Anatase titanium dioxide nano-rods and preparation method thereof

A technology of titanium dioxide and nano-titanium dioxide, which is applied in the field of nanomaterials, can solve the problems that electrode materials are not easy to collect electrons, limit the performance of photoelectrochemical devices, lack size and microscopic shape, etc., and achieve easy control of process parameters and high electron collection efficiency. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

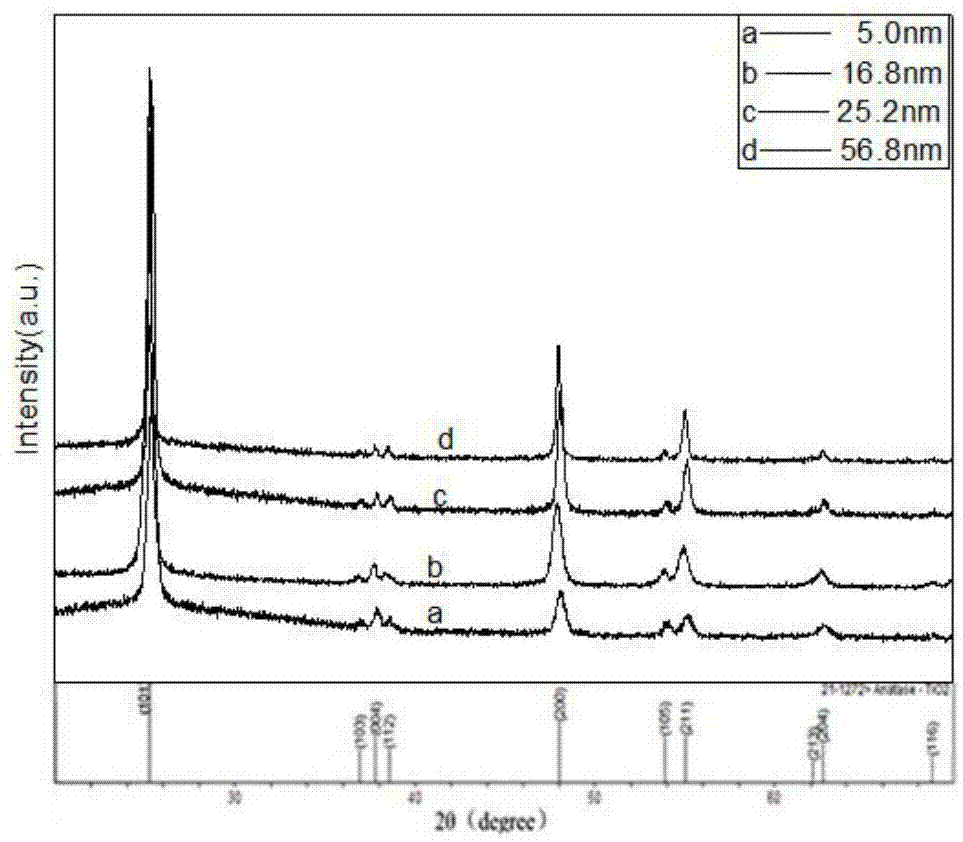

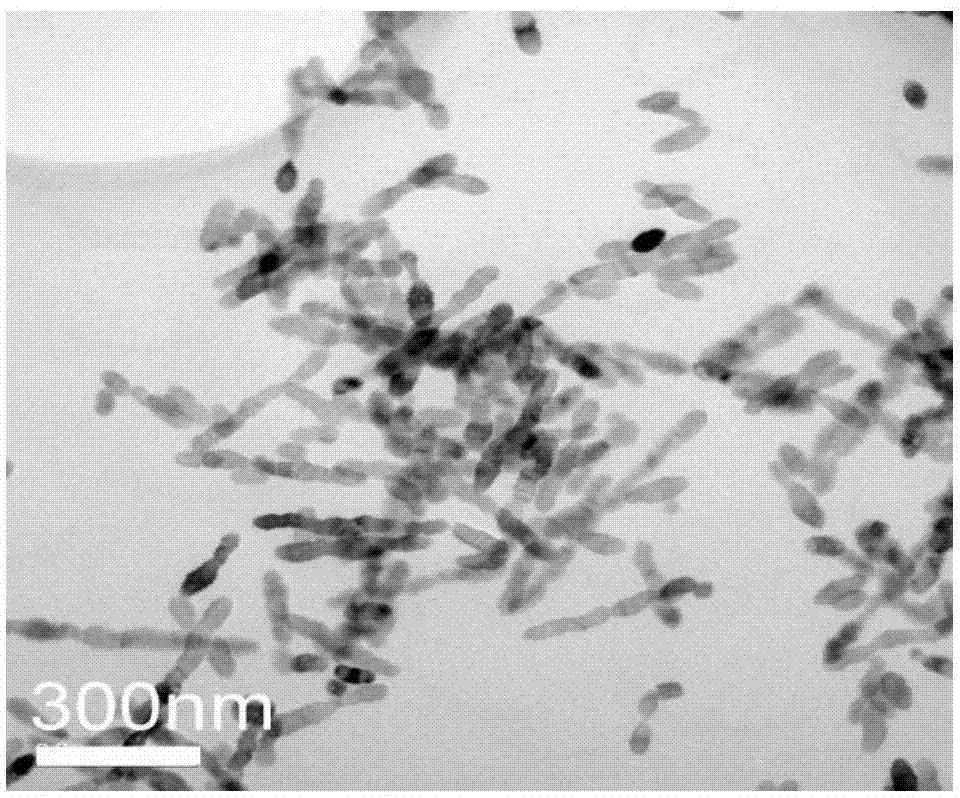

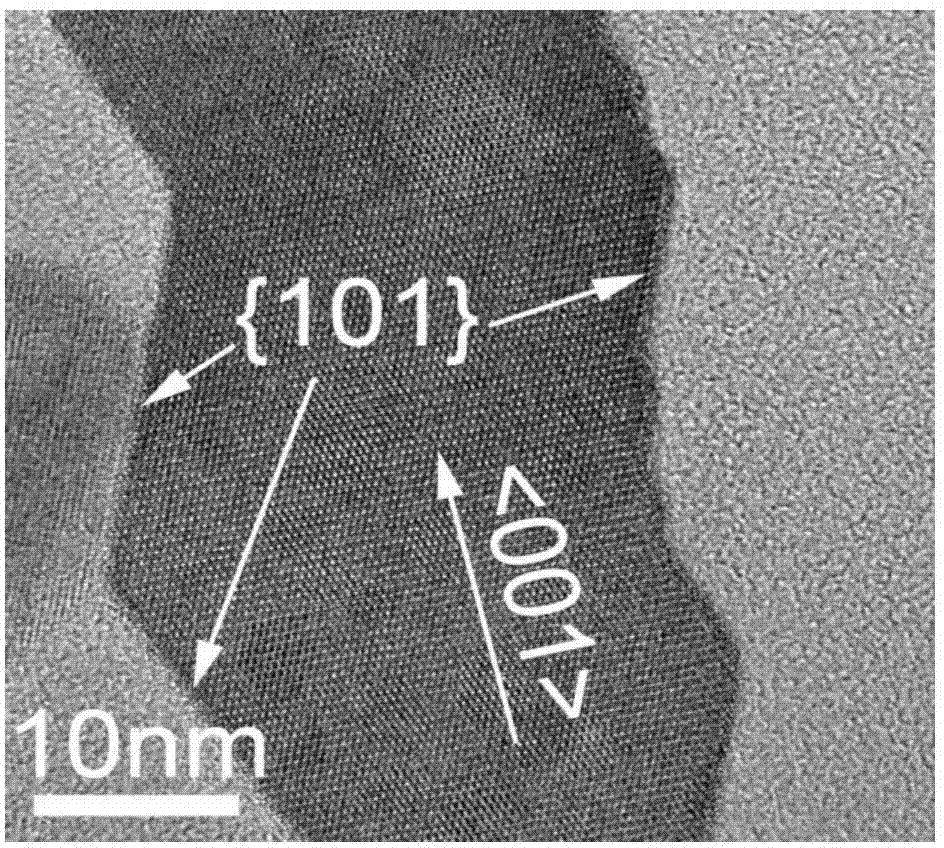

[0039] Fully mix 10mmol of isopropyl titanate with a small amount of ethylene glycol, slowly add the mixed solution to the mixed solution of ethylene glycol-water-ethanol containing 1.79ml tetrabutylammonium hydroxide solution, and finally keep the ethylene glycol in the reaction precursor The volume ratio of alcohol:water:ethanol is 15:1:14. Reflux with magnetic stirring for 1 hour under the condition of an oil bath at 85° C. until the reaction solution becomes completely clear. Then the reaction solution was transferred to a polytetrafluoroethylene hydrothermal kettle with a capacity of 100ml, reacted in an oven at 230°C for 24 hours, cooled to room temperature, centrifuged at 10,000 rpm, and washed 5 times with water and ethanol repeatedly. The coated film of the ethanol-wetted product was placed on a glass substrate, dried at 100°C for 30 minutes, and then heat-treated at 450°C for 1 hour. The specific surface area of the product is 144.8m 2 / g, the product morphology is...

example 2

[0041] The specific process is the same as that in Example 1, except that the volume ratio of ethylene glycol:water:ethanol in the reaction precursor is finally kept at 1:1:0. The specific surface area of the product is 105.5m 2 / g, the product morphology is as Figure 5 As shown, it shows that the aspect ratio or the orientation bonding growth mode can be controlled by adjusting the solvent ratio.

example 3

[0043] Fully mix 30mmol isopropyl titanate with a small amount of ethylene glycol, slowly add the mixed solution to the mixed solution of ethylene glycol-water containing 4.47ml tetramethylammonium hydroxide solution, and finally keep the ethylene glycol in the reaction precursor The volume ratio of alcohol:water is 1:1. Under the condition of an oil bath at 85° C., the mixture was magnetically stirred and refluxed for 3 hours until the reaction liquid became completely clear. Then the reaction solution was transferred to a polytetrafluoroethylene hydrothermal kettle with a capacity of 100ml, reacted in an oven at 230°C for 24 hours, cooled to room temperature, centrifuged at 8000 rpm, and washed repeatedly with water and ethanol for 5 times. The coated film of the ethanol-wetted product was placed on a glass substrate, dried at 100°C for 30 minutes, and then heat-treated at 450°C for 1 hour. The specific surface area of the product is 57.0m 2 / g, the product morphology is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com