Method for removing halogenated nitrogen-containing sterilization side products from drinking water

A technology for disinfection by-products and drinking water, applied in water pollutants, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as harsh technical conditions, and achieve the effect of low price, mild conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

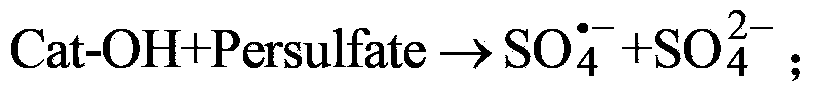

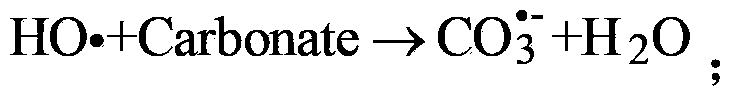

Method used

Image

Examples

Embodiment 1

[0039] Observe whether the drinking water that needs to remove halogenated nitrogen-containing disinfection by-products is clean drinking water, and confirm whether the water body is clear after standing. If it is found that the water body after standing still has sediment and is not clean, then simple pretreatment of the water body is required, such as sand filtration, activated carbon adsorption, etc.

[0040] After confirming that the water body is clean, add hydrogen peroxide, potassium persulfate and sodium bicarbonate to the water body, wherein the content of hydrogen peroxide in the water body is 20 μM, the content of potassium persulfate in the water body is 25 μM, and the content of sodium bicarbonate in the water body is 10 mM. After fully mixing, the pH is adjusted to be 7, and then the mixed solution is transported to the catalyst bed (column, internal diameter 5cm) with a pump at 20mL / min for contact reaction. The catalyst is zeolite (the surface hydroxyl density i...

Embodiment 2

[0043] After confirming that the water to be treated is clean, use a total organic carbon detector to detect the content of background organic matter (such as humic acid, fulvic acid, etc.) in the water. If the content is greater than 4mg / L, hydrogen peroxide and sodium persulfate must be injected Add it to the water body so that the concentration of hydrogen peroxide in the water body is 40 μM, and the concentration of sodium persulfate in the water body is 50 μM, mix for 10 minutes, then add sodium bicarbonate and mix well, so that the concentration of sodium bicarbonate in the water body is 10 mM, and adjust the pH to 7 , and then pump the mixed solution to the catalyst bed (column, inner diameter 5cm) with a pump at 20mL / min for contact reaction, the catalyst is γ-Al 2 o 3 (the surface hydroxyl density is 8.0×10 -5 M·m 2 , water contact angle of 48 degrees, purchased from Pingxiang City Huihua Packing Co., Ltd.), particle size of 40 mesh, filling height of 20cm, empty be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com