Method for performing purified smelting on high-temperature alloy return material by using yttrium oxide crucible

A high-temperature alloy, yttrium oxide technology, applied in the field of vacuum induction melting, can solve the problems of poor chemical stability of magnesium oxide, easy slag formation of acid oxides, and reduced gas element content, so as to reduce the possibility of oxygen supply and high stability. , The effect of easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

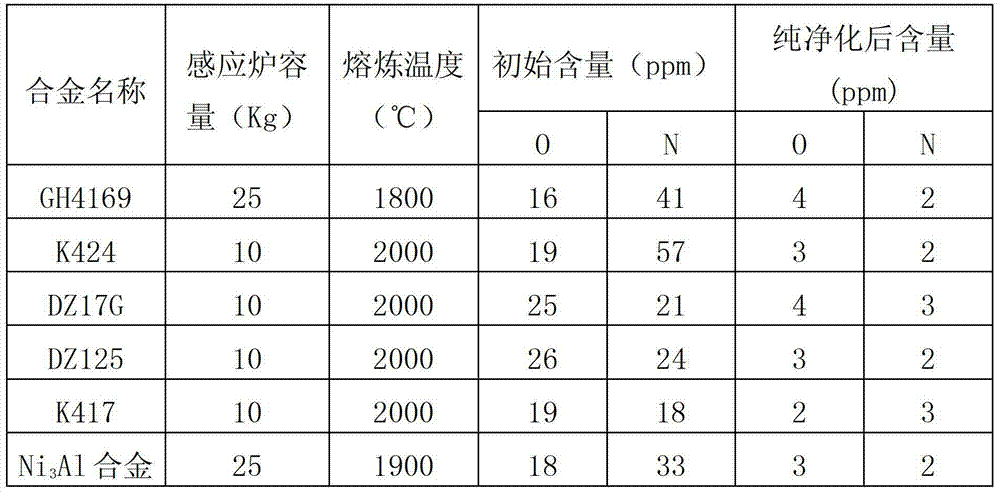

Embodiment 1

[0042] A method for purifying and smelting 25Kg of GH4169 alloy riser return material by using an yttrium oxide crucible, the steps of the method are charging→purifying smelting→casting molding.

[0043] The mass percent of the GH4169 alloy return material is: C is 0.03%, Cr is 18.3%, Ni is 52.7%, Mo is 3.18%, Al is 0.45%, Ti is 1.02%, Nb is 5.26%, Fe is more than quantity.

[0044] The specific purification and smelting steps are:

[0045] Step 1: Install the yttrium oxide crucible and the fully preheated ingot mold in the vacuum induction melting furnace, clean the crucible and ingot mold, and install the yttrium oxide ceramic filter on the sprue cup;

[0046] Ingot mould: put the steel ingot mold into the resistance furnace and raise the temperature to 900°C, keep it warm for 4 hours, and put the fully preheated ingot mold into the vacuum induction furnace casting chamber for pouring;

[0047] Cleaning of the yttrium oxide crucible and ingot mold: Use a dust collector to ...

Embodiment 2

[0058] A method for purifying and smelting 10Kg of K424 alloy sprue return material by using an yttrium oxide crucible, the steps of the method are charging→purifying smelting→casting molding.

[0059] The mass percent of the K424 alloy return material is: C is 0.15%, Cr is 9.7%, Co is 13.6%, W is 1.5%, Mo is 3.1%, Al is 5.2%, Ti is 4.4%, and Nb is 0.8% %, V is 0.7%, B is 0.015%, Zr is 0.02%, Ce is 0.02%, and Ni is the balance.

[0060] Step 1: Install the yttrium oxide crucible and the fully preheated ingot mold in the vacuum induction melting furnace, clean the crucible and ingot mold, and install the yttrium oxide ceramic filter on the sprue cup;

[0061] Ingot mould: Put the graphite mold shell into the molding sand box for molding, then put it into the resistance furnace and heat it up to 600°C for 2 hours, and then put the fully preheated ingot mold into the casting chamber of the vacuum induction furnace for pouring;

[0062] Cleaning of the yttrium oxide crucible and ...

Embodiment 3

[0073] Use yttrium oxide crucible to 25Kg Ni 3 The invention discloses a method for purifying and smelting the returned materials of Al alloy waste castings, and the steps of the method are charging→purifying and smelting→casting molding.

[0074] Said Ni 3 The mass percentage of the Al alloy return material is: Mo is 14.3%, Al is 7.8%, and Ni is the balance.

[0075] Step 1: Install the yttrium oxide crucible and the fully preheated ingot mold in the vacuum induction melting furnace, clean the crucible and the ingot mold, and install an alumina ceramic filter on the sprue cup;

[0076] Ingot mould: Put the yttrium oxide mold shell into the molding sand box for molding, then put it into a resistance furnace and heat it up to 900°C for 2 hours, and then put the fully preheated ingot mold into the casting chamber of the vacuum induction furnace for pouring;

[0077] Cleaning of the yttrium oxide crucible and ingot mold: Use a dust collector to clean the inner wall of the yttri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com