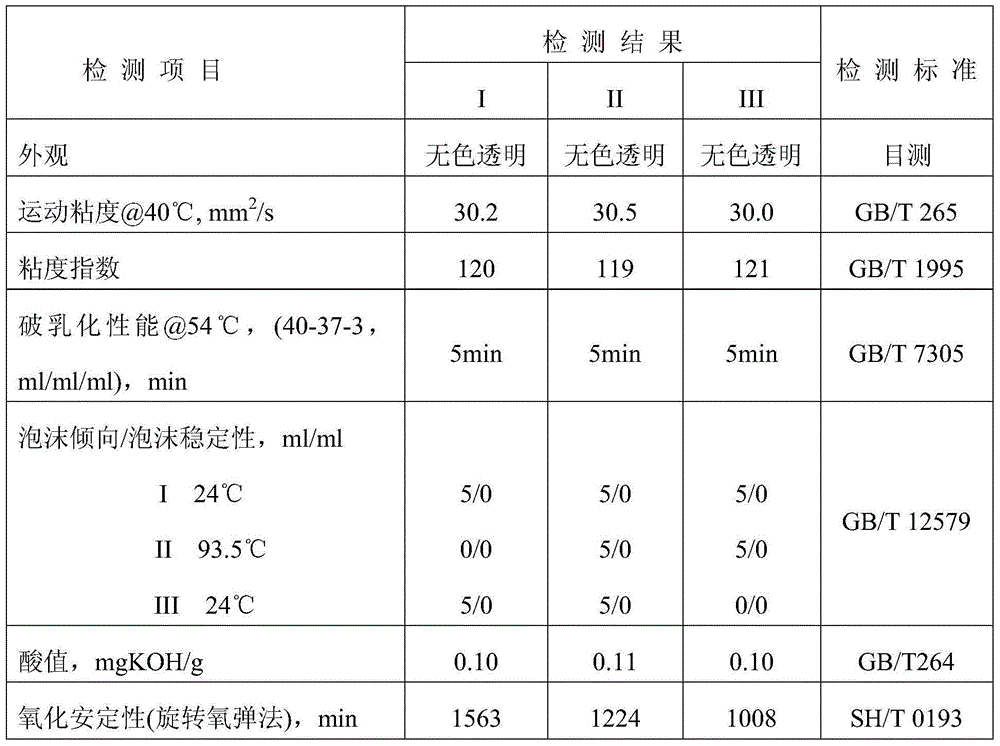

Embodiment 1

[0040] Get 70 parts by weight of sulfur compound methylene bis-dibutyl dithiocarbamate Vanlube7723 (R.T.VanderbiltCompany, Inc. the same below), 16 parts by weight of phenolic antioxidant L135 (BasfChemicalCompany, the same below), 6.7 parts by weight Benzotriazole derivatives T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below) as the metal deactivator, 0.3 parts by weight of methyl silicone oil T901 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below) as the antifoaming agent ), 0.2 parts by weight of propylene oxide / ethylene oxide block copolymer Lubrizol 5957 (Lubrizol Corporation, the same below) and 6.8 parts by weight of PAO6 base oil (INEOSGroup, the same below) as a demulsifier were added to the blender, and started at 50 ° C Stir until the mixture is completely dissolved, uniform and transparent, and ashless strong anti-oxidation air compressor oil compound I is obtained. Comparative example 1

Embodiment 2

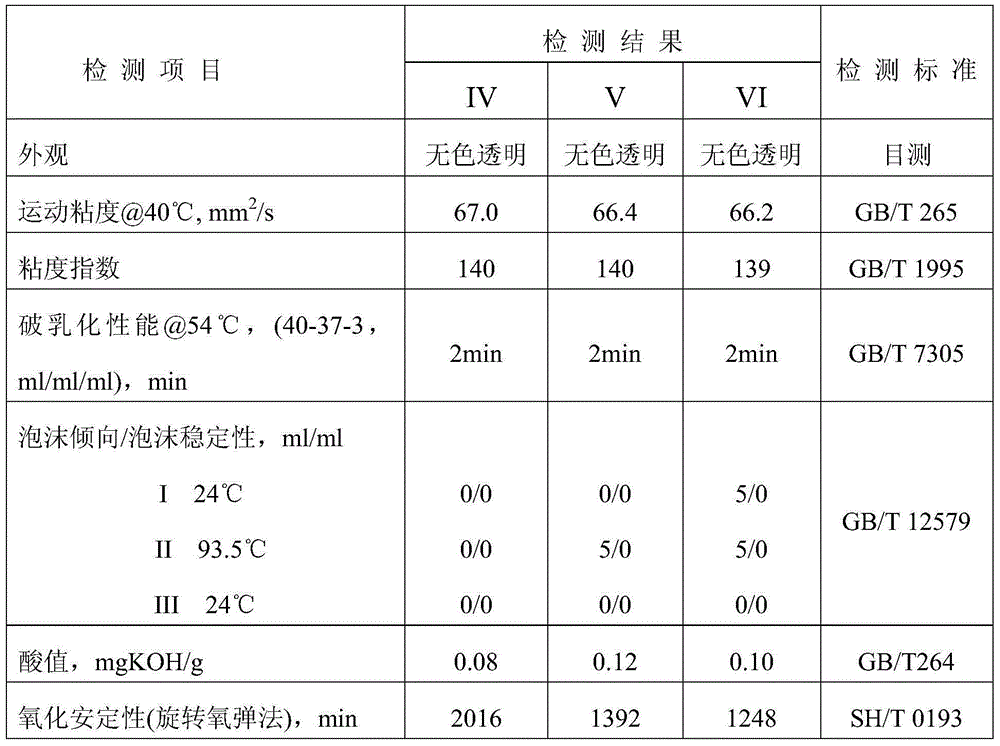

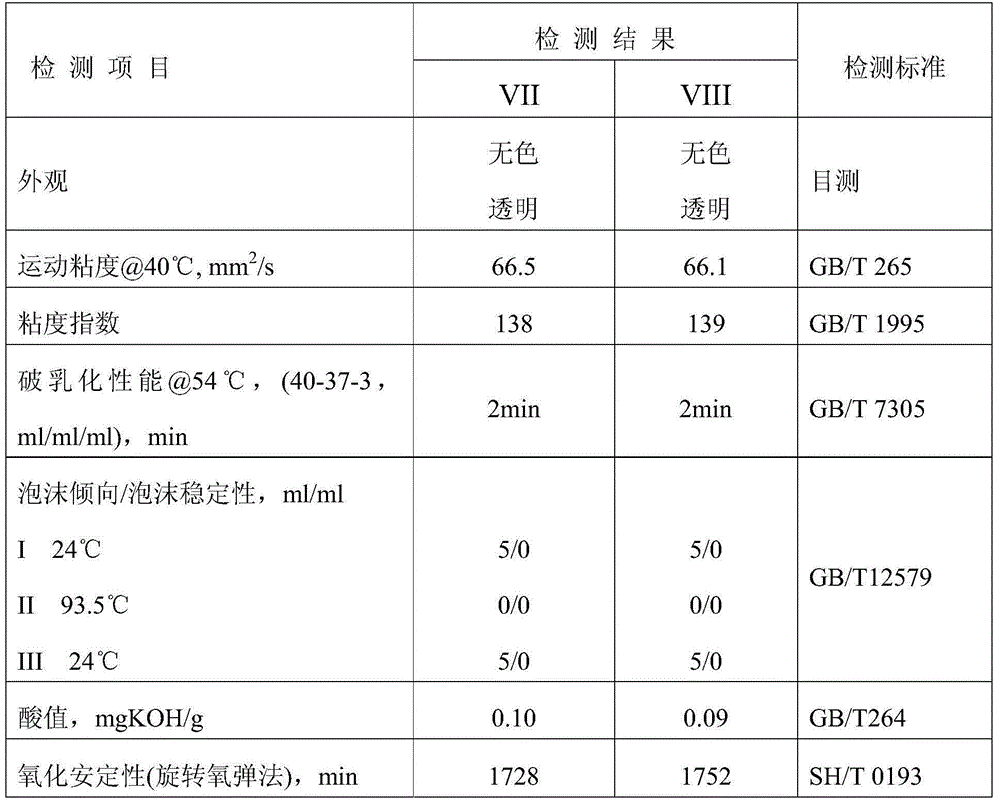

[0045] Get 60 parts by weight of sulfur compound methylene bis-dibutyl dithiocarbamate Vanlube7723, 28 parts by weight of phenolic antioxidant L135, 6 parts by weight of benzotriazole derivatives T551 as metal deactivators, 0.2 Parts by weight of methyl silicone oil T901 as an antifoaming agent, 0.5 parts by weight of propylene oxide / ethylene oxide block copolymer Lubrizol5957 as a demulsifier, and 5.3 parts by weight of PAO6 base oil are added to the blending tank, and stirring is started at 50 ° C Until the mixture is completely dissolved, uniform and transparent, the ashless type strong anti-oxidation air compressor oil compound IV is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com