Special zirconium-aluminium composite ground micro-powder for optoelectronic industry and production method for same

A technology in the electronics industry and production methods, applied in chemical instruments and methods, and other chemical processes, can solve problems such as high prices, low production costs, and unacceptable markets, and achieve reduced surface energy, high grinding efficiency, and avoid hard grinding. crisp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Give an embodiment below and describe in detail as follows:

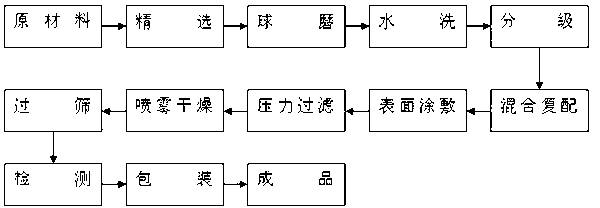

[0029] The steps of the preparation method of the present invention are as follows:

[0030] one,The two main raw materials, fused alumina and zirconium silicate, are selected separately to ensure good crystallization, white color, and no impurities. The content of alumina in the fused alumina raw material should be greater than 99%, and the particle size should be less than 300 mesh, the content of zirconium silicate in the zirconium silicate raw material should be greater than 98%, and the particle size should be less than 350 mesh;

[0031] two, Ball milling, rounding and water washing: A: Alumina ball milling: use stainless steel grinding balls; the weight ratio of the material to the ball is 3:1, controlled by PLC, the grinding-time speed curve is a sinusoidal curve, the maximum speed of the ball mill is 4 revolutions per minute, One grinding cycle is one hour;

[0032] Circularization, the rounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com