Low-chlorine environment-friendly PAE wet strength agent and synthesis method thereof

A technology of PAE wet strength agent and synthesis method, which is applied in the direction of reinforcement addition, special paper, non-fiber pulp addition, etc., can solve the problems of unoptimistic toxicity, environmental pollution, health damage, etc., and achieve stable appearance and color and excellent wetness. Intensity, effect of high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

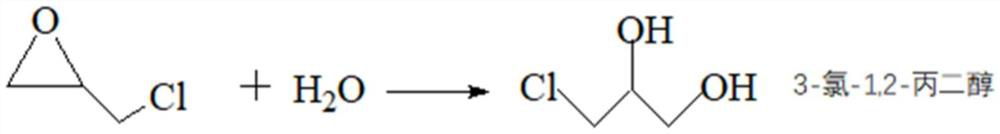

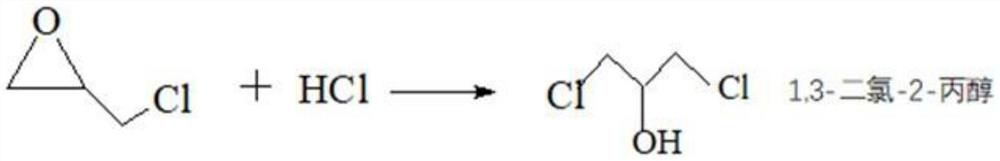

Method used

Image

Examples

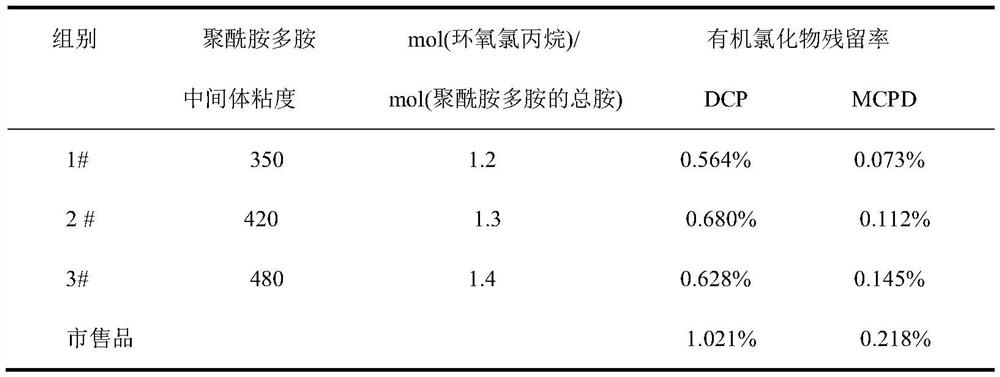

Embodiment 1

[0031] Weigh 146 grams of adipic acid (1.0mol) and 50 grams of deionized water into a four-necked flask, stir to form a slurry, and then feed nitrogen after vacuuming, then add 104 grams of diethylenetriamine (1.01mol) in sequence, and heat up by electric heating Heat it at 180°C for 2 hours, collect about 86.5 grams of water released during the reaction, and add 215 grams of deionized water to obtain a polyamide intermediate with a solid content of 50%, a viscosity of 340 cps, and a pH of 10.2.

[0032] 100 grams (0.232 mol) of the above-mentioned polyamide aqueous solution, 50 grams of deionized water, 0.2 g of triethanolamine, and 1.0 g of potassium carbonate were heated to 25 ° C during the stirring process, and 26 grams (0.281 mol) of epichlorohydrin was added dropwise. The dripping time is 2 hours. During the whole dripping process of epichlorohydrin, potassium carbonate solution needs to be continuously added to control the pH of the reactant in the kettle to be above 9....

Embodiment 2

[0034] Weigh 146 grams of adipic acid (1.0 mol) and 80 grams of deionized water into a four-neck flask, stir to form a slurry, vacuumize and feed nitrogen, then add 99 grams of diethylenetriamine (0.96 mol) in turn, and heat up by electric heating Heat it at 175°C for 2 hours, collect about 115 grams of water released during the reaction, add 210 grams of distilled water to obtain a polyamide intermediate with a solid content of 50%, a viscosity of 420 cps, and a pH of 9.7.

[0035] With 100 grams (0.228mol) of the above-mentioned polyamide aqueous solution, 65 grams of deionized water, 0.2 g of hexamethylenetetramine, and 1.0 g of sodium carbonate, the temperature was raised to 25 ° C during the stirring process, and 28 grams of epichlorohydrin ( 0.303mol), the dropping time is 2h. During the whole epichlorohydrin dripping process, sodium carbonate solution needs to be continuously added to control the pH of the reactant in the kettle to be above 9.5. After the end of epichlor...

Embodiment 3

[0037] Weigh 146 grams of adipic acid (1.0mol) and 120 grams of deionized water and add them to a four-necked flask, stir to form a slurry, vacuumize and feed nitrogen, then add 102 grams of diethylenetriamine (0.99mol) and heat up to 180°C, keep warm for 2.0 hours, collect about 137 grams of water released during the reaction, add 212 grams of distilled water to obtain a polyamide intermediate, and its indicators are 50% solid content, 480 cps viscosity, and 9.8 pH.

[0038]With 100 grams (0.228mol) of the above-mentioned polyamide aqueous solution, 80 grams of deionized water, 0.6 g of hexamethylenetetramine, and 1.0 g of sodium carbonate, the temperature was raised to 25 ° C during the stirring process, and 30 grams of epichlorohydrin ( 0.324mol), and the dropping time is 2h. During the whole epichlorohydrin dripping process, sodium carbonate solution needs to be continuously added to control the pH of the reactant in the kettle to be above 9.5. After 30 minutes of epichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com