Method for rapidly and mildly extracting heavy metals from cereals

A technology of heavy metals and heavy metal ions, which is applied in the field of chemical separation, can solve the problems of strong corrosive acids and oxidizing reagents, difficulty in adapting to rapid detection, and increased safety hazards for operators, so as to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A quick and gentle extraction method for lead in grains, the steps are:

[0035] (1) Take 500g each of rice, wheat, and corn. After the rice is hulled, the three raw materials are crushed by a pulverizer to form a powder sample with a particle size of 0.2mm;

[0036] (2) Weigh 0.2g of each sample in (1), add 2% nitric acid 2-5mL, shake vigorously or place it on a vortex for 15min;

[0037] (3) Let stand for 10 minutes, and take the supernatant for testing;

[0038] (4) Graphite furnace atomic absorption detection is used, and lead standard curve drawing and sample detection are carried out according to the heating program in Table 1.

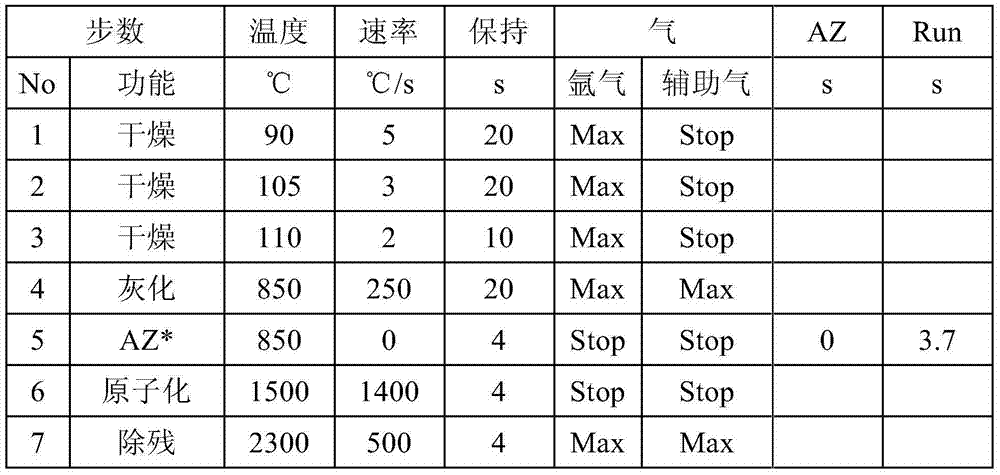

[0039] Table 1 Graphite furnace heating program (lead)

[0040]

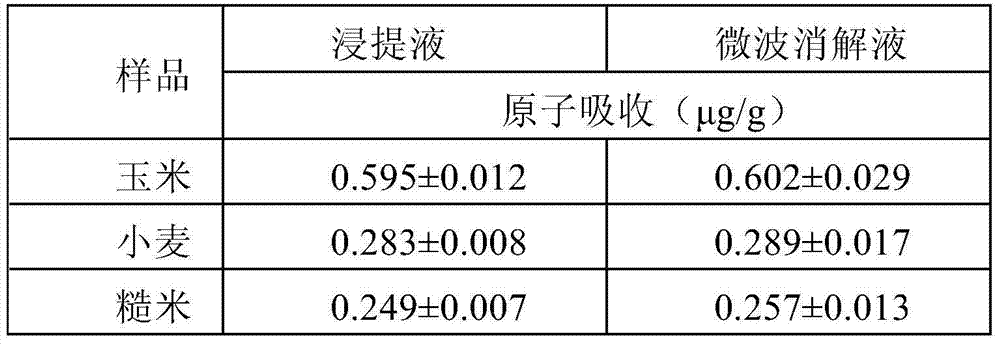

[0041] Comparing the detection results with the results obtained by the microwave digestion method showed that there was no significant difference between the two detection results (p<0.1) (see Table 2).

[0042] Table 2 Comparison of lead content detected by this method and microwave ...

Embodiment 2

[0045] A quick and gentle extraction method for cadmium in grains, the steps are:

[0046] (1) Take 500g each of rice, wheat, and corn. After the rice is hulled, the three raw materials are crushed by a pulverizer to prepare a powder sample with a particle size of 0.5mm;

[0047] (2) Weigh 0.2g each of the samples in (1), add 6ml of 2% nitric acid, and shake for 1min;

[0048] (3) Centrifuge the sample in (2) at 12000 rpm for 5 minutes, and take the supernatant for testing;

[0049] (4) Graphite furnace atomic absorption test is used, and the standard curve of cadmium is drawn and the sample is tested according to the heating program in Table 3;

[0050] Table 3 Graphite furnace heating program (cadmium)

[0051]

[0052] Comparing the test results with the microwave digestion samples showed that there was no significant difference between the two test results (p<0.1) (see Table 4).

[0053] Table 4 Comparison of cadmium content detected in this embodiment and microwave digestion

[0054] ...

Embodiment 3

[0056] Cadmium, lead, manganese, copper, zinc, strontium, and arsenic in grains can be quickly and gently extracted and detected at the same time. The steps are:

[0057] (1) Take 500g each of rice, wheat, corn, rice, and flour. The rice is hulled and crushed by a pulverizer to make a powder sample with a particle size of 0.25 mm;

[0058] (2) Weigh 0.2 g of each sample obtained in (1), add 5 mL of 5% nitric acid, mix well and shake;

[0059] (3) Centrifuge the sample obtained in (2) at 12000 rpm for 5 minutes, take the supernatant, and dilute it by 5 times before testing;

[0060] (4) Control group Weigh 0.2g sample into the digestion tube, add 5mL nitric acid and 2mL hydrogen peroxide, and digest according to the microwave digestion method. After digestion, the acid is rushed to near dryness, and the volume is set to 25mL as the control value.

[0061] (5) The supernatant was detected by ICP-MS. ICP-MS instrument parameters are: incident power: 1500V; Torch-H: -0.3mm; Torch-V: -0.4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com