Preparation method of low-viscosity microcapsule-wrapped APP (ammonium polyphosphate)

An ammonium polyphosphate and microcapsule technology, applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of poor flame retardant durability, poor fluidity, and thorn-like powder, and achieve excellent results. The effect of flowability and compatibility, excellent electrical properties, average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

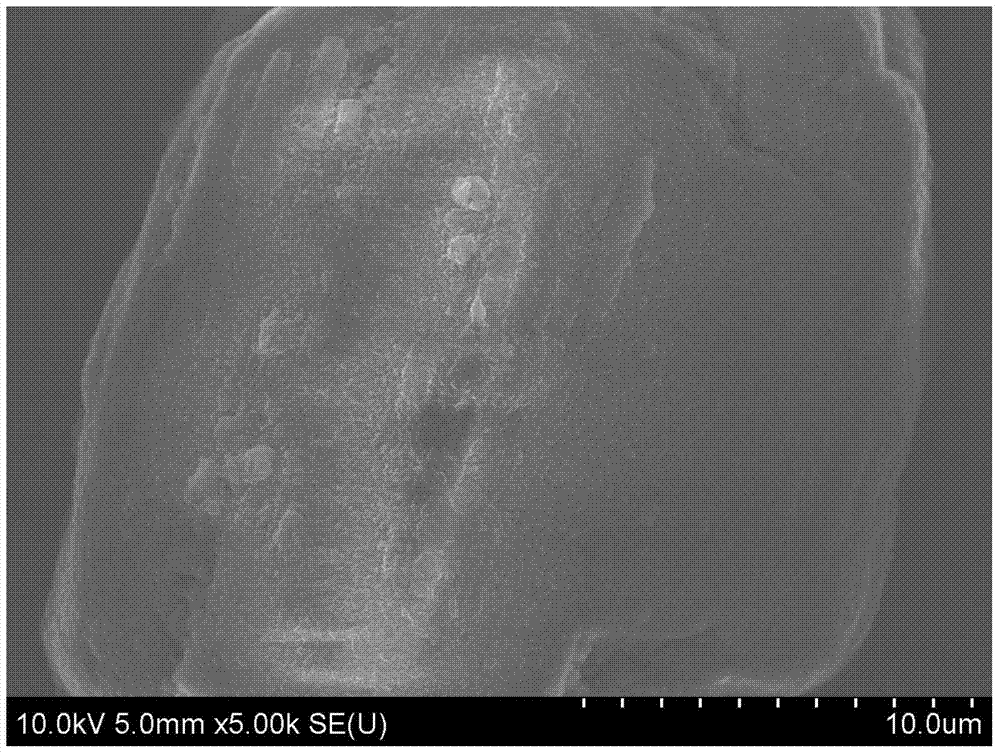

Image

Examples

preparation example Construction

[0026] A method for preparing low-viscosity microcapsule-encapsulated ammonium polyphosphate, comprising the following steps: in a reaction kettle, dispersing melamine formaldehyde resin prepolymer and ammonium polyphosphate in a solvent, adding a curing agent solution dropwise, and after dropping, Reflux reaction for 0.5~5h, then cool down to 40~50℃, then add end-capping agent dropwise, after the dropwise addition, keep the reaction for 0.5~3h, cool to room temperature, then filter, wash, drain, use rake dryer, in Dry under reduced pressure for 6-24 hours to obtain ammonium polyphosphate powder encapsulated in microcapsules.

[0027] The mass ratio of ammonium polyphosphate, melamine formaldehyde resin prepolymer and solvent is 1:0.05~0.20:1.5~3.0.

[0028] The curing agent is at least one of ammonium chloride, diammonium hydrogen phosphate, ammonium hydrogen phosphate, sodium dihydrogen phosphate, potassium dihydrogen phosphate acid salt, citric acid, and acetic acid.

[00...

Embodiment 1

[0035] In a 200L reactor with a stirring paddle and a reflux device, 20kg of melamine formaldehyde resin prepolymer CS303 and 200kg of ammonium polyphosphate were dispersed in a mixed solvent of 200kg of water and 100kg of acetone, and 0.1kg of curing agent was added dropwise. Ammonium chloride (made into a 20wt% aqueous solution), after the dropwise addition, seal the reaction kettle, raise the temperature to the reflux temperature, keep the temperature for 3 hours, then lower the temperature to 50°C, add 0.1kg methanol dropwise, complete the dropwise addition, keep the temperature for 1 hour, and react After finishing, it was cooled to room temperature, then centrifuged, washed with solvent, dried, matured and dried under reduced pressure at 80° C. for 6 hours using a rake dryer to obtain ammonium polyphosphate powder encapsulated in microcapsules.

Embodiment 2

[0037] In a 200L reactor with a stirring paddle and a reflux device, 10kg of melamine formaldehyde resin prepolymer 5830 and 200kg of ammonium polyphosphate were dispersed in 350kg of DMF solvent, and 0.2kg of curing agent diammonium hydrogen phosphate ( 20wt% aqueous solution), after the dropwise addition was completed, the reaction kettle was sealed, heated to the reflux temperature, kept for 2 hours, then cooled to 60°C, 0.1 kg of ethanol was added dropwise, the dropwise addition was completed, the temperature was kept for 1.5 hours, the reaction was completed, and the cooling After reaching room temperature, centrifuging, washing with solvent, drying, using a rake dryer, curing and drying under reduced pressure at 120° C. for 6 hours to obtain ammonium polyphosphate powder encapsulated in microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com