Measuring method for cobalt content in lining paper of cigarette

A cigarette lining paper and a measurement method technology, which are applied in the preparation of test samples, measuring devices, material analysis by electromagnetic means, etc. The effect of matrix interference, good sensitivity and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the detection method of cobalt content in the inner lining paper for cigarettes is as follows (the flow chart of the detection method is as follows figure 1 shown)

[0035] 1. Sample pretreatment: The preparation method of the sample solution specifically includes weighing 0.2315g (accurate to 0.0001g) of the cigarette lining paper sample into a microwave digestion tank, adding 5mL nitric acid, 1.5mL hydrogen peroxide, and 2mL hydrogen peroxide respectively. Hydrofluoric acid, after standing for 10 minutes, slowly add 1.0mL of hydrochloric acid, after standing for 10 minutes, microwave digestion under ultra-high pressure conditions, the digestion procedure is shown in Table 1. After the digestion, take out the digestion tank, cool to room temperature, slowly open the lid, heat at 125°C to remove the acid to about 0.50mL, transfer to a 50mL plastic volumetric flask, wash the digestion tank repeatedly with ultrapure water, and wash the solution togethe...

Embodiment 2

[0057] The difference with Example 1 is:

[0058] 1. Pretreatment of samples: Weigh 0.25-0.30g (accurate to 0.0001g) of cigarette lining paper samples into a microwave digestion tank, add 6mL nitric acid, 1mL hydrogen peroxide, 2.5mL hydrofluoric acid, and let stand for 10min After that, 0.5 mL of hydrochloric acid was slowly added. After the digestion, heat the acid at 130°C to about 1.0mL.

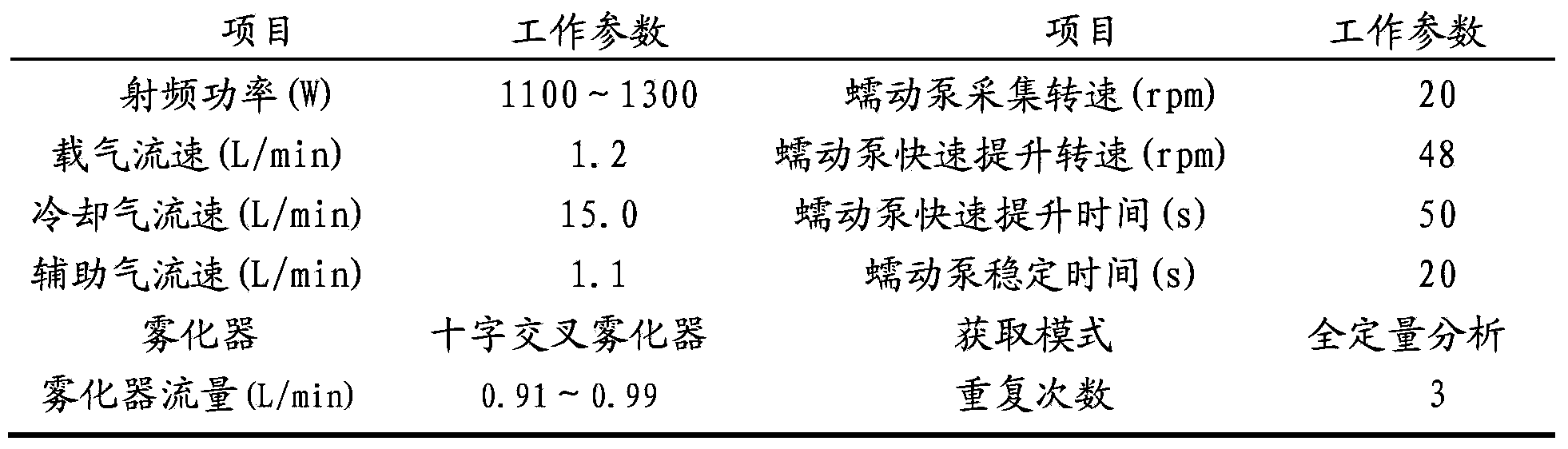

[0059] 2. Measurement method Instrument working conditions: RF power 1200W, atomizer flow rate 0.96L / min.

[0060] 3. Others are the same as in Example 1.

[0061] 4. Measure the standard blank solution of cobalt, the cobalt standard series solution, the blank sample solution, and the inner lining paper sample solution for cigarettes according to the instrument working conditions of the "measurement method" item of the present embodiment, and obtain the working curve regression equation: Y=0.5962 +0.0233, correlation coefficient R 2 : 0.99994, convert the content of cobalt in the inn...

Embodiment 3

[0065] The difference with embodiment 1 is:

[0066] 1. The microwave digestion program is shown in Table 6:

[0067] Table 6 Microwave digestion program of inner lining paper for cigarettes

[0068]

[0069]

[0070] 5. Determination method Instrument working conditions: RF power 1300W, atomizer flow rate 0.94L / min.

[0071] 2. Others are all the same as in Example 1.

[0072] 3. Measure the standard blank solution of cobalt, the cobalt standard series solution, the blank sample solution, and the inner lining paper sample solution for cigarettes according to the instrument working conditions of the "measurement method" item of the present embodiment, and obtain the working curve regression equation: Y=0.5648 +0.1126, correlation coefficient R 2 : 0.99997, convert the content of cobalt in the inner lining paper for cigarettes by the result calculation formula, measure 12 # The content of cobalt in the lining paper for cigarettes is 0.39ug / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com