Back electrode of solar battery device, preparation method of back electrode and solar battery device

A solar cell and back electrode technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as mismatch, lower photoelectric conversion efficiency, and high interface material lattice, so as to reduce the density of interface defect states and improve photoelectric conversion Efficiency, the effect of reducing the surface recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

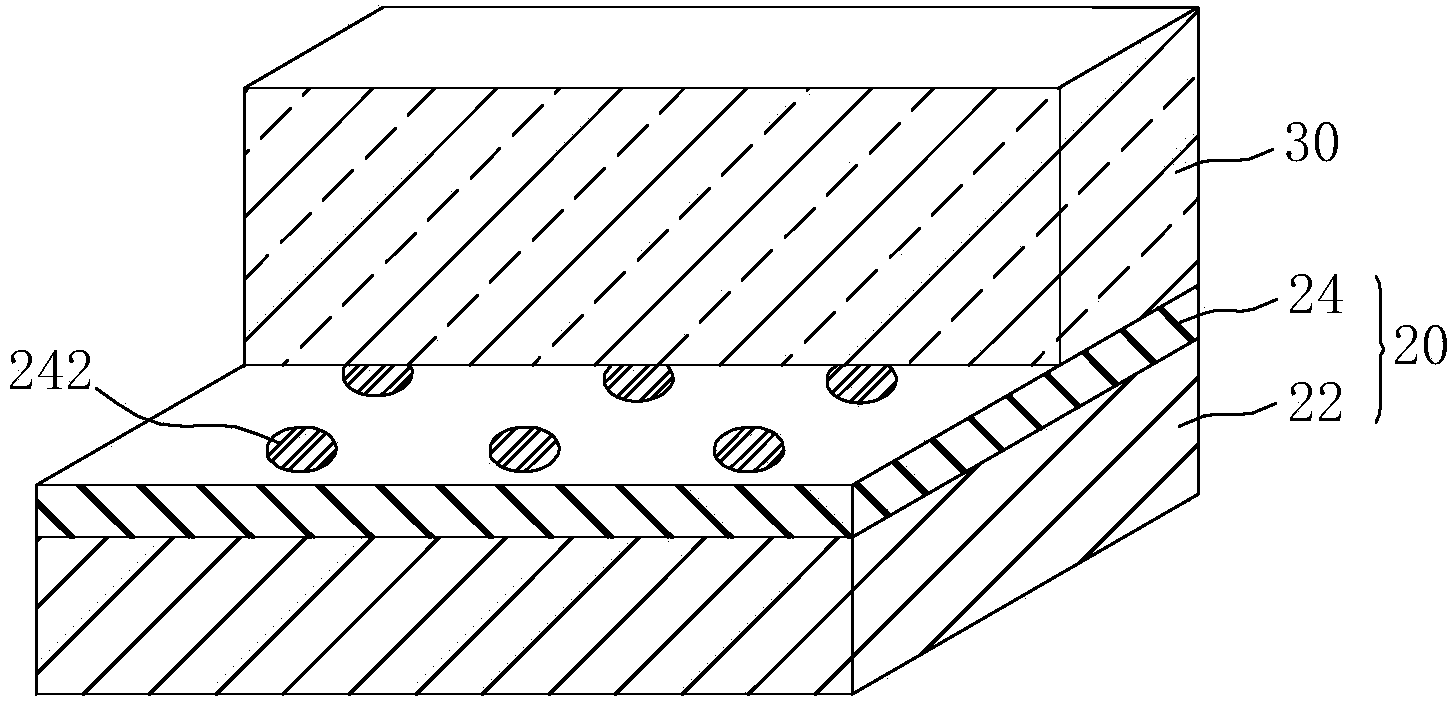

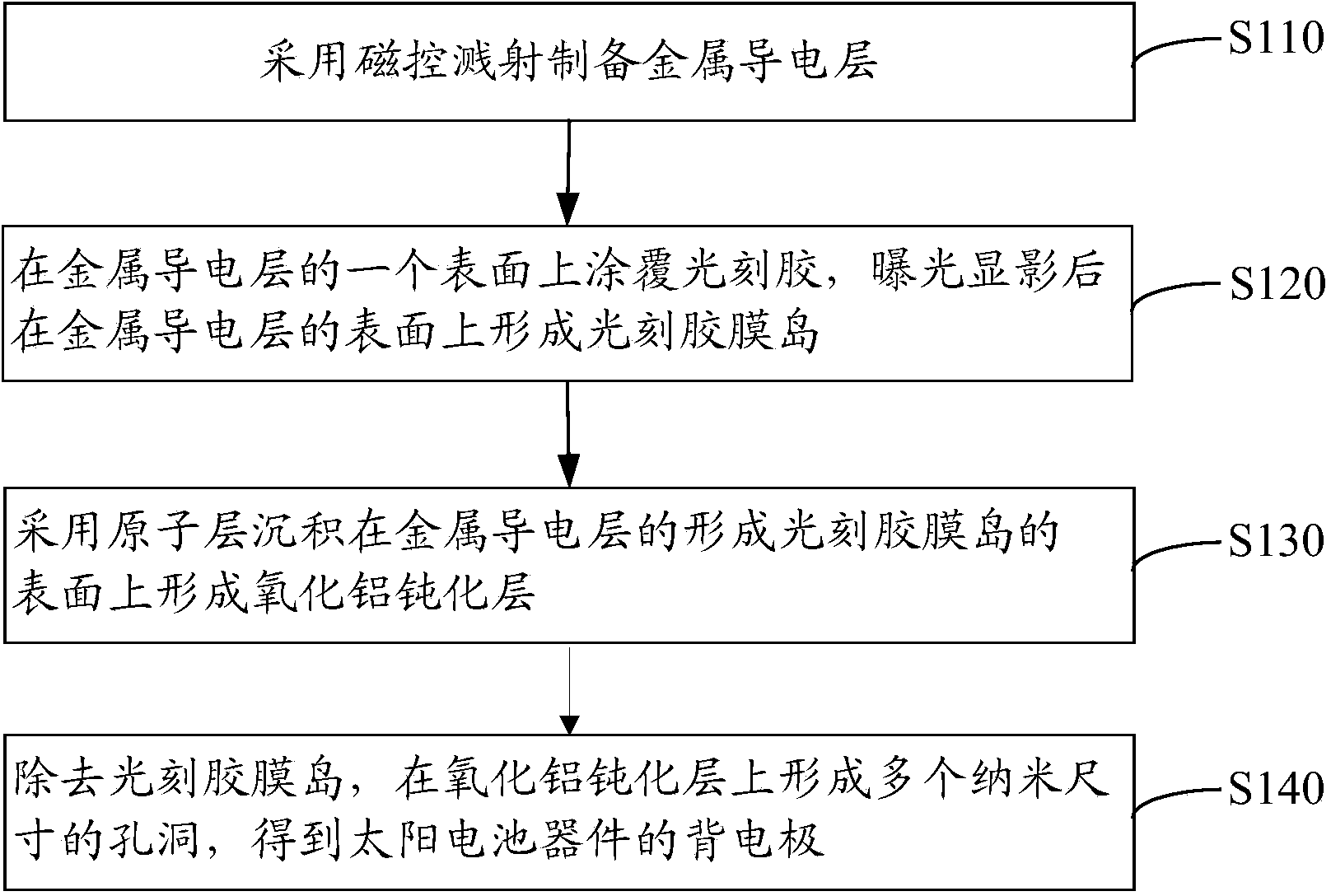

[0051] see image 3 , the preparation method of the back electrode of the solar cell device of an embodiment, comprises the following steps:

[0052] Step S110: Preparing a metal conductive layer by magnetron sputtering.

[0053] A substrate is provided, which can be a soda-lime glass substrate or other flexible material substrate (stainless steel foil, titanium foil or polyimide substrate, etc.).

[0054] After cleaning and drying the substrate, put it on the sample holder of the magnetron sputtering vacuum chamber, the vacuum degree of the magnetron sputtering vacuum chamber is 2×10 -4 After Pa, turn on the heating power of the sample holder, and maintain the sample holder at 250°C. Introduce argon or a mixed gas of argon and oxygen, adjust the flow meter to control the inflow rate of the gas to 12.5 sccm, and adjust the air pressure in the magnetron sputtering vacuum chamber to 0.1-1 Pa, preferably 0.16 Pa.

[0055] Adjust the sputtering power of molybdenum target or alu...

Embodiment 1

[0113] Fabrication of solar cell devices

[0114] (1) Provide a soda-lime glass substrate, clean and dry the soda-lime glass substrate and put it on the sample holder of the magnetron sputtering vacuum chamber, heat the temperature of the sample holder to 250°C, and the vacuum degree is 0.16Pa , with a power density of 4W / cm 2 Sputtering metal molybdenum onto the soda-lime glass substrate to form a metal conductive layer laminated on the soda-lime glass substrate with a thickness of 1 micron;

[0115] (2) Spin coat photoresist NR5-8000 on the metal conductive layer, spin coating speed 1000rpm, spin coating time 40 seconds, and then bake at 150°C for 10 minutes to cure the photoresist to form a layer on the metal conductive layer on a 15 µm thick photoresist layer. Expose and develop the photoresist layer with the designed mask. There are multiple circular holes on the mask plate, the diameter of each circular hole is 1 micron, the distance between the centers of the cross-s...

Embodiment 2

[0120] Fabrication of solar cell devices

[0121] (1) Provide a soda-lime glass substrate, clean and dry the soda-lime glass substrate and put it on the sample holder of the magnetron sputtering vacuum chamber, heat the temperature of the sample holder to 250°C, and the vacuum degree is 0.16Pa , with a power density of 4W / cm 2 Sputtering metal molybdenum onto the soda-lime glass substrate to form a metal conductive layer laminated on the soda-lime glass substrate with a thickness of 2 microns;

[0122] (2) Spin coat photoresist NR5-8000 on the metal conductive layer, spin coating speed 1000rpm, spin coating time 40 seconds, and then bake at 150°C for 10 minutes to cure the photoresist to form a layer on the metal conductive layer on a 15 µm thick photoresist layer. Expose and develop the photoresist layer with the designed mask. There are multiple circular holes on the mask plate, the diameter of each circular hole is 1.5 microns, the distance between the centers of the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com