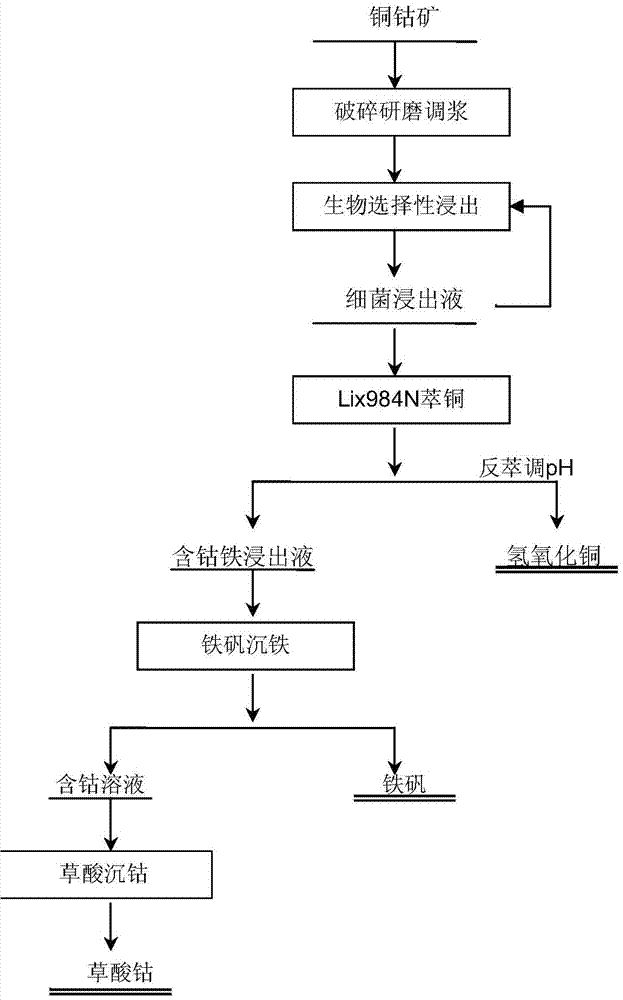

Biological selectivity leaching method of low-grade copper-cobalt ore

A low-grade and selective technology, applied in the field of microbial metallurgy, can solve the problems of loss of cobalt, difficult enrichment and recovery of cobalt, lack of cobalt recovery system, etc., and achieve the effect of short process flow, efficient recovery and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) The low-grade copper-cobalt ore is crushed and ground to a particle size ≤74μm, accounting for 50% of the total flotation concentrate; the copper-cobalt ore is 0.05% cobalt content and 10.00% copper content. Copper exists in the form of chalcopyrite, and cobalt exists in the form of sulphur cobalt.

[0021] (2) The mixed bacterial liquid containing Microspirillum ferrooxidans, Thiobacillus ferrooxidans and Thiobacillus acidophilus is inoculated into 9K medium in an oxidation tank equipped with a stirring device for cultivation. The amount of inoculation is based on the volume ratio: culture medium=1:10, aerated and stirred, aerated amount of 0.1 m 3 / h, the stirring rate is 600 rpm, the culture temperature is 44°C, the pH value of the culture solution is 1.0, and the culture time is 24 hours.

[0022] (3) Add the copper-cobalt ore to the bacterial culture solution to make the mass concentration of the ore powder 25%, fill with air and stir, and the aeration volume is 0.1...

Embodiment 2

[0027] (1) The copper-cobalt ore is crushed and ground to a particle size ≤74μm, accounting for 65.4% of the total flotation concentrate; the copper-cobalt ore contains 2% cobalt and 18.00% copper, of which copper is It exists in the form of chalcopyrite, and cobalt exists in the form of sulphur copper cobalt.

[0028] (2) The mixed bacterial liquid containing Microspirillum ferrooxidans, Thiobacillus ferrooxidans and Thiobacillus acidophilus is inoculated into 9K medium in an oxidation tank equipped with a stirring device for cultivation. The volume ratio of inoculation is as follows: strain: culture medium=1:15, aerated and stirred, aerated amount is 0.2m 3 / h, the stirring rate is 1000 revolutions per minute, the culture temperature is 52°C, the pH value of the culture solution is 1.5, and the culture time is 24 hours.

[0029] (3) Add copper-cobalt ore to the bacterial culture solution to make the mass concentration of ore powder 20%, inflate and stir with air, the aeration vol...

Embodiment 3

[0034] (1) The copper-cobalt ore is crushed and ground to a particle size ≤74μm, accounting for 78% of the total flotation concentrate; the copper-cobalt ore contains 1.05% cobalt and 25% copper, of which copper is It exists in the form of chalcopyrite, and cobalt exists in the form of arsenite.

[0035] (2) The mixed bacterial liquid containing Microspirillum ferrooxidans, Thiobacillus ferrooxidans and Thiobacillus acidophilus is inoculated into 9K medium in an oxidation tank equipped with a stirring device for cultivation. The volume ratio of inoculation is as follows: strain: culture medium=1:20, aerated and stirred, aerated amount 0.3m 3 / h, the stirring rate is 1400 revolutions per minute, the culture temperature is 60°C, the pH value of the culture solution is 2.0, and the culture time is 24 hours.

[0036] (3) Add the copper-cobalt ore to the bacterial culture solution to make the mass concentration of the ore powder 18%, fill with air and stir, and the aeration volume is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com